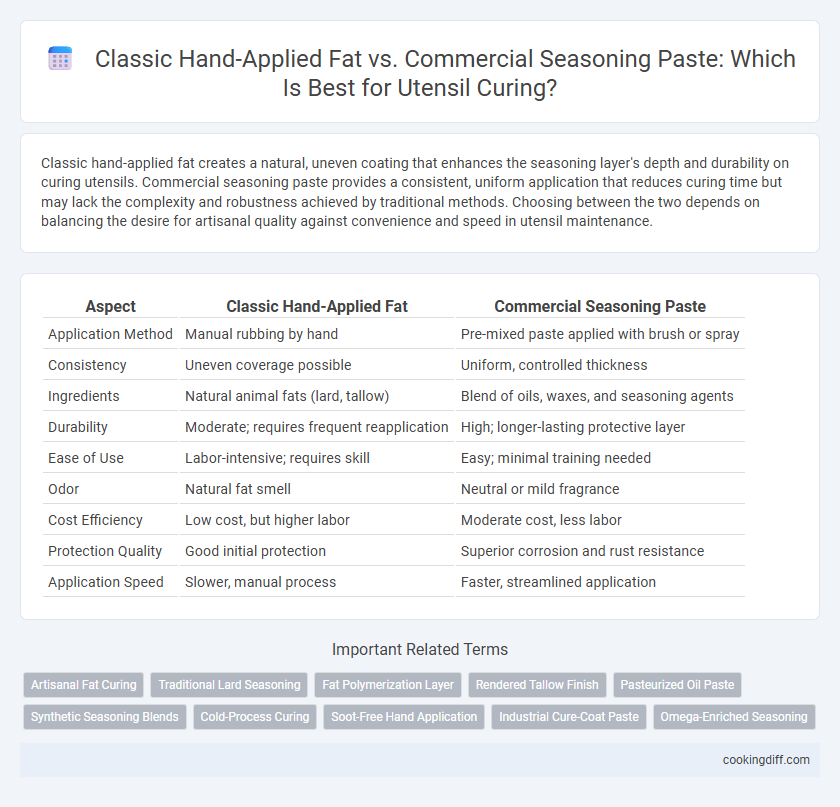

Classic hand-applied fat creates a natural, uneven coating that enhances the seasoning layer's depth and durability on curing utensils. Commercial seasoning paste provides a consistent, uniform application that reduces curing time but may lack the complexity and robustness achieved by traditional methods. Choosing between the two depends on balancing the desire for artisanal quality against convenience and speed in utensil maintenance.

Table of Comparison

| Aspect | Classic Hand-Applied Fat | Commercial Seasoning Paste |

|---|---|---|

| Application Method | Manual rubbing by hand | Pre-mixed paste applied with brush or spray |

| Consistency | Uneven coverage possible | Uniform, controlled thickness |

| Ingredients | Natural animal fats (lard, tallow) | Blend of oils, waxes, and seasoning agents |

| Durability | Moderate; requires frequent reapplication | High; longer-lasting protective layer |

| Ease of Use | Labor-intensive; requires skill | Easy; minimal training needed |

| Odor | Natural fat smell | Neutral or mild fragrance |

| Cost Efficiency | Low cost, but higher labor | Moderate cost, less labor |

| Protection Quality | Good initial protection | Superior corrosion and rust resistance |

| Application Speed | Slower, manual process | Faster, streamlined application |

Introduction to Utensil Curing Methods

Utensil curing methods play a crucial role in enhancing the durability and performance of cooking tools. Classic hand-applied fat involves manually rubbing animal fat onto utensils to create a protective, non-stick layer.

Commercial seasoning paste offers a standardized and convenient alternative, containing optimized blends of oils and waxes for consistent curing results. This method ensures even coating and accelerated curing times, improving the utensil's resistance to rust and wear. Both techniques enhance the lifespan of cookware by forming protective barriers against moisture and oxidation.

Understanding Classic Hand-applied Fats

What distinguishes Classic Hand-applied Fat from Commercial Seasoning Paste in utensil curing? Classic Hand-applied Fats provide a natural, uneven coating that enhances flavor and offers a traditional curing experience. This method allows better control over fat distribution, promoting deep penetration and a durable seasoned surface.

What is Commercial Seasoning Paste?

Commercial seasoning paste is a specially formulated blend designed to enhance the curing process of utensils by creating a durable, protective layer. It offers consistent application and improved adhesion compared to classic hand-applied fat methods.

- Enhanced durability - Commercial seasoning paste forms a stronger, longer-lasting protective coating on cookware surfaces.

- Improved consistency - Unlike hand-applied fat, the paste ensures uniform coverage and thickness.

- Time-efficient application - The paste reduces curing time by optimizing the seasoning process with precise ingredient ratios.

Key Ingredients: Natural Fats vs Synthetic Pastes

Classic hand-applied fat for utensil curing uses natural ingredients such as animal tallow, beeswax, and vegetable oils, which penetrate the metal surface to create a durable, protective layer. These natural fats enhance the utensil's longevity by forming a breathable barrier that prevents rust and corrosion.

Commercial seasoning pastes often contain synthetic compounds like silicones, polymers, and petroleum derivatives, designed for quick application and uniform coverage. Although convenient, these synthetic pastes may lack the deep conditioning properties of natural fats, potentially reducing the curing's effectiveness over time.

Application Techniques: Traditional vs Modern Approaches

Classic hand-applied fat involves manually rubbing animal fats onto utensils, allowing natural oils to penetrate and provide a durable, non-stick surface. Commercial seasoning paste uses engineered blends for uniform application and faster curing, enhancing efficiency in modern cooking environments.

- Traditional manual rubbing - Allows precise control over fat application, fostering a seasoned layer that improves with use.

- Commercial seasoning paste - Offers consistent coverage, reducing labor time and standardizing utensil preparation.

- Penetration depth - Hand-applied fats typically absorb deeper into porous materials, while pastes form a surface coating optimized for quick curing.

Performance and Durability of Each Method

Classic hand-applied fat creates a natural, robust seasoning layer that enhances utensil non-stick performance and longevity. Commercial seasoning paste offers consistent coverage and quicker curing time, but may lack the depth of durability found in traditional methods.

- Classic Hand-applied Fat - Builds a thicker, more resilient seasoning that improves with use over time.

- Commercial Seasoning Paste - Provides uniform application, reducing curing errors and surface imperfections.

- Durability Comparison - Hand-applied fat seasoning tends to resist flaking and wear better under heavy use.

Choosing between these methods depends on balancing curing efficiency against long-term durability needs.

Impact on Flavor and Cooking Results

Classic hand-applied fat creates a natural, rich layer that enhances the utensil's non-stick properties and imparts a subtle, authentic flavor to dishes. Commercial seasoning paste offers a consistent coating with added spices, which can introduce bold, uniform flavors but may mask the utensil's natural seasoning over time. Flavor development and cooking results depend on personal preference, with hand-applied fat favoring nuanced taste profiles and seasoning paste delivering immediate, pronounced flavor impact.

Safety, Health, and Allergen Considerations

| Aspect | Classic Hand-applied Fat | Commercial Seasoning Paste |

|---|---|---|

| Safety | Natural fats may harbor bacteria if not stored properly, requiring thorough heating during application to ensure sterilization. | Formulated to include preservatives and antimicrobial agents, reducing microbial risks and enhancing surface safety. |

| Health | Contains saturated fats and cholesterol that can contribute to health concerns if overused; however, offers a natural composition without synthetic additives. | Often designed with balanced lipid profiles and may include added vitamins or antioxidants, aiming to promote utensil longevity without unhealthy residue. |

| Allergen Considerations | Potential allergens depend on fat source, commonly animal-based (e.g., lard) which may affect those with animal product sensitivities. | Formulas vary widely; must be checked for soy, gluten, nuts, or other allergenic ingredients, making ingredient transparency critical for safe use. |

Cost and Accessibility Comparison

Classic hand-applied fat requires raw materials like animal fats or oils, which may be less expensive but involve more labor and time, impacting overall cost-effectiveness. This method is highly accessible, as fats are widely available and do not require specialized equipment, making it suitable for small-scale or traditional curing.

Commercial seasoning paste comes at a higher initial cost due to industrial processing and packaging but reduces labor time and ensures consistent application, potentially saving costs in large-scale operations. Accessibility can be limited by supply chains and vendor availability, especially in remote areas, affecting its practicality for some users.

Related Important Terms

Artisanal Fat Curing

Artisanal fat curing using classic hand-applied fat methods enhances the utensil's natural non-stick properties and imparts a rich, authentic flavor profile often lost with commercial seasoning pastes. This traditional technique promotes deeper fat absorption into cast iron or carbon steel surfaces, ensuring durable seasoning layers that improve cooking performance and longevity.

Traditional Lard Seasoning

Traditional lard seasoning, used in classic hand-applied fat curing, enhances cookware durability by creating a natural non-stick surface that penetrates metal pores effectively. Unlike commercial seasoning pastes, lard offers superior heat resistance and a time-tested, organic method that improves with repeated use and high-temperature curing.

Fat Polymerization Layer

Classic hand-applied fat creates a natural polymerization layer that enhances the utensil's non-stick properties and corrosion resistance. Commercial seasoning pastes often contain additives that accelerate curing but may result in a thinner, less durable fat polymerization layer.

Rendered Tallow Finish

Rendered tallow finish in classic hand-applied fat creates a natural, durable barrier that enhances utensil longevity by sealing pores and preventing moisture infiltration. Commercial seasoning paste often contains additives that may provide a uniform coating, but lack the deep penetration and traditional protection qualities of rendered tallow.

Pasteurized Oil Paste

Pasteurized oil paste offers superior preservation and enhanced flavor absorption compared to classic hand-applied fat, ensuring a more uniform and durable curing layer on utensils. Its commercial formulation optimizes antimicrobial properties and oxidative stability, extending shelf life and maintaining utensil quality.

Synthetic Seasoning Blends

Synthetic seasoning blends in commercial seasoning pastes offer consistent curing results by providing uniform fat absorption and enhanced flavor retention compared to classic hand-applied fat methods. Their precise formulation improves utensil durability and reduces curing time, making them a preferred choice for industrial and high-volume applications.

Cold-Process Curing

Classic hand-applied fat creates a natural barrier that slowly conditions utensils during cold-process curing, enhancing durability and flavor retention. Commercial seasoning paste offers a faster, more uniform cure with consistent chemical properties that optimize protection and reduce curing time for metal cookware.

Soot-Free Hand Application

Classic hand-applied fat offers a soot-free curing process by evenly coating utensils without burning impurities, preserving cookware integrity and enhancing non-stick properties. Commercial seasoning paste often contains additives that can leave residues and generate soot when exposed to high heat, reducing overall surface quality and durability during seasoning.

Industrial Cure-Coat Paste

Industrial Cure-Coat Paste offers superior adhesion and uniform seasoning compared to classic hand-applied fats, ensuring a durable, rust-resistant coating on cooking utensils. Its formulation enhances heat distribution and creates a non-stick surface, optimizing utensil longevity and performance in commercial kitchens.

Classic Hand-applied Fat vs Commercial Seasoning Paste for utensil curing. Infographic

cookingdiff.com

cookingdiff.com