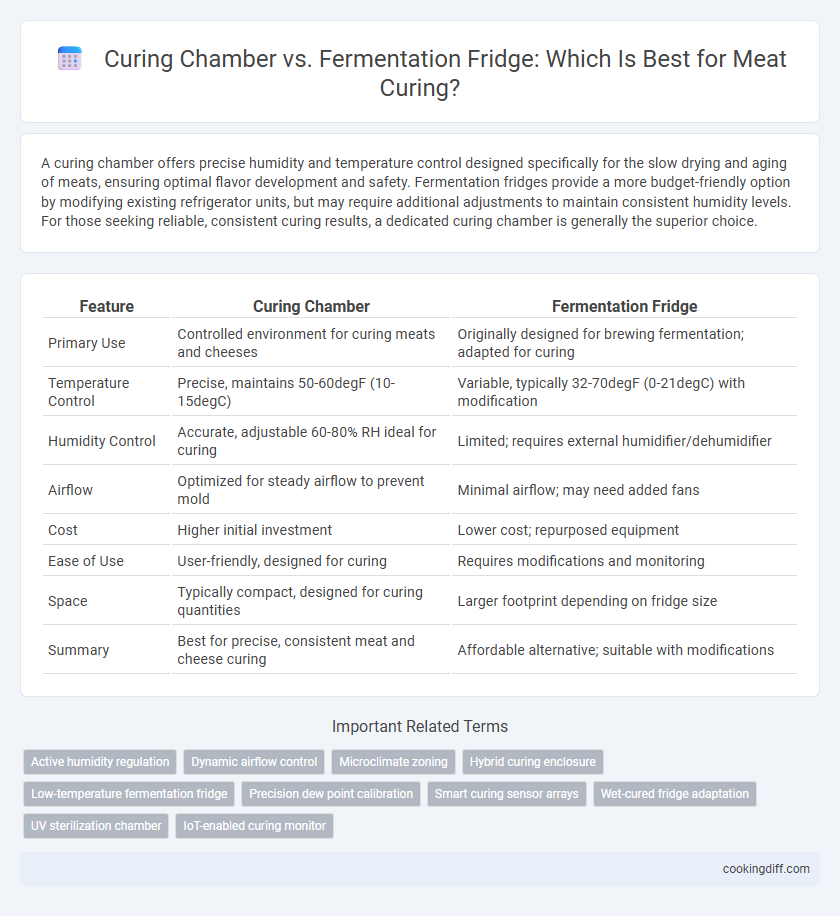

A curing chamber offers precise humidity and temperature control designed specifically for the slow drying and aging of meats, ensuring optimal flavor development and safety. Fermentation fridges provide a more budget-friendly option by modifying existing refrigerator units, but may require additional adjustments to maintain consistent humidity levels. For those seeking reliable, consistent curing results, a dedicated curing chamber is generally the superior choice.

Table of Comparison

| Feature | Curing Chamber | Fermentation Fridge |

|---|---|---|

| Primary Use | Controlled environment for curing meats and cheeses | Originally designed for brewing fermentation; adapted for curing |

| Temperature Control | Precise, maintains 50-60degF (10-15degC) | Variable, typically 32-70degF (0-21degC) with modification |

| Humidity Control | Accurate, adjustable 60-80% RH ideal for curing | Limited; requires external humidifier/dehumidifier |

| Airflow | Optimized for steady airflow to prevent mold | Minimal airflow; may need added fans |

| Cost | Higher initial investment | Lower cost; repurposed equipment |

| Ease of Use | User-friendly, designed for curing | Requires modifications and monitoring |

| Space | Typically compact, designed for curing quantities | Larger footprint depending on fridge size |

| Summary | Best for precise, consistent meat and cheese curing | Affordable alternative; suitable with modifications |

Introduction to Meat Curing: The Importance of Controlled Environments

| Controlled environments are essential for effective meat curing, ensuring precise regulation of temperature, humidity, and airflow. A curing chamber offers tailored settings specifically designed for the curing process, promoting optimal microbial growth and moisture retention. In contrast, a fermentation fridge, while adjustable, often lacks the specialized features necessary for consistent, long-term meat curing. |

What Is a Curing Chamber?

A curing chamber is a controlled environment designed to regulate temperature and humidity for the proper aging and drying of meats, cheeses, and other food products. Unlike a fermentation fridge, which primarily focuses on maintaining a constant temperature for fermenting processes, a curing chamber provides precise humidity control to prevent spoilage and promote optimal flavor development. This specialized setup is essential for safely curing charcuterie, ensuring both quality and safety throughout the maturation period.

Understanding Fermentation Fridges in Curing

Fermentation fridges provide precise temperature and humidity control essential for efficient curing processes. Unlike traditional curing chambers, these fridges can be easily adjusted to maintain stable environments conducive to both fermentation and curing.

Understanding fermentation fridges in curing involves recognizing their dual functionality, allowing them to serve as both fermenters and curing chambers. The ability to regulate temperature between 50degF to 70degF and humidity levels around 70% to 85% makes them ideal for curing meats and cheeses. Their adaptability reduces the need for separate equipment, improving space efficiency and ensuring consistent product quality.

Key Differences Between Curing Chambers and Fermentation Fridges

Curing chambers provide precise temperature and humidity control essential for drying and aging meats, while fermentation fridges primarily maintain temperature for yeast activity and dough rising. The humidity level in curing chambers is typically higher and more adjustable compared to fermentation fridges, which are designed to prevent excessive moisture.

- Humidity Control - Curing chambers allow fine-tuned humidity adjustment between 60-80% to prevent spoilage and promote proper curing.

- Temperature Range - Fermentation fridges maintain stable temperatures around 70degF optimal for yeast fermentation, whereas curing chambers operate cooler (50-60degF) for meat aging.

- Purpose and Design - Curing chambers are built to support long-term meat preservation with airflow regulation, while fermentation fridges focus on creating a stable environment for dough proofing.

Temperature and Humidity Control: Precision Compared

Curing chambers offer advanced temperature and humidity control systems specifically designed to maintain the ideal environment for meat curing, typically around 55-60degF and 70-80% humidity. Fermentation fridges, while capable of providing stable temperatures, often lack the fine-tuned humidity regulation necessary for consistent curing results. Precision in controlling both factors is critical to prevent spoilage and achieve optimal flavor development during the curing process.

Suitability for Different Types of Meats

Curing chambers provide precise control over temperature and humidity, making them ideal for curing a wide range of meats such as salami, prosciutto, and other dry-cured sausages. These conditions prevent spoilage and promote proper enzymatic activity essential for developing flavor and texture in cured meats.

Fermentation fridges are better suited for meats requiring specific temperature control but less stringent humidity levels, like certain types of fermented sausages or small-batch charcuterie. They offer less flexibility in humidity management, which can limit their effectiveness for long-term dry curing of larger cuts like whole hams.

Cost and Accessibility for Home Curers

Curing chambers provide precise temperature and humidity control essential for optimal meat curing but often come with higher upfront costs and limited availability, making them less accessible for home curers. These specialized units are typically designed specifically for curing processes, which can increase expenses and require more technical knowledge to operate effectively.

Fermentation fridges offer a more affordable and accessible option for home curers by adapting common refrigeration units with added humidity and temperature controllers. This DIY approach reduces costs and enhances availability, making it a popular choice for enthusiasts seeking controlled environments without investing in dedicated curing chambers.

Maintenance and Ease of Use

Curing chambers offer precise environmental controls but require regular cleaning and calibration to maintain optimal conditions. Fermentation fridges are generally easier to maintain with fewer mechanical parts, making them more user-friendly for beginners.

- Curing chamber maintenance - Necessitates frequent sanitation to prevent mold and bacteria buildup affecting meat quality.

- Fermentation fridge ease of use - Simple setup with minimal monitoring makes it accessible for hobbyists and small-scale curing.

- Calibration requirements - Curing chambers often need periodic sensor recalibration for accurate humidity and temperature control.

Choosing between these options depends on balancing maintenance commitment with desired curing precision.

Flavor and Texture Outcomes: Which Method Wins?

Which method produces superior flavor and texture outcomes: a curing chamber or a fermentation fridge? Curing chambers provide precise control over temperature and humidity, essential for developing complex flavors and ideal texture in cured meats. Fermentation fridges offer basic environmental control but often lack the consistent conditions needed for optimal flavor maturation and moisture retention.

Related Important Terms

Active humidity regulation

A curing chamber offers precise active humidity regulation using built-in humidifiers and dehumidifiers to maintain optimal moisture levels for meat preservation, while fermentation fridges rely primarily on passive humidity control through water pans and airflow adjustments. This active control in curing chambers ensures consistent humidity, reducing the risk of mold growth and product spoilage during the curing process.

Dynamic airflow control

Dynamic airflow control in curing chambers ensures precise humidity and temperature regulation, promoting uniform drying and preventing spoilage during the curing process. Fermentation fridges often lack this advanced airflow management, leading to inconsistent curing conditions and potential quality variations in the final product.

Microclimate zoning

A curing chamber provides precise microclimate zoning with controlled temperature, humidity, and airflow essential for uniform meat curing, whereas a fermentation fridge often lacks this level of environmental stability, risking inconsistent curing results. Advanced curing chambers utilize segmented zones to maintain optimal conditions for different dry-cured products, enhancing texture and flavor development compared to standard fermentation fridges.

Hybrid curing enclosure

A hybrid curing enclosure combines the precise humidity and temperature control of a curing chamber with the fermentation capabilities of a fridge, optimizing conditions for accelerated and consistent meat curing. This integration prevents mold growth and ensures even aging, creating an ideal environment for artisanal charcuterie production.

Low-temperature fermentation fridge

A low-temperature fermentation fridge provides consistent climate control and humidity regulation critical for optimal curing, reducing the risk of spoilage compared to traditional curing chambers. Its precision in maintaining stable temperatures between 50-60degF and humidity around 70-80% creates an ideal environment for slow curing processes, enhancing flavor development and texture in meats and cheeses.

Precision dew point calibration

A curing chamber provides superior precision dew point calibration essential for optimal moisture control during the curing process, unlike a fermentation fridge which lacks specialized humidity regulation. Accurate dew point management in curing chambers prevents mold growth and ensures consistent texture and flavor development in cured products.

Smart curing sensor arrays

Smart curing sensor arrays integrated in curing chambers provide precise real-time monitoring of temperature, humidity, and airflow, optimizing the meat aging process far beyond the capabilities of traditional fermentation fridges. These advanced sensors enable automated adjustments to environmental conditions, ensuring consistent microbial activity and preventing spoilage during extended curing periods.

Wet-cured fridge adaptation

Wet-cured fridge adaptation for curing requires precise humidity and temperature control that fermentation fridges can provide, making them suitable substitutes for dedicated curing chambers. Maintaining consistent conditions around 50-70% humidity and 50-60degF temperature is critical in wet curing processes, and fermentation fridges offer this environment efficiently with adjustable settings and compact design.

UV sterilization chamber

Curing chambers with built-in UV sterilization provide precise temperature and humidity control while actively eliminating mold spores and bacteria, ensuring safer and more consistent curing results compared to fermentation fridges. The integration of UV light enhances air quality within the curing environment, reducing contamination risks and promoting optimal preservation of flavor and aroma compounds in cured products.

Curing chamber vs fermentation fridge for curing. Infographic

cookingdiff.com

cookingdiff.com