Cast iron cure using traditional methods creates a durable, non-stick surface by polymerizing oils at high heat, offering long-lasting protection against rust and food sticking. Flaxseed oil cure is favored for its high concentration of polyunsaturated fats, which form a hard, smooth seasoning layer, but it may require multiple applications for optimal durability. Both methods improve pan performance, but flaxseed oil can produce a shinier finish, while conventional cast iron seasoning tends to be more forgiving and easier to maintain.

Table of Comparison

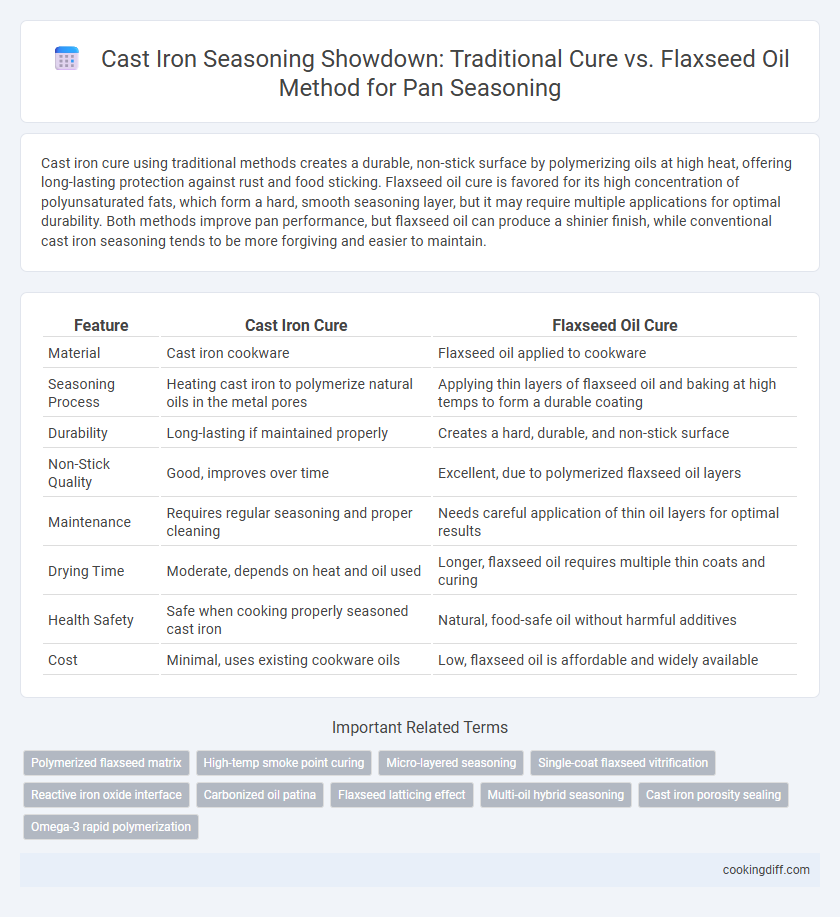

| Feature | Cast Iron Cure | Flaxseed Oil Cure |

|---|---|---|

| Material | Cast iron cookware | Flaxseed oil applied to cookware |

| Seasoning Process | Heating cast iron to polymerize natural oils in the metal pores | Applying thin layers of flaxseed oil and baking at high temps to form a durable coating |

| Durability | Long-lasting if maintained properly | Creates a hard, durable, and non-stick surface |

| Non-Stick Quality | Good, improves over time | Excellent, due to polymerized flaxseed oil layers |

| Maintenance | Requires regular seasoning and proper cleaning | Needs careful application of thin oil layers for optimal results |

| Drying Time | Moderate, depends on heat and oil used | Longer, flaxseed oil requires multiple thin coats and curing |

| Health Safety | Safe when cooking properly seasoned cast iron | Natural, food-safe oil without harmful additives |

| Cost | Minimal, uses existing cookware oils | Low, flaxseed oil is affordable and widely available |

Cast Iron Cure vs Flaxseed Oil: An Overview

Cast iron cure creates a durable, non-stick surface by polymerizing oils at high temperatures, while flaxseed oil cure forms a hard, protective layer that resists flaking. Both methods improve pan seasoning but differ in application time and longevity of the coating.

- Cast Iron Cure - Uses high heat to bond oils into a tough, non-stick seasoning layer.

- Flaxseed Oil Cure - Applies multiple thin coats of flaxseed oil that polymerize into a hard, resilient surface.

- Durability Comparison - Cast iron cure typically offers longer-lasting seasoning, whereas flaxseed oil cure may require more frequent maintenance.

What is Cast Iron Curing?

| Cast Iron Curing | Cast iron curing is the process of polymerizing oils, such as flaxseed or vegetable oil, onto the pan's surface through heat, creating a durable, non-stick coating that protects against rust. This seasoning involves applying a thin layer of oil and heating the pan to a temperature typically between 375degF and 500degF, causing the oil to bond with the cast iron. Proper curing enhances the pan's cooking performance and longevity by forming a naturally smooth and chemically resistant surface. |

Flaxseed Oil Cure: The Science Explained

Flaxseed oil cure excels in creating a durable, hard seasoning layer on cast iron pans due to its high concentration of polyunsaturated fatty acids, which undergo polymerization when heated. This chemical reaction forms a strong, smooth, and non-stick coating that enhances the pan's cooking performance and longevity.

Unlike traditional cast iron cure methods that may rely on thicker oils, flaxseed oil's drying properties contribute to a more efficient curing process with less sticky residue. Scientific studies show that flaxseed oil's molecular structure promotes a tightly bonded seasoning layer, improving resistance to flaking and rust.

Traditional Methods for Cast Iron Seasoning

Cast iron cure traditionally relies on high-heat polymerization of fats to create a durable, non-stick surface that improves with use. Flaxseed oil cure involves applying a thin layer of flaxseed oil and baking it at a high temperature, forming a hard, protective seasoning layer favored by many enthusiasts.

- High-Temperature Polymerization - Cast iron seasoning is achieved by heating fats to their smoke point, which polymerizes and bonds to the pan's surface.

- Flaxseed Oil Effectiveness - Flaxseed oil contains high levels of polyunsaturated fats ideal for creating a strong, resilient coating through multiple thin layers.

- Durability and Maintenance - Traditional cast iron cures develop over time with repeated use, while flaxseed oil seasoning may require more precise application but yields a harder finish.

Pros and Cons of Flaxseed Oil for Pan Seasoning

Flaxseed oil cures form a hard, durable layer on cast iron pans through polymerization, providing excellent non-stick properties and resistance to flaking. However, flaxseed oil is prone to becoming sticky if applied too thickly or unevenly, requiring careful application and temperature control during seasoning. Despite its drying benefits, it has a shorter shelf life and can become rancid faster compared to other oils used for pan seasoning.

Comparing Durability: Cast Iron Cure vs Flaxseed Oil Cure

Cast iron cure forms a hard, durable coating through polymerization that can withstand high heat and frequent use without degrading. Flaxseed oil cure creates a thin, somewhat fragile layer prone to chipping and requires more frequent reapplication for maintaining seasoning.

- Long-lasting Protection - Cast iron cure creates a robust, well-bonded layer resistant to wear and rust.

- Maintenance Frequency - Flaxseed oil cure often needs more constant upkeep due to its less durable film.

- Heat Tolerance - Cast iron cure withstands higher temperatures without breaking down compared to flaxseed oil.

Choosing cast iron cure enhances the pan's seasoning durability and reduces maintenance over time.

Step-by-Step Guide: Standard Cast Iron Seasoning

Standard cast iron seasoning begins by thoroughly cleaning the pan to remove any factory coatings or rust, followed by drying it completely. A thin layer of oil, typically flaxseed oil due to its polymerization properties, is applied evenly over the entire surface.

Next, the pan is heated in an oven at 450-500degF for one hour to allow the oil to bond and form a durable, non-stick layer. This step is repeated multiple times to build up a strong seasoning coating. Cast iron seasoning with flaxseed oil results in a hard, smooth finish that enhances the pan's longevity and cooking performance.

Step-by-Step Guide: Flaxseed Oil Seasoning

How do you properly season a cast iron pan using flaxseed oil? Begin by applying a thin layer of flaxseed oil evenly across the pan's surface to promote a durable, non-stick coating. Bake the pan upside down at 450degF (232degC) for one hour, then allow it to cool completely to enhance the polymerization process.

Common Pitfalls and Troubleshooting in Seasoning Methods

Cast iron cure often faces issues like uneven coating or flaking due to improper oil application or insufficient heat, while flaxseed oil cure may develop sticky residue if overheated. Common pitfalls include using too much oil or not allowing adequate polymerization time, leading to a weak seasoning layer on pans. Troubleshooting involves ensuring thin, even oil layers and baking at the correct temperature to achieve durable, non-stick seasoning surfaces.

Related Important Terms

Polymerized flaxseed matrix

Polymerized flaxseed oil forms a hard, durable seasoning layer on cast iron pans by creating a tough, cross-linked matrix resistant to flaking and wear. This matrix enhances the pan's non-stick properties and longevity compared to traditional curing methods that rely solely on cast iron's natural seasoning buildup.

High-temp smoke point curing

Cast iron seasoning cured with flaxseed oil forms a thin, hard polymerized layer due to its high concentration of polyunsaturated fats, which polymerize effectively at high temperatures but may be less durable under repeated use. In contrast, traditional cast iron cure methods using oils with higher smoke points, such as grapeseed or canola oil, provide a more stable and robust seasoning layer by enduring elevated curing temperatures without breaking down, resulting in longer-lasting non-stick surfaces.

Micro-layered seasoning

Cast iron cure creates a durable micro-layered seasoning through polymerized fats that form a hard, non-stick surface resistant to rust. Flaxseed oil cure produces a thinner, more delicate micro-layered seasoning that offers superior hardness and adherence but requires more frequent maintenance to prevent flaking.

Single-coat flaxseed vitrification

Single-coat flaxseed oil cure creates a durable, carbonized layer through polymerization, offering superior non-stick properties and resistance to flaking compared to traditional cast iron cures that rely on multiple oil layers. This vitrification process bonds at a molecular level, enhancing seasoning longevity and providing a smoother, harder surface ideal for high-heat cooking.

Reactive iron oxide interface

Cast iron cure creates a reactive iron oxide interface that enhances polymer adhesion and durability during pan seasoning, while flaxseed oil cure forms a thinner, less stable oxide layer that may compromise long-term seasoning robustness. The iron oxide interface developed through cast iron cure facilitates superior bonding with seasoning oils, resulting in a more resilient and non-stick surface.

Carbonized oil patina

Cast iron cure develops a hard, carbonized oil patina through polymerization of fats at high heat, creating a durable, non-stick surface ideal for pan seasoning. Flaxseed oil cure also forms a carbonized patina but offers a thinner, more brittle layer that requires repeated applications for optimal seasoning durability.

Flaxseed latticing effect

Flaxseed oil cure creates a durable, polymerized lattice that forms a hard, non-stick surface on cast iron pans, outperforming traditional curing methods by producing a more resilient and self-healing seasoning layer. This natural oil undergoes a drying and cross-linking process that enhances the pan's resistance to chipping and rust, ensuring long-lasting performance.

Multi-oil hybrid seasoning

Hybrid seasoning that combines cast iron cure with flaxseed oil creates a durable, non-stick surface by leveraging the polymerization properties of flaxseed oil and the robust, heat-resistant layer formed by traditional cast iron cures. This multi-oil approach enhances seasoning longevity and improves corrosion resistance compared to single-oil cures.

Cast iron porosity sealing

Cast iron cure creates a robust, polymerized layer that effectively seals the pan's porous surface, enhancing rust resistance and providing a durable non-stick coating. Unlike flaxseed oil cure, which can form a brittle layer prone to flaking, cast iron seasoning penetrates and fills micro-pores, ensuring long-lasting porosity sealing and improved pan performance.

Cast iron cure vs flaxseed oil cure for pan seasoning. Infographic

cookingdiff.com

cookingdiff.com