Campfire curing imparts a traditional smoky flavor and creates a natural hardened surface on cookware, ideal for preserving seasoning in outdoor settings. Induction stovetop seasoning offers precise temperature control, ensuring even oil polymerization for a smooth, durable coating that requires less frequent maintenance. Regular use of induction stovetop seasoning results in a more consistent, easy-to-maintain seasoning layer compared to the unpredictable heat of campfire curing.

Table of Comparison

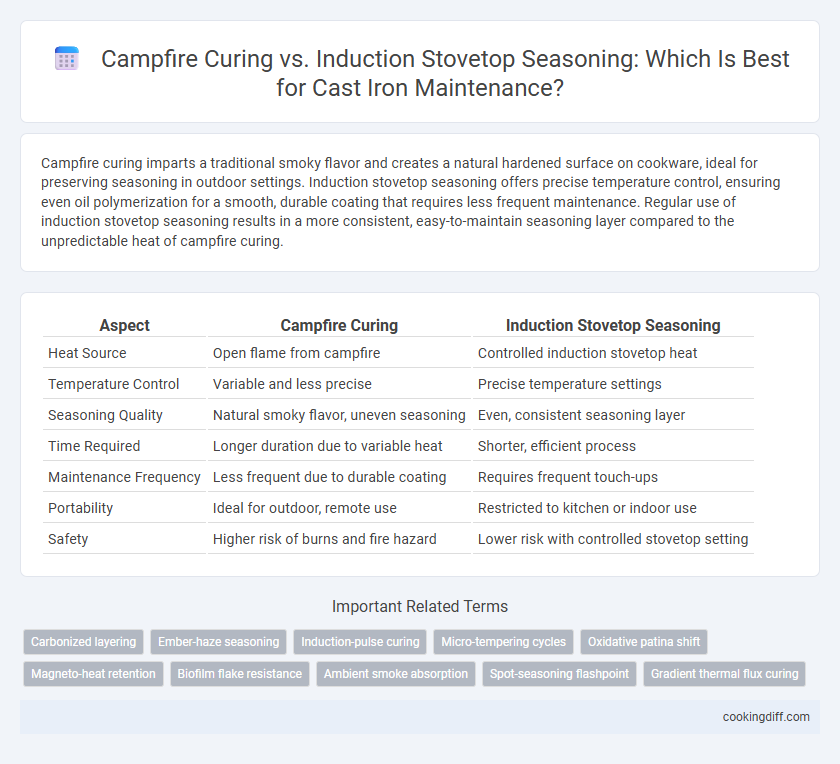

| Aspect | Campfire Curing | Induction Stovetop Seasoning |

|---|---|---|

| Heat Source | Open flame from campfire | Controlled induction stovetop heat |

| Temperature Control | Variable and less precise | Precise temperature settings |

| Seasoning Quality | Natural smoky flavor, uneven seasoning | Even, consistent seasoning layer |

| Time Required | Longer duration due to variable heat | Shorter, efficient process |

| Maintenance Frequency | Less frequent due to durable coating | Requires frequent touch-ups |

| Portability | Ideal for outdoor, remote use | Restricted to kitchen or indoor use |

| Safety | Higher risk of burns and fire hazard | Lower risk with controlled stovetop setting |

Introduction to Campfire Curing and Induction Stovetop Seasoning

Campfire curing involves using the natural heat and smoke from an open flame to season and preserve cast iron cookware, enhancing flavor and rust resistance. This traditional method infuses a distinct smoky aroma while gradually building a durable seasoning layer.

Induction stovetop seasoning utilizes precise, consistent heat generated by the induction cooktop to create a controlled environment for curing cast iron. This modern technique allows for even seasoning development and quicker maintenance without smoke exposure.

Key Differences Between Campfire and Induction Methods

Campfire curing infuses cast iron with uneven heat distribution, creating a rustic, smoky flavor while induction stovetop seasoning offers precise temperature control, ensuring a consistent, even seasoning layer. Campfire methods rely on open flames and natural elements, whereas induction utilizes electromagnetic fields for efficient heat generation.

Campfire curing can introduce unique seasoning imperfections that enhance the pan's character, but it risks overheating or under-curing due to variable heat. Induction stovetop seasoning provides a safer, cleaner process with the ability to maintain steady heat, reducing the chance of damage. Both methods aim to build a durable non-stick surface but differ significantly in heat control, environment, and seasoning quality.

Essential Equipment for Each Curing Technique

Campfire curing requires durable, heat-resistant tools to withstand open flames, while induction stovetop seasoning depends on precise temperature control via compatible cookware. Both methods necessitate equipment tailored to their heat source for optimal maintenance results.

- Campfire curing essentials - Use cast iron pots and heat-safe gloves designed for high, uneven heat distribution.

- Induction stovetop seasoning tools - Employ induction-ready pans with flat bottoms for efficient energy transfer and temperature regulation.

- Maintenance accessories - Both methods benefit from steel scrapers and natural oils to preserve surface seasoning and remove residue.

Temperature Control: Campfire vs Induction Stovetop

Campfire curing relies on inconsistent heat from open flames, making precise temperature control difficult and often resulting in uneven seasoning of cookware. Induction stovetop seasoning offers precise, adjustable temperature settings that maintain consistent heat, ensuring an even cure and longer-lasting seasoning.

- Campfire Heat Variability - The open flame produces fluctuating temperatures that can cause hot spots and uneven seasoning.

- Induction Temperature Precision - Induction stovetops allow for exact temperature adjustments to prevent overheating or underheating.

- Heat Distribution - Induction cooking provides uniform heat distribution that promotes consistent seasoning layers.

Temperature control on an induction stovetop optimizes maintenance and extends the life of cookware seasoning.

Step-by-Step Guide to Campfire Curing

Campfire curing involves heating the cookware over an open flame to polymerize oil and create a durable, non-stick layer. Begin by cleaning the pan thoroughly, applying a thin coat of high-smoke point oil such as flaxseed or grapeseed, and placing it over glowing embers for 10-15 minutes per side. This traditional method enhances seasoning depth and longevity compared to the quicker induction stovetop seasoning, which uses controlled heat but may result in thinner layers.

Step-by-Step Guide to Induction Stovetop Seasoning

| Step 1: Clean the skillet thoroughly with warm water and mild soap, then dry completely to ensure no residue interferes with seasoning. |

| Step 2: Apply a thin, even layer of high-smoke-point oil, such as flaxseed or grapeseed oil, to the entire surface of the pan using a lint-free cloth. |

| Step 3: Heat the skillet on an induction stovetop set to medium-high for 10-15 minutes, allowing the oil to polymerize and create a durable, non-stick coating. |

| Step 4: Let the skillet cool completely before wiping off any excess oil, and repeat the process 2-3 times for optimal seasoning maintenance. |

Durability and Maintenance of the Seasoned Cookware

Campfire curing creates a robust, uneven seasoning layer due to high, fluctuating heat that enhances durability but requires more frequent maintenance to prevent flaking. Induction stovetop seasoning offers precise temperature control, producing a smoother, more uniform seasoning layer that is easier to maintain and less prone to damage. Regular upkeep with proper cleaning and oiling extends the lifespan of both methods, but induction stovetop seasoning typically demands less intensive maintenance for long-term cookware performance.

Flavor Development: Woodfire Aroma vs Modern Neutrality

Campfire curing imparts a rich woodfire aroma that deeply enhances the flavor profile, creating a smoky, robust taste unique to traditional methods. This natural infusion of flavor is prized for its complexity and authentic character in culinary applications.

Induction stovetop seasoning offers a modern, neutral approach to maintenance that preserves the base taste of food without overwhelming it with additional aromas. Its precise temperature control ensures even seasoning, maintaining the original flavor integrity while preventing unwanted char or bitterness.

Safety Considerations for Campfire and Induction Curing

What are the safety considerations when choosing between campfire curing and induction stovetop seasoning for maintenance? Campfire curing requires careful attention to open flames and potential fire hazards, especially in dry or windy environments where sparks can ignite surrounding materials. Induction stovetop seasoning offers a controlled heat source with minimal risk of flare-ups, making it safer for indoor use and reducing the chance of burns or accidental fires.

Related Important Terms

Carbonized layering

Campfire curing creates a thicker, uneven carbonized layer that enhances natural non-stick properties but may risk flaking, while induction stovetop seasoning produces a more uniform carbonized coating that offers consistent maintenance and durability. Regular induction stovetop seasoning ensures controlled heat application leading to a stable polymerized layer, preserving the pan's longevity and resistance to rust.

Ember-haze seasoning

Ember-haze seasoning creates a durable, non-stick barrier that excels in campfire curing by infusing cast iron with rich, smoky residues, enhancing flavor depth and rust resistance. Induction stovetop seasoning offers precise temperature control for even polymerization, maintaining cookware longevity but typically lacks the complex flavor notes achieved through campfire curing.

Induction-pulse curing

Induction-pulse curing for maintenance on induction stovetops offers precise temperature control and rapid heat cycles that enhance seasoning durability and prevent uneven polymerization common in campfire curing. This method ensures consistent seasoning layers by using electromagnetic pulses to uniformly heat cookware surfaces, reducing oxidation and extending the lifespan of the seasoning compared to traditional campfire methods.

Micro-tempering cycles

Campfire curing employs direct flame exposure creating micro-tempering cycles that enhance blade hardness through rapid thermal fluctuations, whereas induction stovetop seasoning offers controlled, consistent heat promoting even seasoning layers without stressing the metal structure. The micro-tempering cycles from campfire curing can result in localized grain refinement, improving edge retention but requiring careful monitoring to avoid overheating or warping during maintenance.

Oxidative patina shift

Campfire curing allows for a natural oxidative patina shift by exposing cookware to uneven heat and open flames, promoting a robust seasoning layer with varied polymerized oils. Induction stovetop seasoning delivers a more controlled heat environment, resulting in a uniform patina that enhances maintenance by minimizing oxidation inconsistencies.

Magneto-heat retention

Campfire curing relies on natural heat distribution and imparts smoky flavors while promoting a rustic seasoning build-up, but induction stovetop seasoning offers precise magneto-heat retention enabling uniform surface temperatures that enhance polymerized oil bonding for superior non-stick maintenance. Induction stovetop seasoning accelerates cure times and ensures consistent seasoning layers, outperforming campfire methods by providing control over heat intensity and reducing uneven seasoning or spots prone to degradation.

Biofilm flake resistance

Campfire curing creates a robust, uneven biofilm layer that enhances flake resistance by promoting natural seasoning adhesion through high heat and smoke exposure, while induction stovetop seasoning produces a more uniform, controlled polymerized oil layer that prevents biofilm flaking by forming a smoother, chemically bonded surface. Maintenance with campfire-cured surfaces requires less frequent reseasoning due to biofilm durability, whereas induction stovetop seasoning necessitates regular touch-ups to maintain optimal anti-flake protection.

Ambient smoke absorption

Campfire curing imparts a rich ambient smoke absorption to cookware, enhancing flavor depth through prolonged exposure to natural wood smoke compounds. In contrast, induction stovetop seasoning offers controlled heat for oil polymerization but lacks the penetrating smoky essence characteristic of campfire environments.

Spot-seasoning flashpoint

Campfire curing develops a natural, smoky patina by exposing cookware to open flames, enhancing flavor but risking uneven heat and potential flashpoints. Induction stovetop seasoning offers precise temperature control, reducing flashpoint risks during spot-seasoning and ensuring consistent, durable seasoning layers for cookware maintenance.

Campfire curing vs induction stovetop seasoning for maintenance. Infographic

cookingdiff.com

cookingdiff.com