Soapstone curing enhances utensil durability by creating a naturally smooth, non-porous surface that resists sticking and does not require frequent reapplication. Carbon steel seasoning, in contrast, develops a polymerized oil layer that improves non-stick properties but demands regular maintenance to prevent rust and ensure optimal performance. Choosing between soapstone curing and carbon steel seasoning depends on desired durability, maintenance effort, and cooking style preferences.

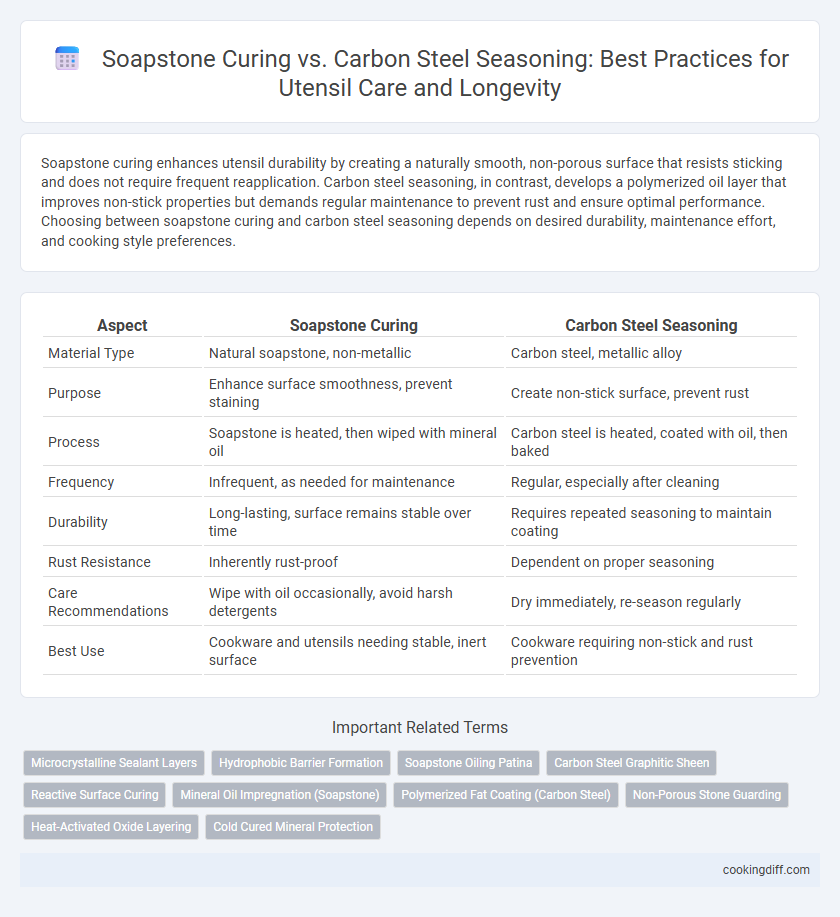

Table of Comparison

| Aspect | Soapstone Curing | Carbon Steel Seasoning |

|---|---|---|

| Material Type | Natural soapstone, non-metallic | Carbon steel, metallic alloy |

| Purpose | Enhance surface smoothness, prevent staining | Create non-stick surface, prevent rust |

| Process | Soapstone is heated, then wiped with mineral oil | Carbon steel is heated, coated with oil, then baked |

| Frequency | Infrequent, as needed for maintenance | Regular, especially after cleaning |

| Durability | Long-lasting, surface remains stable over time | Requires repeated seasoning to maintain coating |

| Rust Resistance | Inherently rust-proof | Dependent on proper seasoning |

| Care Recommendations | Wipe with oil occasionally, avoid harsh detergents | Dry immediately, re-season regularly |

| Best Use | Cookware and utensils needing stable, inert surface | Cookware requiring non-stick and rust prevention |

Introduction to Soapstone Curing and Carbon Steel Seasoning

| Soapstone Curing involves slowly heating the stone to fill its porous surface with natural oils, creating a water-resistant barrier that prevents staining and enhances durability; this process does not involve the application of synthetic coatings, making it a natural and eco-friendly method for maintaining soapstone utensils. |

| Carbon Steel Seasoning is the method of applying and polymerizing oil on the utensil's surface through controlled heating, forming a non-stick, rust-resistant patina that improves cooking performance and extends the lifespan of the steel cookware; seasoning demands regular upkeep to preserve its protective qualities. |

| The key difference lies in curing as a surface absorption and sealing technique used for soapstone, versus seasoning as a chemical transformation and layer-building process on carbon steel, each tailored to optimize the maintenance and function of their respective materials. |

What Is Soapstone Curing?

What is soapstone curing and how does it benefit utensil care? Soapstone curing involves heating the stone to harden and enhance its natural non-porous surface, improving durability and stain resistance. Unlike carbon steel seasoning, which applies a protective oil layer to prevent rust, soapstone curing relies on the stone's inherent properties to maintain a smooth, easy-to-clean finish.

What Is Carbon Steel Seasoning?

Carbon steel seasoning is the process of coating the utensil with a layer of polymerized oil to create a natural, non-stick surface and prevent rust. This method enhances the durability and cooking performance of carbon steel cookware by forming a protective barrier through repeated heating and oil applications.

- Polymerization - Applying oil and heating it causes the oil molecules to bond and form a hard, plastic-like surface on the utensil.

- Rust Prevention - The seasoned layer acts as a shield against moisture and oxygen, reducing the risk of corrosion.

- Improved Cooking - A well-seasoned carbon steel pan provides superior non-stick properties and distributes heat evenly during use.

Key Differences Between Soapstone and Carbon Steel Utensils

Soapstone curing involves simply warming the stone to remove moisture and enhance its natural non-stick surface, requiring minimal maintenance compared to carbon steel seasoning, which demands repeated oil application and heating cycles to build a protective layer against rust. Unlike carbon steel utensils that develop a patina over time, improving their cooking performance, soapstone remains chemically inert and does not react with food or oils. The key difference lies in soapstone's durability and resistance to corrosion, contrasted with carbon steel's need for ongoing care to prevent oxidation and maintain its seasoning.

Benefits of Soapstone Curing

Soapstone curing enhances the natural non-porous surface, providing superior resistance to staining and corrosion compared to carbon steel seasoning. This process requires less maintenance and eliminates the need for frequent oil applications, ensuring longer-lasting durability. Soapstone's heat retention properties improve cooking efficiency while maintaining a safe, chemical-free surface for food preparation.

Advantages of Carbon Steel Seasoning

Carbon steel seasoning develops a natural non-stick surface that improves cooking performance over time. Unlike soapstone curing, it enhances flavor retention and provides superior rust resistance for durable utensil care.

- Enhanced Non-Stick Surface - Carbon steel seasoning creates a polymerized oil layer that reduces food sticking during cooking.

- Improved Rust Protection - The seasoning layer acts as a barrier against moisture, preventing rust formation on utensils.

- Flavor Enhancement - Seasoned carbon steel absorbs and retains cooking oils, enriching the taste of dishes prepared with the utensil.

Seasoning carbon steel utensils delivers long-term usability benefits unattainable by soapstone curing methods.

Step-by-Step Guide: Curing Soapstone Utensils

Begin curing soapstone utensils by thoroughly washing them with warm water and mild soap, then allowing them to air dry completely. Apply a thin layer of mineral oil or food-safe oil over the entire surface to fill porous areas and enhance durability.

Let the oiled soapstone rest for at least 24 hours to absorb the oil completely, repeating the oil application if necessary to maintain optimal protection. Avoid exposing soapstone to extreme temperature changes to prevent cracking during curing. This method contrasts with carbon steel seasoning, which involves layering oil and heat to create a non-stick surface and prevent rust.

Step-by-Step Guide: Seasoning Carbon Steel Utensils

Seasoning carbon steel utensils involves cleaning the surface thoroughly before applying a thin layer of oil, such as flaxseed or vegetable oil, to prevent rust and create a non-stick coating. Heating the utensil gradually in an oven at around 400degF for one hour allows the oil to polymerize and bond with the metal surface.

This process should be repeated several times to build a durable seasoning layer that improves utensil performance and longevity. Unlike soapstone curing, which focuses on sealing pores naturally without heating, seasoning requires controlled heat to chemically alter the oil on the steel surface.

Maintenance Tips for Soapstone and Carbon Steel Surfaces

Soapstone requires regular cleaning with mild soap and water to maintain its natural patina and prevent buildup of oils or stains. Avoid harsh chemicals or abrasive scrubbers that can damage the stone's surface.

Carbon steel utensils benefit from proper seasoning by applying a thin layer of oil and heating to create a protective, rust-resistant coating. Store carbon steel cookware in a dry place and re-season periodically to prevent corrosion and maintain non-stick properties.

Related Important Terms

Microcrystalline Sealant Layers

Soapstone curing forms durable microcrystalline sealant layers that provide natural non-stick properties and resistance to high heat, unlike carbon steel seasoning which relies on polymerized oils creating a more fragile, organic patina. These microcrystalline layers in soapstone enhance utensil longevity by preventing rust and food adhesion without the need for repeated re-seasoning typical of carbon steel cookware.

Hydrophobic Barrier Formation

Soapstone curing creates a durable hydrophobic barrier by sealing micro-pores with natural oils, enhancing water resistance and preventing food adhesion, while carbon steel seasoning forms a polymerized oil layer through repeated heating, providing a protective non-stick surface that minimizes rust and facilitates utensil care. Both methods improve utensil longevity by reducing moisture penetration, but soapstone's mineral composition allows for a more stable and long-lasting hydrophobic effect compared to the reactive surface chemistry of carbon steel seasoning.

Soapstone Oiling Patina

Soapstone curing involves developing a natural oiling patina that enhances its resistance to moisture and staining, unlike carbon steel seasoning which relies on forming a polymerized oil layer through heating. The soapstone oiling patina not only preserves the stone's smooth surface but also deepens its color over time, providing durable protection without the risk of rust common in carbon steel utensils.

Carbon Steel Graphitic Sheen

Carbon steel seasoning develops a protective, non-stick layer through polymerized oils that enhance the utensil's durability and performance, producing a distinctive graphitic sheen that improves over time with use. Unlike soapstone curing, which relies on mineral-based treatments for surface hardening, carbon steel's seasoning process chemically bonds oil to the metal surface, preventing rust and providing superior cooking results.

Reactive Surface Curing

Soapstone curing involves natural mineral oxidation that creates a non-reactive, smooth surface ideal for cookware, enhancing durability and preventing food from sticking without requiring oil seasoning. Carbon steel seasoning develops a polymerized oil layer through high heat, forming a reactive surface that improves with use but demands regular maintenance to prevent rust and maintain non-stick properties.

Mineral Oil Impregnation (Soapstone)

Mineral oil impregnation in soapstone curing enhances the stone's durability and resistance to moisture by penetrating its porous structure, creating a protective barrier against stains and cracks. Unlike carbon steel seasoning, which forms a polymerized oil layer on the surface, soapstone's mineral oil treatment maintains natural heat retention and non-reactive properties essential for preserving flavor and utensil longevity.

Polymerized Fat Coating (Carbon Steel)

Soapstone curing involves natural mineral properties that create a durable, non-reactive surface requiring minimal maintenance, whereas carbon steel seasoning relies on creating a polymerized fat coating that forms a protective, non-stick layer through repeated oil curing and heating cycles. This polymerized fat coating chemically bonds to the steel's surface, enhancing corrosion resistance and improving cooking performance over time.

Non-Porous Stone Guarding

Soapstone curing involves sealing its naturally non-porous surface with mineral oils to enhance durability and prevent staining, ensuring long-lasting utensil protection without absorbing odors or flavors. Carbon steel seasoning creates a polymerized oil layer that forms a semi-non-porous barrier, requiring regular maintenance to prevent rust and maintain its protective properties.

Heat-Activated Oxide Layering

Soapstone curing involves the natural formation of a dense, heat-activated oxide layer that enhances utensil durability and provides a non-stick surface without additional coatings. Carbon steel seasoning relies on polymerized oils baking into a layer that forms a protective barrier, but lacks the inherent oxide robustness seen in soapstone's mineral composition.

Soapstone curing vs carbon steel seasoning for utensil care. Infographic

cookingdiff.com

cookingdiff.com