Hot curing enhances texture by rapidly denaturing proteins, resulting in a firmer, more resilient bite, while intensifying umami through concentrated flavors. Shio koji curing gently breaks down proteins and fats using natural enzymes, creating a tender texture with a subtle, complex umami depth. Comparing both methods, hot curing delivers a robust taste and texture contrast, whereas shio koji offers a delicate balance of softness and nuanced savory richness.

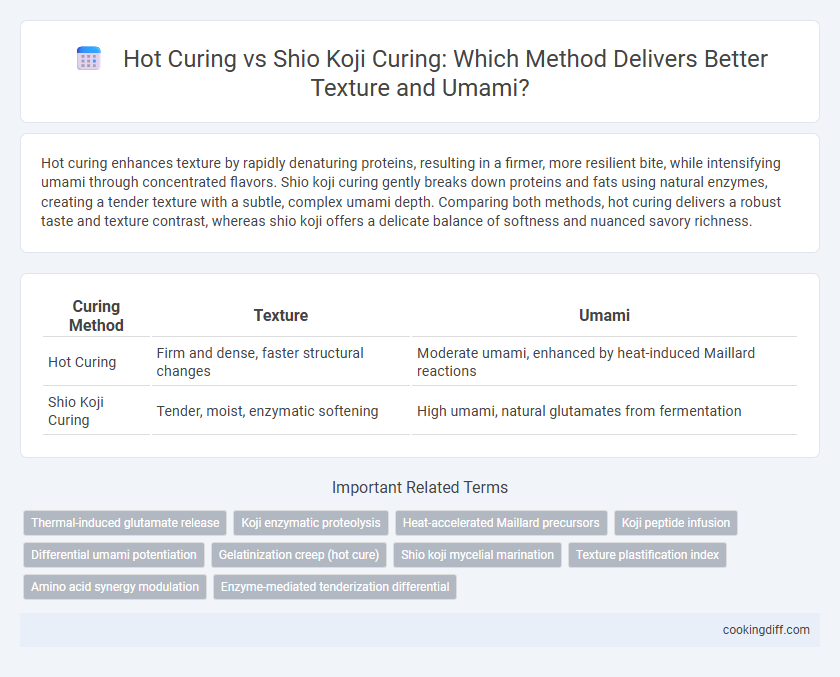

Table of Comparison

| Curing Method | Texture | Umami |

|---|---|---|

| Hot Curing | Firm and dense, faster structural changes | Moderate umami, enhanced by heat-induced Maillard reactions |

| Shio Koji Curing | Tender, moist, enzymatic softening | High umami, natural glutamates from fermentation |

Understanding Hot Curing and Shio Koji Curing

Hot curing uses elevated temperatures to accelerate protein denaturation, resulting in a firm texture and intensified umami through Maillard reactions. In contrast, shio koji curing employs enzymes from fermented rice malt to gently break down proteins and sugars, enhancing tenderness and naturally boosting umami compounds.

Understanding hot curing reveals how heat modifies muscle fibers quickly, producing a distinct chewiness while developing deep savory flavors. Shio koji curing leverages enzymatic activity at lower temperatures to create a delicate, moist texture that amplifies amino acids responsible for umami. Both methods uniquely influence texture and taste, offering diverse culinary applications depending on desired outcomes.

Key Differences in Curing Techniques

Hot curing involves applying heat to accelerate protein denaturation, resulting in a firmer texture, while shio koji curing utilizes enzymes from fermented rice to enhance umami and tenderize meat naturally. The enzymatic action in shio koji produces a deeper flavor profile without the toughness that heat curing can sometimes induce.

- Heat Application - Hot curing uses elevated temperatures to alter texture quickly.

- Enzymatic Reaction - Shio koji relies on enzymes to break down proteins for increased tenderness and umami.

- Flavor Development - Shio koji curing imparts a richer, more complex umami flavor compared to the often simpler profile from hot curing.

The Science of Umami: Hot Curing vs Shio Koji

How do hot curing and shio koji curing differ in enhancing texture and umami? Hot curing denatures proteins rapidly with heat, resulting in a firmer texture but less complex umami development. Shio koji curing utilizes enzymes from Aspergillus oryzae to break down proteins into amino acids, intensifying umami flavor while preserving a tender, moist texture.

Texture Transformation: Comparing Results

Hot curing rapidly alters the protein structure, resulting in a firmer texture, while shio koji curing uses enzymatic activity to tenderize meat and develop complex umami flavors. Texture transformation with shio koji is subtler and more nuanced compared to the immediate firming effect of hot curing.

- Hot curing firmness - Denatures proteins quickly, producing a dense, chewy texture.

- Shio koji enzymatic tenderization - Breaks down muscle fibers gradually, enhancing softness and moisture retention.

- Umami enhancement - Shio koji fermentation releases amino acids that significantly boost savory taste.

Choosing between hot curing and shio koji depends on whether a firmer texture or enriched umami complexity is desired.

Flavor Development Through Hot Curing

Hot curing enhances flavor development by accelerating protein breakdown, creating a tender texture with rich umami notes. Higher temperatures facilitate the Maillard reaction, intensifying savory compounds that define complex taste profiles. Compared to shio koji curing, hot curing delivers a more pronounced, robust flavor ideal for bold culinary applications.

Umami Enhancement with Shio Koji Curing

Hot curing uses high temperatures to denature proteins quickly, resulting in a firmer texture but a more straightforward flavor profile. In contrast, shio koji curing employs fermented rice malt enzymes to break down proteins and fats slowly, enhancing the umami complexity and tenderness of the meat.

Shio koji's enzymatic activity releases glutamates and amino acids that intensify savory flavors, creating a rich and nuanced taste experience. This method also improves moisture retention, contributing to a juicier texture while deepening the overall umami sensation.

Protein Breakdown: Enzymatic Actions in Each Method

Hot curing intensifies protein denaturation through heat, rapidly breaking down muscle fibers to enhance texture while moderately releasing umami compounds. Shio koji curing leverages enzymatic activity from Aspergillus oryzae, promoting gradual protein hydrolysis that enriches umami and tenderizes meat over time.

- Heat-induced denaturation - Hot curing uses elevated temperatures to disrupt protein structures, improving firmness and chewiness.

- Enzymatic proteolysis - Shio koji introduces proteases that slowly hydrolyze proteins, increasing free amino acids responsible for umami flavor.

- Texture and flavor balance - Hot curing yields a firmer texture with moderate umami, while shio koji produces a tender texture with enhanced savory depth.

Applications in Different Types of Proteins

Hot curing accelerates protein denaturation and moisture loss, resulting in a firmer texture ideal for beef and pork products like ham and bacon. This method enhances surface umami through Maillard reactions but may reduce internal juiciness in delicate proteins such as fish.

Shio koji curing utilizes enzymes from Aspergillus oryzae to break down proteins and starches, tenderizing meats like chicken and seafood while intensifying umami flavor internally. Its gentle enzymatic action preserves moisture and creates a soft, succulent texture optimal for delicate protein applications.

Taste Tests: Consumer Preferences

Hot curing enhances texture by creating a firmer, more cooked consistency, while shio koji curing promotes a tender, moist texture with a natural umami boost derived from fermented enzymes. Taste tests reveal that consumers often prefer shio koji cured products for their complex, savory flavor profile and pleasant mouthfeel. The natural enzymatic activity in shio koji results in a richer taste experience compared to the straightforward, salt-driven flavor of hot curing.

Related Important Terms

Thermal-induced glutamate release

Hot curing enhances thermal-induced glutamate release by breaking down proteins at elevated temperatures, intensifying umami and creating a firmer texture. In contrast, shio koji curing relies on enzymatic fermentation, gently releasing glutamates to produce a tender texture with a nuanced umami profile.

Koji enzymatic proteolysis

Hot curing uses heat to denature proteins rapidly, resulting in a firmer texture but limited enzymatic breakdown, while shio koji curing leverages koji's enzymatic proteolysis to gently tenderize muscle fibers and enhance umami through natural amino acid release. Koji enzymes like proteases and peptidases break down proteins into peptides and free amino acids, significantly improving meat's softness and depth of flavor without the toughening effect of thermal treatment.

Heat-accelerated Maillard precursors

Hot curing rapidly accelerates Maillard reaction precursors through elevated temperatures, enhancing protein denaturation and producing a firmer texture with intensified umami flavors. In contrast, shio koji curing utilizes enzymatic activity to gradually break down proteins and starches, resulting in a tender texture and complex umami development without the direct application of heat.

Koji peptide infusion

Hot curing accelerates protein denaturation, resulting in a firmer texture but limited umami development, whereas shio koji curing enhances umami by infusing peptides through enzymatic breakdown of proteins, creating a tender texture with rich, savory depth. Koji peptides released during shio koji fermentation significantly improve flavor complexity and moisture retention compared to thermal methods.

Differential umami potentiation

Hot curing enhances texture by denaturing proteins quickly, creating a firmer bite, while shio koji curing uses enzymes from Aspergillus oryzae to break down proteins slowly, resulting in a tender texture with amplified umami through increased free amino acids and nucleotides. Differential umami potentiation in shio koji curing arises from its enzymatic activity that elevates glutamate and inosinate concentrations, synergistically boosting savory flavor beyond the effects of heat-driven methods.

Gelatinization creep (hot cure)

Hot curing induces gelatinization creep, enhancing protein denaturation and resulting in a firmer texture with intensified umami through concentrated amino acids. Shio koji curing utilizes enzymatic fermentation to break down proteins gently, producing a tender texture and complex umami without the structural changes caused by heat-induced gelatinization.

Shio koji mycelial marination

Shio koji curing uses enzymes from Aspergillus oryzae mycelia to break down proteins and fats, resulting in a tender texture and enhanced umami flavor through natural glutamate release. Hot curing, by contrast, relies on heat and salt to preserve, often producing a firmer texture but less complex umami development compared to the enzymatic action of shio koji mycelial marination.

Texture plastification index

Hot curing enhances meat texture through rapid protein denaturation, resulting in a higher plastification index indicative of improved tenderness and juiciness. Shio koji curing promotes enzymatic breakdown of muscle fibers, increasing umami flavors while maintaining moderate plastification index values, balancing softness with optimal moisture retention.

Amino acid synergy modulation

Hot curing intensifies texture firmness through protein denaturation while promoting umami via Maillard reaction products, whereas shio koji curing enhances amino acid synergy by enzymatic breakdown of proteins into glutamic acid and peptides, resulting in a tender texture and complex umami depth. The modulation of amino acid profiles in shio koji curing specifically elevates umami intensity by increasing free glutamate and synergistic amino acids like glycine and alanine, creating a balanced savory flavor distinct from the robust taste developed in hot curing.

Hot curing vs shio koji curing for texture and umami. Infographic

cookingdiff.com

cookingdiff.com