Traditional smoke curing imparts a deep, robust flavor to poultry through prolonged exposure to hardwood smoke, enhancing preservation and texture. Tea smoke curing offers a subtler, aromatic profile by using burning tea leaves, which infuses delicate notes and a unique fragrance to the meat. Both methods improve shelf life and flavor complexity, but tea smoke curing provides a lighter, more nuanced alternative to the intense smokiness of traditional techniques.

Table of Comparison

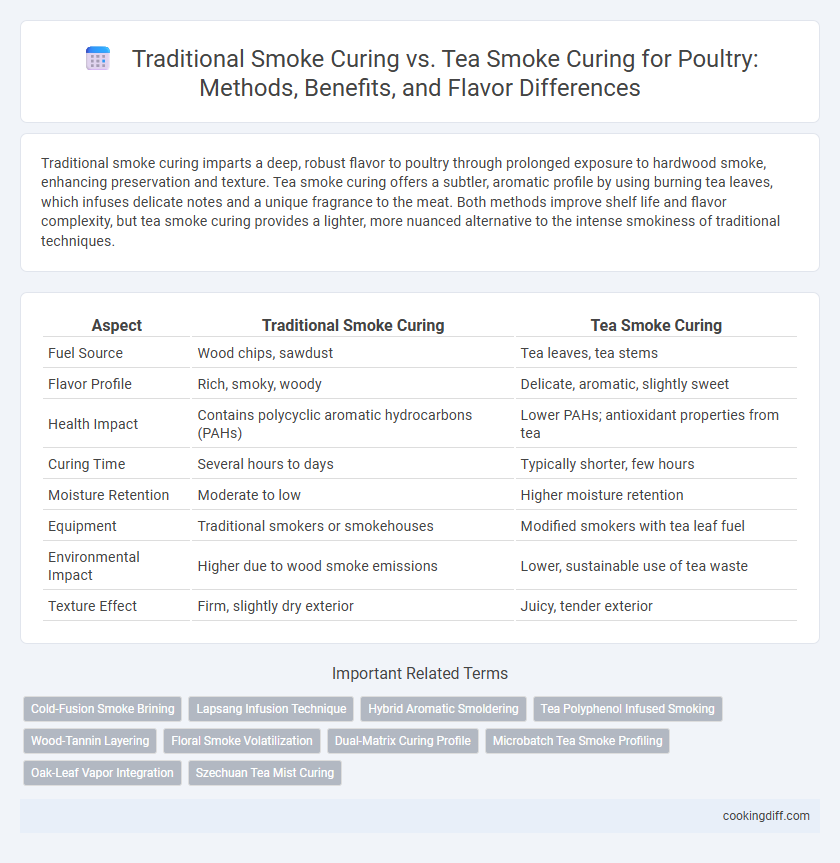

| Aspect | Traditional Smoke Curing | Tea Smoke Curing |

|---|---|---|

| Fuel Source | Wood chips, sawdust | Tea leaves, tea stems |

| Flavor Profile | Rich, smoky, woody | Delicate, aromatic, slightly sweet |

| Health Impact | Contains polycyclic aromatic hydrocarbons (PAHs) | Lower PAHs; antioxidant properties from tea |

| Curing Time | Several hours to days | Typically shorter, few hours |

| Moisture Retention | Moderate to low | Higher moisture retention |

| Equipment | Traditional smokers or smokehouses | Modified smokers with tea leaf fuel |

| Environmental Impact | Higher due to wood smoke emissions | Lower, sustainable use of tea waste |

| Texture Effect | Firm, slightly dry exterior | Juicy, tender exterior |

Overview of Smoke Curing Methods for Poultry

Traditional smoke curing imparts a robust, smoky flavor through prolonged exposure to hardwood smoke, whereas tea smoke curing uses aromatic tea leaves combined with other botanicals for a subtler, fragrant finish. Both methods enhance poultry preservation but differ significantly in flavor complexity and curing duration.

- Traditional Smoke Curing - Utilizes hardwood smoke to deeply penetrate poultry, providing strong flavor and extended shelf life.

- Tea Smoke Curing - Employs tea leaves and spices to create a delicate, aromatic smoke flavor with a shorter curing time.

- Flavor Profiles - Traditional curing tends to be intense and smoky, while tea smoke curing offers nuanced, floral notes.

What Is Traditional Smoke Curing?

Traditional smoke curing involves exposing poultry to wood smoke at low temperatures for extended periods, enhancing flavor and preservation. This method relies on natural combustion of hardwoods like hickory or oak to impart smoky aromas while inhibiting bacterial growth.

The process typically takes several hours to days, allowing the smoke to penetrate deeply into the meat. Traditional smoke curing is widely used for its rich, robust flavor and has been practiced for centuries in various cultures around the world.

The Process of Traditional Smoke Curing Poultry

How does the process of traditional smoke curing poultry work? Traditional smoke curing involves hanging poultry in a smokehouse where hardwoods like hickory or oak are burned slowly to infuse the meat with rich, smoky flavors. This method not only preserves the poultry by reducing moisture but also enhances its texture and shelf life through natural antimicrobial properties.

Introduction to Tea Smoke Curing

Tea smoke curing is an innovative method that uses fragrant tea leaves and aromatic hardwoods to infuse poultry with a unique smoky flavor while preserving its moisture. This technique contrasts with traditional smoke curing, which primarily relies on heavy wood smoke and longer exposure times.

Combining tea leaves with spices creates a delicate, fragrant aroma that enhances the poultry's natural taste without overpowering it. The shorter curing time reduces the risk of dryness common in traditional methods, resulting in tender, juicy meat. Tea smoke curing also imparts antioxidants from the tea, contributing to a healthier and more flavorful product.

How Tea Smoke Curing Works

Tea smoke curing infuses poultry with aromatic compounds released from burning tea leaves, enhancing flavor with natural antioxidants. The process involves exposing the meat to smoke generated by smoldering a mixture of tea leaves, rice, and sugar at low temperatures, which helps preserve moisture and tenderness. Compared to traditional smoke curing, tea smoke imparts a unique, subtle smoky aroma while reducing exposure to harsh chemicals and heavy smoke particulates.

Flavor Profiles: Wood Smoke vs Tea Smoke

Traditional smoke curing imparts a deep, rich wood smoke flavor to poultry, characterized by robust, savory notes that enhance the meat's natural taste. Tea smoke curing offers a lighter, more aromatic infusion, delivering subtle floral and earthy nuances that complement delicate poultry textures.

- Wood Smoke Flavor - Produces intense, smoky aromas derived from hardwoods like hickory or oak, creating a bold taste profile.

- Tea Smoke Flavor - Utilizes dried tea leaves, resulting in a gentle, fragrant smokiness with hints of herbal and floral undertones.

- Flavor Intensity - Wood smoke delivers stronger pungency while tea smoke maintains a balanced and refined flavor complexity.

Choice of curing method significantly influences the poultry's final flavor, catering to distinct culinary preferences.

Impact on Poultry Texture and Juiciness

| Traditional smoke curing imparts a dense, smoky layer to poultry, often resulting in a firmer texture as the smoke firms the meat fibers. |

| Tea smoke curing utilizes aromatic tea leaves and herbs, infusing a delicate flavor while maintaining higher moisture levels, which enhances the juiciness of the poultry. |

| The milder temperature of tea smoke curing prevents excessive drying, preserving tenderness and a more succulent mouthfeel compared to the harsher drying effect of traditional smoke curing. |

Health Considerations and Nutritional Differences

Traditional smoke curing of poultry often involves prolonged exposure to wood smoke, which can introduce polycyclic aromatic hydrocarbons (PAHs) linked to health risks such as cancer. In contrast, tea smoke curing uses tea leaves that produce fewer harmful compounds, reducing the overall toxicological impact on the meat.

Tea smoke curing preserves more nutrients, including antioxidants found in tea, which can enhance the nutritional profile of the poultry. This method also tends to retain higher protein integrity and lower sodium content compared to conventional smoke curing techniques.

Cultural and Regional Significance of Each Method

Traditional smoke curing of poultry is deeply rooted in Western and Northern European cultures, often linked to preserving meat through cold, slow smoking processes. Tea smoke curing, prominent in parts of East Asia, highlights the use of aromatic tea leaves to impart a unique flavor while reflecting local tea-growing traditions.

- Traditional Smoke Curing - Emphasizes the use of hardwoods like hickory or oak, reflecting regional forestry resources.

- Tea Smoke Curing - Utilizes tea leaves and rice to create a fragrant smoke, showcasing cultural ties to tea agriculture.

- Regional Culinary Identity - Both methods serve as culinary expressions deeply connected to their specific geographic and cultural heritage.

Related Important Terms

Cold-Fusion Smoke Brining

Cold-Fusion Smoke Brining enhances traditional smoke curing by integrating tea smoke curing techniques, using natural antioxidants from tea leaves to infuse poultry with deeper flavors while preserving moisture and tenderness. This method reduces curing time and minimizes exposure to harmful compounds found in heavy smoke, resulting in a healthier, more flavorful cold-smoked poultry product.

Lapsang Infusion Technique

Traditional smoke curing relies on prolonged exposure to wood smoke, imparting rich, smoky flavors and preserving poultry through natural antimicrobial properties. The Lapsang infusion technique enhances this process by using tea smoke from Lapsang Souchong, which infuses a distinctive piney aroma and subtle sweetness, offering a unique flavor profile and improved preservation through antioxidant compounds in the tea.

Hybrid Aromatic Smoldering

Hybrid aromatic smoldering integrates traditional smoke curing methods with tea smoke curing by combining hardwood chips and tea leaves to create a unique, flavorful environment that enhances poultry preservation and imparts complex smoky aromas. This technique optimizes the curing process by balancing heat control and aromatic infusion, resulting in tender, deeply flavored poultry with improved shelf life and distinct sensory qualities.

Tea Polyphenol Infused Smoking

Tea smoke curing infuses poultry with polyphenol-rich smoke, enhancing antioxidant properties and imparting a subtle, aromatic flavor compared to traditional smoke curing methods that rely on hardwood or charcoal. The polyphenols in tea smoke help reduce lipid oxidation in the meat, improving shelf life and offering potential health benefits by minimizing harmful compounds formed during conventional smoking.

Wood-Tannin Layering

Traditional smoke curing relies on wood smoke to penetrate poultry with phenolic compounds, enhancing flavor and preservation through natural antimicrobial tannins. Tea smoke curing substitutes wood with tea leaves, leveraging their high tannin content to create a distinct wood-tannin layering that imparts antioxidant properties and unique aromatic profiles while maintaining effective microbial inhibition.

Floral Smoke Volatilization

Traditional smoke curing of poultry relies on hardwoods that release resinous compounds with limited floral smoke volatilization, producing a robust, smoky flavor. Tea smoke curing introduces volatile floral aromatic compounds from burning tea leaves, enhancing the poultry with subtle floral notes and complex aromatic profiles while preserving moisture.

Dual-Matrix Curing Profile

Traditional smoke curing imparts a robust, uniform flavor and enhanced preservation to poultry through the penetration of phenolic compounds within a single smoke matrix. Tea smoke curing employs a dual-matrix curing profile combining aromatic tea leaves and hardwood smokes, creating a complex flavor profile and antioxidant-rich surface layer that improves moisture retention and shelf life.

Microbatch Tea Smoke Profiling

Traditional smoke curing imparts a deep, robust flavor to poultry through prolonged exposure to hardwood smoke, while Tea Smoke Curing offers a refined aroma using controlled tea leaf combustion, enhancing subtle floral and herbal notes. Microbatch tea smoke profiling allows precise modulation of smoke intensity and compound extraction, optimizing flavor complexity and preserving meat tenderness unique to small-scale artisanal curing processes.

Oak-Leaf Vapor Integration

Oak-leaf vapor integration in traditional smoke curing imparts a robust, smoky flavor and natural antimicrobial properties to poultry, enhancing preservation and taste complexity. Tea smoke curing combined with oak-leaf vapor offers a subtler, aromatic infusion that maintains moisture and tenderness while delivering a unique, mellow smoky aroma.

Traditional Smoke Curing vs Tea Smoke Curing for curing poultry. Infographic

cookingdiff.com

cookingdiff.com