Smoke curing imparts traditional smoky flavors and preserves sausages by exposing them to smoke from burning wood, enhancing aroma and shelf life through antimicrobial properties. Koji smoke curing combines this smoking process with the application of koji mold, which enzymatically breaks down proteins and fats, resulting in a more complex umami flavor and improved texture. This hybrid method accelerates fermentation while maintaining preservation benefits, producing sausages with richer taste profiles and superior tenderness compared to conventional smoke curing.

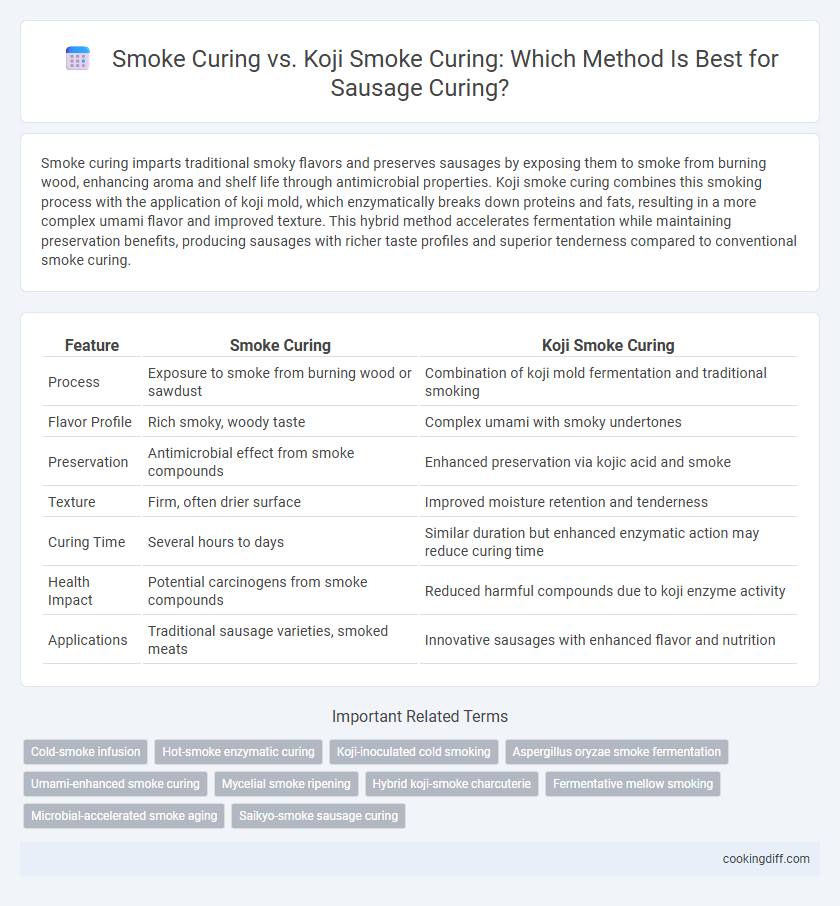

Table of Comparison

| Feature | Smoke Curing | Koji Smoke Curing |

|---|---|---|

| Process | Exposure to smoke from burning wood or sawdust | Combination of koji mold fermentation and traditional smoking |

| Flavor Profile | Rich smoky, woody taste | Complex umami with smoky undertones |

| Preservation | Antimicrobial effect from smoke compounds | Enhanced preservation via kojic acid and smoke |

| Texture | Firm, often drier surface | Improved moisture retention and tenderness |

| Curing Time | Several hours to days | Similar duration but enhanced enzymatic action may reduce curing time |

| Health Impact | Potential carcinogens from smoke compounds | Reduced harmful compounds due to koji enzyme activity |

| Applications | Traditional sausage varieties, smoked meats | Innovative sausages with enhanced flavor and nutrition |

Introduction to Smoke Curing and Koji Smoke Curing

Smoke curing is a traditional method that preserves sausages by exposing them to smoke from burning wood, which imparts flavor and inhibits bacterial growth. Koji smoke curing combines this process with the fermentation power of koji mold, enhancing umami and creating unique taste profiles.

- Smoke curing - Uses wood smoke to dry and flavor sausages while preserving them through antimicrobial compounds.

- Koji smoke curing - Incorporates Aspergillus oryzae mold fermentation to develop complex flavors alongside smoke infusion.

- Flavor impact - Koji smoke curing introduces deeper umami and tenderizes meat compared to traditional smoke curing alone.

Historical Background of Smoke Curing

Traditional smoke curing dates back thousands of years, originating as a preservation method among ancient civilizations in Northern Europe and North America. It involves exposing sausages to smoke from burning wood, which imparts flavor and antimicrobial properties.

Koji smoke curing is a more recent innovation that combines traditional smoke curing with koji mold fermentation, enhancing flavor complexity and texture. This method draws on Japanese fermentation techniques, using the enzymatic activity of Aspergillus oryzae to break down proteins and fats. It represents a fusion of ancient smoke curing with modern biochemical processes, offering a distinctive taste profile for cured sausages.

What is Koji Smoke Curing?

Koji smoke curing is an advanced method that utilizes koji mold (Aspergillus oryzae) to ferment and enhance the flavor profile of sausages during the curing process. Unlike traditional smoke curing, koji smoke curing introduces enzymes that break down proteins and fats, resulting in a more complex umami taste and improved texture. This technique combines microbial fermentation with natural smoke infusion, offering a unique and artisanal approach to sausage preservation and flavor development.

Flavor Profiles: Traditional Smoke vs. Koji Smoke

Traditional smoke curing imparts a robust, smoky flavor characterized by rich, deep wood smoke notes, which enhance the savory profile of sausages. This method often results in a slightly sweet and resinous aroma, reflecting the type of wood used during the curing process.

Koji smoke curing introduces complex umami flavors derived from the koji mold, creating a subtle sweetness and earthy undertones that complement the smoky essence. This technique also promotes enzymatic breakdown, intensifying the sausage's texture and enhancingOverall flavor depth through natural fermentation.

Impact on Texture and Appearance of Sausages

Smoke curing imparts a firm texture and a deep, smoky coloration to sausages, creating a classic rustic appearance favored in traditional charcuterie. Koji smoke curing enhances moisture retention, resulting in a softer, more tender bite while developing a subtly marbled exterior due to enzymatic activity.

Traditional smoke curing tends to produce a darker, more uniform surface with a slightly tougher casing, which can influence the sausage's slicing properties. Koji smoke curing fosters unique flavor complexity and a glossier finish, appealing to artisanal sausage makers focused on innovation and refined presentation.

Health and Safety Considerations

| Traditional smoke curing involves exposure to wood smoke, which contains polycyclic aromatic hydrocarbons (PAHs) linked to carcinogenic risks; careful control of smoke temperature and duration is essential for safety. Koji smoke curing utilizes Aspergillus oryzae fermentation, reducing reliance on direct smoke and thereby minimizing harmful PAH exposure while enhancing flavor profiles. Both methods require strict hygiene and monitoring to prevent microbial contamination, but koji smoke curing shows improved health safety by lowering toxic compound formation and promoting safer preservation. |

Technical Differences in the Curing Process

What are the technical differences between traditional smoke curing and koji smoke curing in sausage preparation? Traditional smoke curing relies on the direct application of wood smoke to impart flavor and preserve the meat through phenols and formaldehyde compounds. Koji smoke curing integrates the enzymatic action of Aspergillus oryzae mold during fermentation, enhancing umami development and accelerating protein breakdown while incorporating subtle smoky notes.

Cultural Influences in Sausage Curing Methods

Traditional smoke curing of sausages reflects deep-rooted practices in European and American cultures where wood smoke imparts distinctive flavors and preservation qualities. Koji smoke curing, influenced by Japanese fermentation techniques, introduces enzymatic activity that enhances umami and tenderizes the meat uniquely.

- European and American Smoke Curing - Utilizes hardwood smoke for flavor and antimicrobial properties, originating from centuries of preservation before refrigeration.

- Japanese Koji Fermentation - Employs Aspergillus oryzae mold spores to enzymatically enhance flavor and texture, reflecting centuries of fermented food culture.

- Cultural Fusion in Modern Sausage Curing - Combines smoke and koji methods to innovate flavor profiles while respecting traditional curing heritage.

Comparative Analysis: Pros and Cons

Smoke curing imparts a robust, traditional smoky flavor and extends shelf life through antimicrobial properties but may introduce carcinogenic compounds like polycyclic aromatic hydrocarbons. Koji smoke curing combines the enzymatic fermentation of Aspergillus oryzae with mild smoke, enhancing umami and tenderness while reducing harmful smoke elements. The koji method offers a healthier profile and complex taste but requires precise environmental control and longer processing duration compared to conventional smoke curing.

Related Important Terms

Cold-smoke infusion

Cold-smoke infusion in traditional smoke curing imparts deep smoky flavors through prolonged exposure to low-temperature smoke, whereas koji smoke curing combines enzymatic fermentation with light smoke application, enhancing umami complexity and tenderness in sausages. Koji smoke curing reduces the need for heavy smoke exposure, preserving moisture while delivering subtle smoky notes and improved flavor profiles compared to conventional cold-smoke infusion.

Hot-smoke enzymatic curing

Hot-smoke enzymatic curing, as utilized in koji smoke curing, enhances the development of complex umami flavors through controlled enzymatic reactions combined with traditional smoke infusion, resulting in a tender, richly flavored sausage. In contrast, conventional smoke curing primarily relies on smoke compounds for preservation and flavor, often lacking the depth of taste and texture achieved by the enzymatic activity present in koji smoke curing.

Koji-inoculated cold smoking

Koji-inoculated cold smoking enhances sausage curing by introducing Aspergillus oryzae enzymes that break down proteins and fats, creating complex umami flavors and improving texture compared to traditional smoke curing. This method also reduces the need for synthetic additives while preserving the meat with natural antimicrobial properties from koji fermentation.

Aspergillus oryzae smoke fermentation

Smoke curing preserves sausages by exposing them to combustion smoke, infusing phenolic compounds that inhibit microbial growth, while koji smoke curing employs Aspergillus oryzae fermentation to generate enzymes that enhance flavor complexity and accelerate enzymatic breakdown of proteins and fats. Aspergillus oryzae's metabolic activity during koji smoke fermentation contributes unique umami-rich metabolites, differentiating the cured product with improved texture and deeper aroma profiles compared to traditional smoke curing.

Umami-enhanced smoke curing

Smoke curing imparts deep smoky flavors and preserves sausages through phenolic compounds and antioxidants produced during combustion, while koji smoke curing enhances umami by integrating Aspergillus oryzae enzymes that break down proteins into savory amino acids and peptides. This combination intensifies the flavor complexity and tenderness, offering a rich umami profile beyond traditional smoke curing methods.

Mycelial smoke ripening

Mycelial smoke ripening in koji smoke curing utilizes Aspergillus oryzae to enhance flavor complexity and accelerate enzymatic breakdown of proteins and fats in sausages, resulting in a more tender texture and nuanced umami notes compared to traditional smoke curing. This biotechnological approach fosters superior preservation through controlled mycelial growth, reducing reliance on chemical preservatives while imparting distinctive aromatic profiles.

Hybrid koji-smoke charcuterie

Hybrid koji-smoke charcuterie enhances traditional sausage curing by combining enzymatic fermentation from Aspergillus oryzae with controlled smoke application, resulting in complex umami flavors and improved texture. This method accelerates proteolysis and imparts smoky phenolic compounds, distinguishing it from conventional smoke curing through deeper flavor integration and extended shelf life.

Fermentative mellow smoking

Smoke curing imparts a traditional smoky flavor and preservation through exposure to wood smoke, enhancing antimicrobial properties and shelf life in sausages. Koji smoke curing combines fermentative mellow smoking with enzymatic fermentation from Aspergillus oryzae, producing a complex umami profile and tender texture, while reducing harsh smoke compounds.

Microbial-accelerated smoke aging

Smoke curing relies on traditional combustion byproducts to inhibit microbial growth and develop flavor, while koji smoke curing utilizes Aspergillus oryzae enzymes to accelerate fermentation and enhance microbial activity, resulting in a more complex flavor profile and faster curing process. Microbial-accelerated smoke aging in koji smoke curing promotes proteolysis and lipolysis, improving texture and biogenic compound formation compared to conventional smoke curing.

Smoke curing vs koji smoke curing for curing sausages. Infographic

cookingdiff.com

cookingdiff.com