Cheesecloth wrap allows for natural air circulation during curing, helping to develop a traditional texture and flavor, while collagen sheets provide a more uniform shape and moisture retention, resulting in a consistent product. Cheesecloth is breathable and ideal for slower drying processes, whereas collagen sheets offer convenience and reduce the risk of contamination by providing a protective barrier. Choosing between cheesecloth and collagen depends on whether you prioritize traditional curing methods or enhanced control over moisture and hygiene.

Table of Comparison

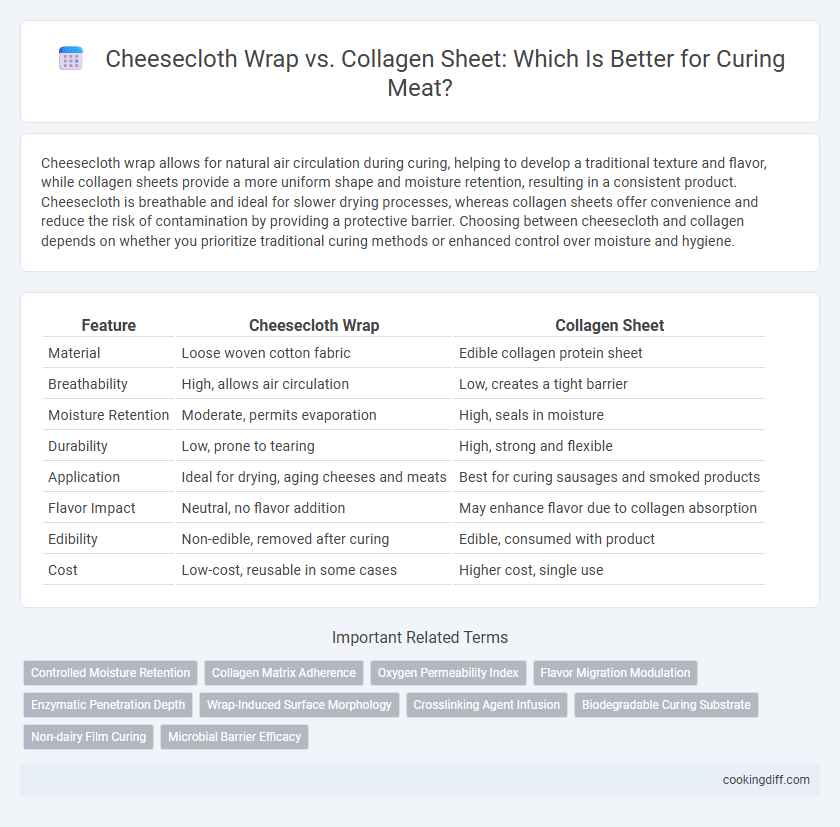

| Feature | Cheesecloth Wrap | Collagen Sheet |

|---|---|---|

| Material | Loose woven cotton fabric | Edible collagen protein sheet |

| Breathability | High, allows air circulation | Low, creates a tight barrier |

| Moisture Retention | Moderate, permits evaporation | High, seals in moisture |

| Durability | Low, prone to tearing | High, strong and flexible |

| Application | Ideal for drying, aging cheeses and meats | Best for curing sausages and smoked products |

| Flavor Impact | Neutral, no flavor addition | May enhance flavor due to collagen absorption |

| Edibility | Non-edible, removed after curing | Edible, consumed with product |

| Cost | Low-cost, reusable in some cases | Higher cost, single use |

Understanding the Basics: Cheesecloth Wrap and Collagen Sheet

Cheesecloth wrap and collagen sheets serve as essential tools in the curing process, each offering distinct properties for moisture regulation and protection. Understanding their basic characteristics helps optimize curing outcomes for meats and cheeses.

- Cheesecloth Wrap - A loosely woven cotton fabric that allows airflow and gradual drying, ideal for traditional curing methods.

- Collagen Sheet - A synthetic, edible casing that provides a uniform barrier, retaining moisture and enhancing shape consistency during curing.

- Material Properties - Cheesecloth is breathable and biodegradable, while collagen sheets offer durability and a controlled curing environment.

Choosing between cheesecloth and collagen sheets depends on the desired texture, moisture control, and curing duration for the product.

Material Composition: Cheesecloth vs Collagen Sheets

Cheesecloth is a loosely woven cotton fabric commonly used in curing to allow air circulation and moisture escape, aiding in the drying process. Collagen sheets are made from processed animal proteins, providing a uniform barrier that retains moisture while protecting the product from contaminants.

- Porosity - Cheesecloth's open weave promotes airflow, essential for proper curing and mold development.

- Moisture Retention - Collagen sheets maintain consistent moisture levels, preventing excessive drying during curing.

- Material Origin - Cheesecloth is plant-based cotton, whereas collagen sheets derive from animal collagen, influencing texture and curing outcomes.

Breathability and Moisture Control in Curing

Cheesecloth wrap offers superior breathability, allowing air to circulate freely around the curing product, which helps prevent mold growth. Its loose weave facilitates moisture evaporation, maintaining an ideal drying environment for meats and cheeses.

Collagen sheets provide a more controlled moisture barrier, reducing excess drying while still allowing some air exchange. This balance aids in developing consistent texture and flavor by retaining necessary moisture during the curing process.

Flavor Impact: Cheesecloth Wrap vs Collagen Sheet

Cheesecloth wrap allows for more air circulation during curing, enhancing the development of complex, tangy flavors through natural moisture evaporation. The porous texture encourages the growth of beneficial molds that contribute to a richer, more traditional flavor profile in cured meats.

Collagen sheets create a tighter, more uniform barrier that retains moisture, resulting in a milder, less intense flavor while preserving juiciness. This controlled environment reduces the risk of mold growth but can lead to a less pronounced savory depth compared to cheesecloth wrapping.

Ease of Use and Handling in Curing Processes

Cheesecloth wrap is highly flexible and breathable, allowing easy moisture control during curing, making it simple to handle and adjust. Collagen sheets offer a more uniform application and require less maintenance but can be less pliable when wrapping irregular shapes.

Handling cheesecloth involves regular monitoring to prevent excessive drying or moisture buildup, which can complicate the process. Collagen sheets, being more durable, reduce the risk of tearing and generally require fewer adjustments, streamlining the curing workflow. Both materials demand different techniques, but collagen sheets typically provide a more user-friendly experience for consistent curing results.

Cost Comparison: Cheesecloth vs Collagen Sheets

Which option offers a more cost-effective solution for curing: cheesecloth or collagen sheets? Cheesecloth is generally more affordable due to its simple cotton weave and widespread availability, making it a budget-friendly choice for large-scale or frequent curing projects. Collagen sheets, while pricier, provide a higher yield per unit and superior moisture control, potentially reducing waste and enhancing product quality over time.

Application Techniques for Each Material

Cheesecloth wrap allows for better air circulation during the curing process, promoting even drying and mold development. Collagen sheets offer a more controlled environment, limiting moisture loss and protecting the meat from contamination.

- Cheesecloth application - Loosely wrap the meat to allow airflow while preventing excessive drying.

- Cheesecloth maintenance - Regularly replace or wash to avoid bacterial buildup.

- Collagen sheet application - Tightly wrap around the product to create a uniform barrier that retains moisture.

Reusability and Sustainability Considerations

| Cheesecloth wrap offers high reusability as it can be washed and reused multiple times, promoting sustainability through reduced waste. Collagen sheets, while effective for uniform curing, are typically single-use and biodegradable, limiting their reusability but offering an eco-friendly option. Choosing cheesecloth supports sustainable practices by minimizing resource consumption, whereas collagen sheets provide biodegradability benefits in disposable applications. |

Ideal Cooking Scenarios for Cheesecloth and Collagen Sheets

Cheesecloth wrap is ideal for curing items that require airflow, such as herbs, sausages, and smoked meats, as its breathable fabric prevents moisture buildup and promotes even drying. Collagen sheets excel in curing sausages and charcuterie that benefit from a uniform shape and protection from contaminants, providing a natural casing that holds moisture and flavor. Both materials serve distinct purposes in curing: cheesecloth for drying and aeration, collagen sheets for structure and moisture retention.

Related Important Terms

Controlled Moisture Retention

Cheesecloth wrap allows moderate moisture permeability which aids in gradual drying but risks uneven moisture loss, while collagen sheets provide a controlled moisture barrier that maintains consistent humidity levels, enhancing uniform curing. Utilizing collagen sheets optimizes moisture retention to prevent excessive drying and mold growth, resulting in superior texture and flavor development during the curing process.

Collagen Matrix Adherence

Collagen sheets provide superior matrix adherence during curing compared to cheesecloth wraps, ensuring consistent moisture retention and enhanced flavor development in cured meats. Their uniform structure promotes even curing by maintaining close contact with the product's surface, reducing the risk of uneven drying or contamination.

Oxygen Permeability Index

Cheesecloth wraps exhibit a higher Oxygen Permeability Index, allowing more oxygen to pass through and promoting beneficial aerobic microbial growth during curing. In contrast, collagen sheets provide a lower Oxygen Permeability Index, creating a more controlled, anaerobic environment that helps retain moisture and prevents unwanted oxidation.

Flavor Migration Modulation

Cheesecloth wrap allows for greater airflow and moisture evaporation, enhancing flavor concentration but can lead to uneven flavor migration during curing. Collagen sheets provide a more uniform barrier that controls moisture and flavor diffusion, resulting in consistent flavor migration and a balanced taste profile.

Enzymatic Penetration Depth

Cheesecloth wrap allows shallower enzymatic penetration during curing, resulting in a milder and more controlled flavor development, whereas collagen sheets facilitate deeper enzymatic activity, enhancing tenderization and richer flavor profiles. The porous structure of cheesecloth restricts enzyme diffusion, while collagen sheets' denser composition promotes uniform enzymatic interaction throughout the meat.

Wrap-Induced Surface Morphology

Wrap-induced surface morphology significantly differs between cheesecloth wrap and collagen sheets during the curing process, with cheesecloth promoting increased moisture evaporation and rougher textures due to its porous structure, while collagen sheets create a smoother, more uniform surface by retaining humidity and reducing oxidation. These variations in surface morphology directly impact microbial growth and flavor development, making cheesecloth ideal for rustic, artisanal products and collagen sheets preferable for consistent, high-quality cured meats.

Crosslinking Agent Infusion

Cheesecloth wrap allows for natural airflow and moisture absorption during curing but offers limited penetration of crosslinking agents, resulting in slower infusion and less uniform texture development. Collagen sheets provide a controlled matrix that facilitates efficient crosslinking agent infusion, promoting consistent structural bonding and enhanced flavor retention throughout the cured product.

Biodegradable Curing Substrate

Cheesecloth wrap, made from natural cotton fibers, is a highly breathable and fully biodegradable curing substrate that supports moisture evaporation and flavor development during cheese and meat curing processes. In contrast, collagen sheets, derived from animal proteins, offer a semi-permeable, biodegradable option that provides a more uniform protective barrier, enhancing moisture retention and product shape while still allowing limited airflow.

Non-dairy Film Curing

Cheesecloth wrap offers a breathable, natural option ideal for moisture regulation and air circulation during non-dairy film curing, preventing unwanted mold growth while allowing surface drying. Collagen sheets provide a uniform, semi-permeable barrier that enhances moisture retention and protects delicate non-dairy films from contamination, ensuring consistent curing results in controlled environments.

Cheesecloth wrap vs collagen sheet for curing. Infographic

cookingdiff.com

cookingdiff.com