Dry cure seasoning involves rubbing salt and spices directly onto the utensil surface, drawing out moisture and creating a protective layer that enhances flavor and preserves the material. Wet curing, on the other hand, soaks the utensil in a brine solution, which helps to evenly distribute the cure and prevent drying or cracking. Choosing between dry cure and wet curing depends on the utensil type and desired preservation effect, with dry cures offering a concentrated seasoning and wet cures providing thorough moisture retention.

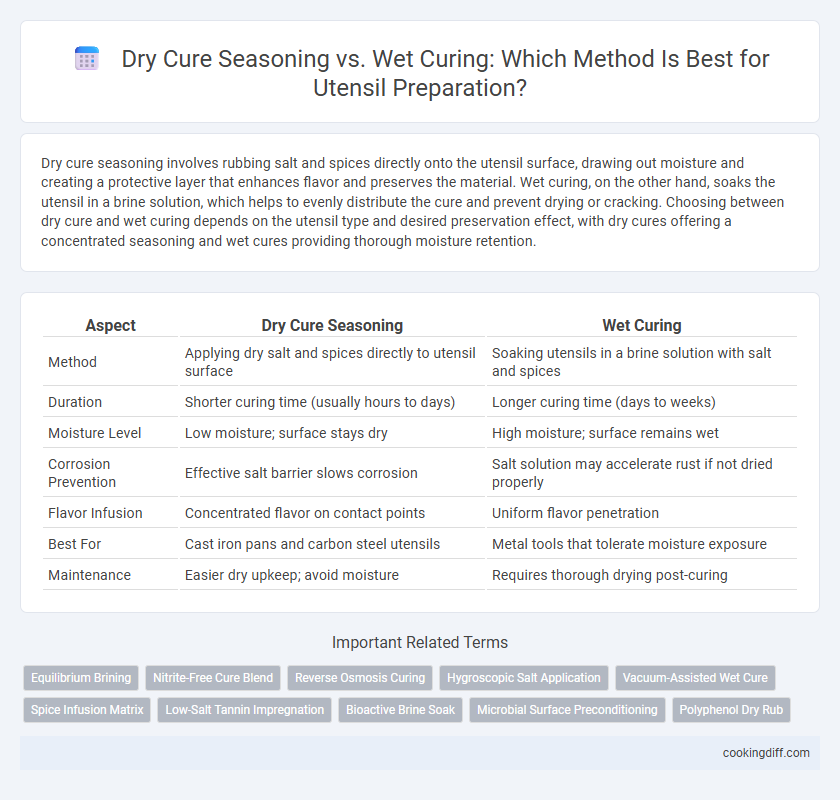

Table of Comparison

| Aspect | Dry Cure Seasoning | Wet Curing |

|---|---|---|

| Method | Applying dry salt and spices directly to utensil surface | Soaking utensils in a brine solution with salt and spices |

| Duration | Shorter curing time (usually hours to days) | Longer curing time (days to weeks) |

| Moisture Level | Low moisture; surface stays dry | High moisture; surface remains wet |

| Corrosion Prevention | Effective salt barrier slows corrosion | Salt solution may accelerate rust if not dried properly |

| Flavor Infusion | Concentrated flavor on contact points | Uniform flavor penetration |

| Best For | Cast iron pans and carbon steel utensils | Metal tools that tolerate moisture exposure |

| Maintenance | Easier dry upkeep; avoid moisture | Requires thorough drying post-curing |

Introduction to Curing Methods for Utensil Preparation

Dry cure seasoning involves rubbing salt and spices directly onto utensils to create a protective layer that enhances durability and prevents rust. This method is ideal for wooden or cast iron utensils requiring long-lasting seasoning.

Wet curing uses liquid solutions, such as brine or oil mixtures, to penetrate the utensil surface, promoting deeper seasoning and corrosion resistance. It is commonly applied to metal cookware to improve seasoning uniformity. Both dry cure and wet curing methods aim to extend utensil lifespan while enhancing performance during cooking tasks.

What is Dry Cure Seasoning?

Dry cure seasoning involves rubbing a mixture of salt, sugar, and spices directly onto the surface of utensils or cookware to enhance flavor and preservation. This method draws out moisture through osmosis, creating a concentrated seasoning layer that prevents rust and extends the life of metal tools. Dry curing is preferred for cast iron and carbon steel cookware due to its ability to maintain a natural non-stick surface without the use of liquids.

Understanding Wet Curing Techniques

Wet curing techniques involve submerging utensils in a brine solution, which enhances flavor penetration and moisture retention compared to dry cure seasoning. This method promotes uniform curing and reduces the risk of uneven seasoning buildup on cookware surfaces.

- Improved Flavor Infusion - Wet curing allows salt and spices to uniformly penetrate utensils, enhancing overall taste.

- Moisture Retention - The brine solution helps maintain optimal moisture levels, preventing utensils from drying out and cracking.

- Consistent Seasoning - Submersion in liquid ensures even curing, avoiding patchy seasoning common with dry curing.

Key Differences: Dry Cure vs Wet Cure

What are the key differences between dry cure seasoning and wet curing for utensil preparation? Dry cure seasoning involves applying a mixture of salt and spices directly to the utensil surface, promoting moisture absorption and enhanced preservation. Wet curing uses a liquid brine solution to penetrate the utensil, ensuring even seasoning and reducing the risk of uneven curing.

Flavor Impacts: Dry Cure vs Wet Cure Seasoning

Dry cure seasoning deeply penetrates utensils, enhancing flavor through salt and spice absorption, creating a robust and concentrated taste profile. Wet curing involves soaking in brine solutions, which imparts a milder, more evenly distributed flavor while maintaining moisture balance. The choice between dry cure and wet cure significantly influences the intensity and consistency of seasoning on culinary tools.

Safety Considerations in Curing Utensils

Dry cure seasoning involves applying salt and spices directly to utensils, reducing moisture that can harbor bacteria, thus enhancing food safety. This method minimizes the risk of microbial growth compared to wet curing, which uses brine solutions prone to contamination if not properly managed.

Wet curing requires strict control of temperature and sanitation to prevent pathogen proliferation during the soaking process. Ensuring utensils are thoroughly dried after wet curing is essential to avoid rust and maintain a hygienic cooking environment.

Best Utensil Types for Dry and Wet Curing

Dry cure seasoning requires non-reactive utensils like glass or ceramic to prevent oxidation, while wet curing is best suited for stainless steel or food-grade plastic containers that resist corrosion and allow easy cleaning.

- Glass and Ceramic Utensils - Ideal for dry curing due to their non-porous, inert surfaces that do not react with salt or spices.

- Stainless Steel Containers - Best for wet curing as they withstand prolonged contact with brine without corroding or imparting flavors.

- Food-Grade Plastic Bins - Convenient for wet curing, offering lightweight, easy-to-clean options that prevent metal contamination.

Select utensils that maintain flavor integrity and durability based on the curing method used.

Step-by-Step Guide to Dry Curing Utensils

Dry curing utensils involves applying a mixture of salt, sugar, and spices directly onto the surface, drawing out moisture and enhancing flavor retention. This method prevents excess liquid buildup, making it ideal for preserving metal kitchen tools and cast iron skillets.

Start by thoroughly cleaning and drying the utensil to ensure the curing mixture adheres properly. Next, coat the utensil evenly with the dry cure blend, allow it to rest for several hours, then wipe clean and reapply if necessary for thorough seasoning.

Step-by-Step Guide to Wet Curing Utensils

Wet curing utensils involves soaking in brine solutions to enhance durability and prevent rust, unlike dry cure seasoning which uses salt and oil rubs to create a protective layer. This method ensures deep penetration of moisture and salts, promoting long-lasting corrosion resistance.

- Prepare Brine Solution - Mix water, salt, and optional spices to create an effective curing liquid.

- Submerge Utensil - Fully immerse the utensil in the brine to allow thorough absorption.

- Rinse and Dry - After curing, rinse off brine and dry completely to prevent moisture retention.

Related Important Terms

Equilibrium Brining

Equilibrium brining ensures consistent salt penetration and moisture retention in both dry cure seasoning and wet curing methods by allowing the meat or utensil material to reach a balanced salt concentration without over-salting. Dry cure seasoning relies on surface salt absorption through a curing mixture, while wet curing uses a saline solution, with equilibrium brining optimizing texture and flavor stability in utensil preparation.

Nitrite-Free Cure Blend

Dry cure seasoning with nitrite-free cure blends preserves utensils by drawing out moisture and inhibiting microbial growth without chemical additives, enhancing natural flavors and extending shelf life safely. Wet curing, while effective in penetration, often relies on nitrites for preservation, which some users avoid due to potential health concerns, making nitrite-free dry curing a preferred method for eco-friendly and chemical-free utensil preparation.

Reverse Osmosis Curing

Reverse osmosis curing enhances dry cure seasoning by precisely controlling moisture levels and salt penetration, resulting in uniform flavor infusion and improved preservation without sogginess. Unlike wet curing, this method reduces water content absorption, preserving the utensil's structural integrity and extending its functional lifespan.

Hygroscopic Salt Application

Hygroscopic salt application in dry cure seasoning draws moisture out of utensils, enhancing preservation by creating a concentrated salt layer that inhibits microbial growth without diluting the surface. Wet curing, conversely, immerses utensils in brine, which can lead to uneven salt absorption and potential corrosion due to prolonged moisture exposure.

Vacuum-Assisted Wet Cure

Vacuum-assisted wet cure accelerates the infusion of brine into utensils, ensuring uniform seasoning and enhanced flavor penetration compared to traditional dry cure methods. This technique reduces curing time while maintaining moisture retention, resulting in improved texture and durability of the prepared items.

Spice Infusion Matrix

Dry cure seasoning creates a concentrated Spice Infusion Matrix by drawing moisture out, intensifying flavors directly on the utensil surface. Wet curing allows spices to penetrate deeper through brine solutions, resulting in a more uniform and enhanced aroma absorption within the material.

Low-Salt Tannin Impregnation

Dry cure seasoning with low-salt tannin impregnation enhances the utensil's durability by penetrating wood fibers more effectively than wet curing, resulting in longer-lasting protection against moisture and microbial growth. Wet curing often leads to uneven tannin absorption and higher salt residues, which can accelerate corrosion and reduce the lifespan of kitchen utensils.

Bioactive Brine Soak

Bioactive brine soak in wet curing enhances utensil preparation by deeply penetrating surfaces with antimicrobial agents, ensuring superior microbial control compared to dry cure seasoning methods. This process not only extends the lifespan of utensils but also improves hygiene by reducing the risk of bacterial contamination through sustained bioactive exposure.

Microbial Surface Preconditioning

Dry cure seasoning creates a low-moisture surface environment that inhibits microbial growth by drawing out moisture, enhancing microbial surface preconditioning by reducing bacterial colonization on utensils. Wet curing, involving brine or liquid solutions, can leave a more hydrated surface that may promote microbial activity, making dry cure seasoning more effective for microbial surface control in utensil preparation.

Dry cure seasoning vs wet curing for utensil preparation. Infographic

cookingdiff.com

cookingdiff.com