Seasoned cast iron naturally develops a durable, non-stick surface through repeated heating and oil polymerization, while flaxseed oil, due to its high concentration of polyunsaturated fats, creates a hard, protective layer when polymerized properly. Flaxseed oil polymerization offers a faster build-up of seasoning but requires controlled application and curing times to prevent sticky or uneven surfaces. Both methods enhance cast iron durability and cooking performance, with flaxseed oil favored for precision seasoning and traditional seasoning valued for its robust, time-tested patina.

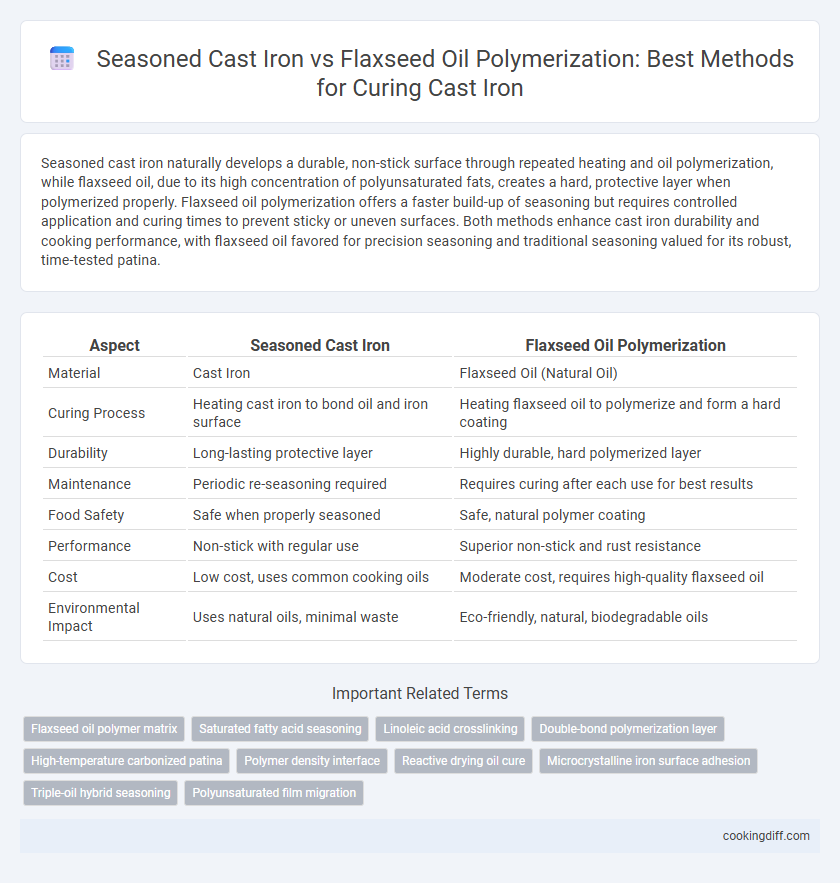

Table of Comparison

| Aspect | Seasoned Cast Iron | Flaxseed Oil Polymerization |

|---|---|---|

| Material | Cast Iron | Flaxseed Oil (Natural Oil) |

| Curing Process | Heating cast iron to bond oil and iron surface | Heating flaxseed oil to polymerize and form a hard coating |

| Durability | Long-lasting protective layer | Highly durable, hard polymerized layer |

| Maintenance | Periodic re-seasoning required | Requires curing after each use for best results |

| Food Safety | Safe when properly seasoned | Safe, natural polymer coating |

| Performance | Non-stick with regular use | Superior non-stick and rust resistance |

| Cost | Low cost, uses common cooking oils | Moderate cost, requires high-quality flaxseed oil |

| Environmental Impact | Uses natural oils, minimal waste | Eco-friendly, natural, biodegradable oils |

Introduction to Cast Iron Curing Methods

Seasoned cast iron develops a natural non-stick surface through repeated exposure to heat and cooking oils, creating a durable polymerized layer. Flaxseed oil polymerization is a popular curing method that uses high levels of unsaturated fatty acids to form a hard, protective seasoning. Both methods enhance cast iron cookware's longevity and cooking performance by preventing rust and improving surface texture.

What is Seasoned Cast Iron?

What is seasoned cast iron and how does it differ from curing with flaxseed oil polymerization? Seasoned cast iron develops a natural, non-stick surface through the polymerization of oils baked onto the cookware, typically achieved by applying vegetable shortening or lard and heating it. This built-up layer enhances rust resistance and cooking performance compared to the more modern technique of using flaxseed oil, which forms a harder, more durable coating through drying oil polymerization.

Understanding Flaxseed Oil Polymerization

Flaxseed oil polymerization is a chemical reaction where the oil undergoes oxidative cross-linking, forming a durable, hard layer on cast iron surfaces during curing. This process creates a natural, non-stick seasoning by bonding with the metal, enhancing rust resistance and cooking performance. Compared to traditional seasoned cast iron, flaxseed oil forms a more resilient, glass-like polymerized coating that improves longevity and stick resistance.

Chemical Reactions in Both Curing Techniques

| Seasoned cast iron curing involves the polymerization of fats and oils at high temperatures, forming a durable, non-stick layer through oxidation and cross-linking of triglycerides. |

| Flaxseed oil curing relies on its high content of polyunsaturated fatty acids, especially alpha-linolenic acid, which undergoes rapid oxidative polymerization creating a hard, protective film on the cast iron surface. |

| Both techniques depend on free radical formation and subsequent chemical bonding, but flaxseed oil's tri-unsaturated structure accelerates the curing process more effectively than mixed fats used in traditional seasoning. |

Durability: Seasoned Cast Iron vs Flaxseed Oil Cures

Seasoned cast iron develops a durable, natural non-stick surface through repeated heating and oil application, creating a polymerized carbon layer that resists rust and wear. This traditional method results in a tough seasoning that improves with use, enhancing the pan's longevity and cooking performance.

Flaxseed oil cures form a hard, glossy polymerized coating due to its high omega-3 content and drying properties, which can provide a durable protective layer when properly applied and baked at high temperatures. However, flaxseed oil seasoning may require multiple applications and careful maintenance to match the long-term durability of well-seasoned cast iron surfaces.

Nonstick Performance Comparison

Seasoned cast iron develops a natural nonstick surface through the buildup of polymerized fat layers formed during repeated cooking and oiling cycles. This process enhances durability and improves with regular use, providing a reliable nonstick performance for various cooking tasks.

Flaxseed oil polymerization creates a thin, hard, and smooth seasoning layer by undergoing a drying and curing process that bonds tightly to the cast iron surface. This method often results in a more uniform and potentially more resistant nonstick coating, but it requires careful application to avoid flaking or uneven seasoning.

Heat Resistance and Longevity of Each Cure

Seasoned cast iron develops a naturally robust, heat-resistant patina through repeated use and oil polymerization at moderate temperatures. Flaxseed oil creates a harder, more durable cured layer due to its high polyunsaturated fat content that polymerizes under higher heat, enhancing longevity.

- Heat Resistance of Seasoned Cast Iron - Moderate heat tolerance with a stable, non-stick surface formed from gradual oil build-up.

- Heat Resistance of Flaxseed Oil Cure - Superior heat resistance achieved by forming a tightly bonded polymerized layer at high temperatures.

- Longevity Comparison - Flaxseed oil cures typically last longer, providing extended protection and reducing the need for frequent re-seasoning compared to traditional cast iron seasoning.

Ease of Application: Traditional Seasoning vs Flaxseed Oil

Seasoned cast iron curing involves applying multiple layers of fat or oil and heating to build a durable, non-stick surface, which can require patience and practice for even coverage. Flaxseed oil polymerization creates a hard, smooth layer through the oxidation and polymerization of its high linseed oil content but demands precise temperature control and thin applications to avoid stickiness.

- Seasoned Cast Iron Ease - Traditional seasoning allows for flexible oil choices and gradual build-up but may result in uneven layers without careful technique.

- Flaxseed Oil Application - Flaxseed oil polymerizes quickly and produces a hard coating but requires thin, multiple coats baked at high temperatures for best results.

- User Convenience - Seasoning is generally more forgiving and accessible for beginners compared to the exacting process needed for flaxseed oil curing.

Choosing between seasoned cast iron and flaxseed oil curing depends on prioritizing ease of application versus achieving a hard, durable finish.

Maintenance Requirements and Best Practices

Seasoned cast iron typically requires regular maintenance involving cleaning without soap and reapplication of oil to preserve its non-stick surface and prevent rusting. Flaxseed oil polymerization offers a hard, durable seasoning but demands precise application and curing at high temperatures to avoid sticky residue and ensure optimal coating quality.

- Seasoned Cast Iron Maintenance - Clean the pan with hot water and a brush, then dry thoroughly before applying a thin layer of cooking oil to protect the surface.

- Flaxseed Oil Curing Process - Apply multiple thin coats of flaxseed oil, heat the pan in an oven at around 450degF (232degC) for an hour per coat to fully polymerize the oil.

- Best Practice for Longevity - Avoid dishwasher use and harsh detergents, and regularly re-season with appropriate oils to maintain the pan's performance and rust resistance.

Related Important Terms

Flaxseed oil polymer matrix

Flaxseed oil polymer matrix forms a durable, non-stick surface through oxidative polymerization, creating a strong, flexible layer essential for seasoning cast iron cookware. This polymerized layer resists flaking and enhances rust protection better than traditional methods, making flaxseed oil a preferred choice for achieving high-quality cast iron curing.

Saturated fatty acid seasoning

Seasoned cast iron benefits from saturated fatty acid seasoning due to its stability and resistance to oxidation during curing, enhancing non-stick properties and durability. Flaxseed oil polymerization, rich in polyunsaturated fatty acids, often leads to brittle seasoning layers prone to flaking, making saturated fat-based oils superior for long-lasting cast iron seasoning.

Linoleic acid crosslinking

Seasoned cast iron surfaces achieve durability primarily through polymerization of linoleic acid-rich oils, with flaxseed oil exhibiting superior crosslinking density due to its high polyunsaturated fatty acid content. This enhanced linoleic acid crosslinking forms a stronger, more resilient polymerized layer that improves cast iron's non-stick properties and corrosion resistance compared to traditional seasoning oils.

Double-bond polymerization layer

Seasoned cast iron curing involves developing a polymerized layer through the oxidation of fats and oils rich in double bonds, creating a durable, non-stick surface. Flaxseed oil, with its high content of polyunsaturated fatty acids, undergoes efficient double-bond polymerization, forming a hard, resilient seasoning layer superior in durability and resistance compared to other oils.

High-temperature carbonized patina

Seasoned cast iron develops a high-temperature carbonized patina through repeated polymerization of cooking oils at temperatures above 400degF, with flaxseed oil polymerization creating a harder, more durable, and smoother surface due to its high concentration of polyunsaturated fatty acids. This enhanced carbonized patina improves non-stick properties and corrosion resistance, making flaxseed oil a preferred choice for achieving a resilient, high-quality seasoning layer.

Polymer density interface

Seasoned cast iron forms a durable, dense polymer layer through repeated heating of oils, with flaxseed oil polymerization creating a highly cross-linked and dense interface that enhances non-stick properties and corrosion resistance. The superior polymer density of flaxseed oil results from its high concentration of polyunsaturated fatty acids, which promote extensive polymerization and stronger bonding on the cast iron surface.

Reactive drying oil cure

Seasoned cast iron develops a durable non-stick surface through polymerization of flaxseed oil, a reactive drying oil that undergoes oxidative cross-linking to form a hard, protective layer. This curing process enhances cast iron cookware by creating a stable, corrosion-resistant seasoning that improves with repeated use and maintenance.

Microcrystalline iron surface adhesion

Seasoned cast iron develops a durable, microcrystalline iron surface through polymerization, creating strong adhesion layers that enhance rust resistance and cooking performance. Flaxseed oil polymerizes into a hard, cross-linked film that binds effectively to the iron surface, promoting superior microcrystalline bonding compared to traditional seasoning oils.

Triple-oil hybrid seasoning

Triple-oil hybrid seasoning combines the durability of flaxseed oil polymerization with the robust seasoning layers of traditional seasoned cast iron, resulting in enhanced non-stick properties and superior rust resistance. This method leverages the rapid drying and hardening characteristics of flaxseed oil along with the established seasoning depth from multiple oils, creating a resilient, long-lasting protective coating on cast iron cookware.

Seasoned cast iron vs flaxseed oil polymerization for curing. Infographic

cookingdiff.com

cookingdiff.com