Oil curing creates a durable, non-stick skillet surface through polymerization, enhancing heat resistance and flavor retention. Flaxseed polymerization produces a hard, glossy coating by forming tightly bonded layers during heating, but requires precise temperature control to avoid uneven results. Comparing both methods, flaxseed provides a more refined finish while oil curing offers easier application and greater versatility for everyday cooking.

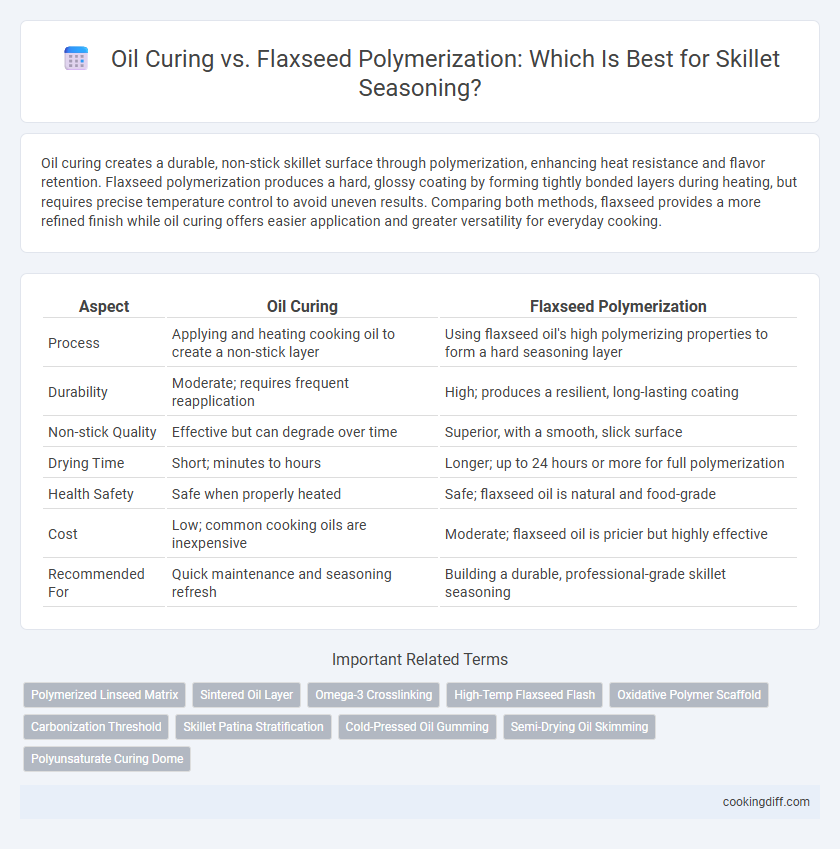

Table of Comparison

| Aspect | Oil Curing | Flaxseed Polymerization |

|---|---|---|

| Process | Applying and heating cooking oil to create a non-stick layer | Using flaxseed oil's high polymerizing properties to form a hard seasoning layer |

| Durability | Moderate; requires frequent reapplication | High; produces a resilient, long-lasting coating |

| Non-stick Quality | Effective but can degrade over time | Superior, with a smooth, slick surface |

| Drying Time | Short; minutes to hours | Longer; up to 24 hours or more for full polymerization |

| Health Safety | Safe when properly heated | Safe; flaxseed oil is natural and food-grade |

| Cost | Low; common cooking oils are inexpensive | Moderate; flaxseed oil is pricier but highly effective |

| Recommended For | Quick maintenance and seasoning refresh | Building a durable, professional-grade skillet seasoning |

Introduction to Skillet Seasoning Methods

Skillet seasoning enhances cast iron cookware's non-stick surface and protects against rust through curing oils or polymerizing flaxseed oil. Both oil curing and flaxseed polymerization involve creating a durable, baked-on layer but differ in application and chemical breakdown.

- Oil Curing - Involves heating various cooking oils to form a protective seasoning layer by polymerization and cross-linking upon exposure to heat and oxygen.

- Flaxseed Polymerization - Uses flaxseed oil with high omega-3 content that creates a harder, more durable seasoning through rapid drying and polymer formation.

- Seasoning Outcome - Flaxseed oil tends to produce a smoother, more resilient surface, while traditional oil curing may require multiple layers for optimal protection.

Choosing the seasoning method depends on desired durability, ease of application, and cooking preferences.

What Is Oil Curing?

| Oil curing is the process of seasoning a skillet by applying a thin layer of oil that undergoes polymerization when heated, creating a durable, non-stick protective coating. This method relies on the oxidation of oils such as vegetable or canola oil, which form a hard, blackened layer on the cookware surface. Unlike flaxseed polymerization, oil curing is simpler and uses commonly available cooking oils to enhance the skillet's rust resistance and improve cooking performance. |

Understanding Flaxseed Polymerization

Flaxseed polymerization involves the drying and polymerizing of linseed oil's fatty acids when exposed to heat and oxygen, creating a hard, durable layer on the skillet surface. This process forms a natural, non-stick coating that enhances seasoning longevity compared to traditional oil curing methods.

Unlike simple oil curing, flaxseed polymerization results in a more uniform and resilient seasoning due to the formation of a tightly bonded, cross-linked polymer network. This network provides superior resistance to flaking and improves the skillet's cooking performance over time.

Chemical Processes Behind Seasoning

What are the chemical differences between oil curing and flaxseed polymerization for skillet seasoning? Oil curing primarily involves the oxidation and polymerization of unsaturated fatty acids, forming a durable, non-stick layer. Flaxseed polymerization accelerates this process through a high concentration of alpha-linolenic acid, creating a harder, more resilient seasoning surface.

Comparing Oil Curing and Flaxseed Polymerization

Oil curing involves applying a thin layer of cooking oil and heating the skillet repeatedly to form a durable, non-stick surface through polymerization of the fats. Flaxseed polymerization uses flaxseed oil, which has a high concentration of polyunsaturated fatty acids, creating a harder and more resilient seasoning layer through multiple thin coats and high-heat curing. Compared to oil curing, flaxseed polymerization typically results in a smoother, more durable seasoning but requires more time and precision to avoid flaking.

Performance and Durability of Each Method

Oil curing forms a robust, polymerized layer that enhances skillet durability and provides excellent non-stick performance. Flaxseed polymerization creates a harder, more brittle seasoning layer that excels in smoothness but may require more frequent maintenance.

Performance-wise, oil curing offers consistent heat resistance and fewer flaking issues, making it ideal for everyday cooking. Flaxseed polymerization achieves a glossy finish with superior initial stick resistance, but its brittle nature can lead to cracking under heavy use. Durability depends on maintenance frequency, with oil curing favored for long-term resilience and flaxseed for a refined surface aesthetic.

Health and Safety Considerations

Oil curing for skillet seasoning often involves high-smoke-point oils like grapeseed or canola, reducing the release of harmful fumes during the process. Flaxseed polymerization emits more volatile organic compounds (VOCs), which can pose respiratory risks without proper ventilation.

Health-conscious users prefer oil curing due to its lower toxicity and reduced risk of polymer degradation byproducts. Ensuring adequate air circulation and using non-toxic oils are vital safety measures for both methods to minimize harmful exposure.

Flavor Impact on Cookware

Oil curing forms a flexible, durable seasoning layer that enhances cookware flavor without imparting strong tastes, while flaxseed polymerization creates a harder, more brittle coating that can sometimes produce a slightly nutty aroma during cooking. Both methods influence the skillet's surface interaction with food, affecting flavor retention and transfer.

- Oil curing provides a balanced seasoning - It creates a smooth, stable layer that resists strong flavor leaching, maintaining food's natural taste.

- Flaxseed polymerization imparts subtle flavor notes - The polymerized flaxseed oil can add delicate nutty undertones that subtly influence food aroma.

- Durability affects flavor impact - A more flexible oil-cured layer reduces seasoning breakdown and flavor transfer compared to brittle flaxseed coatings.

Maintenance and Re-Seasoning Tips

Oil curing creates a durable, flexible seasoning layer that withstands regular cooking and maintenance better than flaxseed polymerization. Flaxseed-based seasoning, while initially hard and glossy, tends to chip and requires more frequent re-seasoning to maintain its non-stick properties.

- Use minimal soap and avoid abrasive scrubbers - Helps preserve the integrity of both oil-cured and flaxseed-seasoned surfaces.

- Apply a thin coat of oil after each use - Promotes continuous polymerization and strengthens the seasoning layer over time.

- Re-season skillet when the surface shows dullness or unevenness - Ensures optimal non-stick performance and prevents rust formation.

Related Important Terms

Polymerized Linseed Matrix

Polymerized linseed matrix created through flaxseed oil curing forms a durable, non-stick coating on skillets by undergoing oxidative polymerization, resulting in a robust, cross-linked polymer network that enhances heat resistance and prevents rust. This natural polymerization process produces a more flexible and self-healing seasoning layer compared to traditional oil curing, which often results in brittle or uneven coatings.

Sintered Oil Layer

The sintered oil layer formed through polymerization creates a durable, non-stick surface essential for skillet seasoning, with oil curing producing a denser, more resilient coating compared to flaxseed oil polymerization. Flaxseed oil polymerization tends to form a thinner, less robust sintered layer, making oil curing preferable for long-lasting, high-performance seasoning.

Omega-3 Crosslinking

Oil curing and flaxseed polymerization differ significantly in their effectiveness for skillet seasoning due to the presence of omega-3 fatty acids in flaxseed oil, which promote superior crosslinking and form a harder, more durable seasoning layer. Omega-3 polyunsaturated fats undergo rapid oxidative polymerization, creating a tightly bonded surface that enhances the skillet's non-stick properties and longevity compared to other oils with lower omega-3 content.

High-Temp Flaxseed Flash

High-Temp Flaxseed Flash offers superior polymerization compared to traditional oil curing, creating a more durable, non-stick skillet seasoning layer resistant to peeling and cracking. This rapid curing process at elevated temperatures ensures a hard, glossy finish that enhances skillet longevity and cooking performance.

Oxidative Polymer Scaffold

Oil curing relies on oxidative polymer scaffold formation through the drying oils' exposure to oxygen, creating a durable, non-stick layer on skillets. Flaxseed polymerization produces a denser oxidative polymer scaffold with higher cross-linking, enhancing seasoning resilience and heat resistance.

Carbonization Threshold

Oil curing of skillets reaches the carbonization threshold faster due to higher heat tolerance and deeper polymer layer formation, resulting in a more durable seasoning. Flaxseed polymerization, while creating a smooth, hard finish, has a narrower temperature range before burning, making it more prone to flaking or uneven seasoning over time.

Skillet Patina Stratification

Oil curing creates a durable skillet patina through polymerized fats that build layered, non-stick surfaces while flaxseed polymerization produces a harder, brittle coating with distinct stratification. The stratification in oil-cured skillets tends to be more flexible and resilient, enhancing long-term seasoning performance compared to the delicate, flaking layers from flaxseed-based methods.

Cold-Pressed Oil Gumming

Cold-pressed oils tend to cause gumming during skillet seasoning due to incomplete polymerization, resulting in a sticky, uneven coating that impairs non-stick properties. Flaxseed oil, with its higher unsaturated fat content and faster polymerization rate, forms a durable, smooth seasoning layer, minimizing the risk of gumming and enhancing skillet performance.

Semi-Drying Oil Skimming

Semi-drying oils, like flaxseed, polymerize through oxidative cross-linking to create a durable seasoning layer on skillets, providing a hard, non-stick surface. In contrast, oil curing with non-polymerizing oils relies more on residue build-up, often resulting in a softer, less durable coating that requires frequent maintenance.

Oil Curing vs Flaxseed Polymerization for skillet seasoning. Infographic

cookingdiff.com

cookingdiff.com