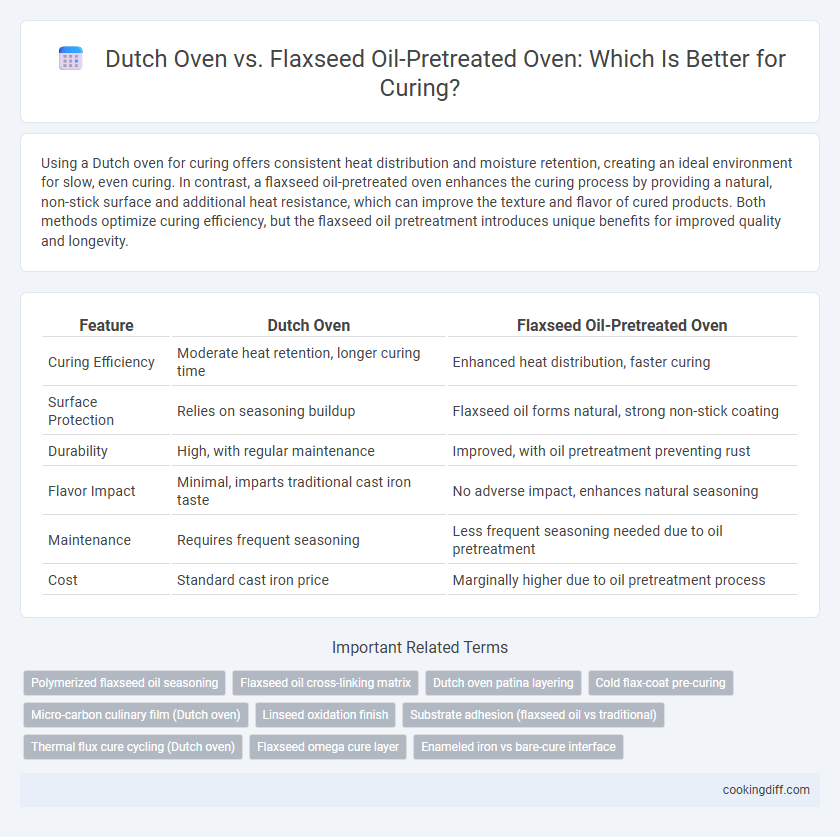

Using a Dutch oven for curing offers consistent heat distribution and moisture retention, creating an ideal environment for slow, even curing. In contrast, a flaxseed oil-pretreated oven enhances the curing process by providing a natural, non-stick surface and additional heat resistance, which can improve the texture and flavor of cured products. Both methods optimize curing efficiency, but the flaxseed oil pretreatment introduces unique benefits for improved quality and longevity.

Table of Comparison

| Feature | Dutch Oven | Flaxseed Oil-Pretreated Oven |

|---|---|---|

| Curing Efficiency | Moderate heat retention, longer curing time | Enhanced heat distribution, faster curing |

| Surface Protection | Relies on seasoning buildup | Flaxseed oil forms natural, strong non-stick coating |

| Durability | High, with regular maintenance | Improved, with oil pretreatment preventing rust |

| Flavor Impact | Minimal, imparts traditional cast iron taste | No adverse impact, enhances natural seasoning |

| Maintenance | Requires frequent seasoning | Less frequent seasoning needed due to oil pretreatment |

| Cost | Standard cast iron price | Marginally higher due to oil pretreatment process |

Introduction to Oven Curing in Cooking

What are the benefits of using a Dutch oven versus a flaxseed oil-pretreated oven for curing in cooking? A Dutch oven provides even heat distribution and retains moisture, which enhances the curing process of meats and vegetables. In contrast, a flaxseed oil-pretreated oven creates a natural non-stick surface and may improve flavor retention by preventing oxidation during curing.

What is a Dutch Oven and Its Role in Curing?

A Dutch oven is a heavy, cast-iron pot with a tight-fitting lid that retains heat evenly, making it ideal for slow-cooking and curing processes. Its ability to maintain consistent temperatures supports the curing of meats and other foods by creating a stable environment.

In curing, the Dutch oven preserves moisture and distributes heat uniformly, which helps develop flavors and texture. Compared to a flaxseed oil-pretreated oven, the Dutch oven offers superior heat retention without the risk of surface damage from oil treatments.

The Science Behind Flaxseed Oil- Pretreatment

Flaxseed oil pretreatment enhances the curing process by forming a polymerized, hydrophobic layer on the oven's surface, which improves heat retention and moisture control. This layer results from the oxidative polymerization of polyunsaturated fatty acids in flaxseed oil when exposed to high temperatures, creating a durable and non-stick coating. Compared to traditional Dutch ovens, flaxseed oil-pretreated ovens provide more consistent thermal properties that optimize the chemical reactions involved in curing meats or other foods.

Comparing Heat Distribution: Dutch Oven vs Flaxseed Oil Method

The Dutch oven provides even heat distribution through its thick cast iron walls, maintaining consistent temperatures essential for optimal curing. In contrast, the flaxseed oil-pretreated oven utilizes the oil's polymerized layer to create a non-stick surface, which slightly alters heat transfer efficiency.

While the Dutch oven evenly surrounds the food with radiant heat, ensuring uniform curing, the flaxseed oil layer can cause localized variations in temperature due to differing thermal conductivity. This may lead to uneven curing results, especially in thicker cuts or dense materials. Therefore, for precise and consistent heat distribution, the Dutch oven generally outperforms the flaxseed oil-pretreated alternative in curing applications.

Durability and Longevity of Cured Surfaces

The Dutch oven's cast iron surface provides a durable curing layer that withstands extensive use without significant wear. Flaxseed oil-pretreated ovens offer enhanced longevity through natural polymerization, creating a resilient, non-stick coating that improves with time.

- Durability of Dutch Oven - Its heavy-duty cast iron surface resists chipping and cracking, maintaining integrity through repeated heating cycles.

- Flaxseed Oil Polymerization - The oil undergoes a chemical reaction upon heating, forming a hard, protective layer that strengthens with each cure.

- Longevity of Cured Surfaces - Flaxseed oil treatments extend the life of curing surfaces by preventing rust and reducing surface degradation more effectively than untreated cast iron.

Flavor Impact: Dutch Oven vs Flaxseed Oil Cure

The Dutch oven method enhances flavor by evenly distributing heat, allowing meats to develop a rich, smoky profile through slow cooking. However, a flaxseed oil-pretreated oven introduces a subtle nutty aroma that infuses the food, elevating complexity without overpowering natural tastes.

Flaxseed oil's natural antioxidants contribute to a distinct flavor depth by reducing oxidation during curing, resulting in a fresher, more vibrant finish. In contrast, Dutch ovens maintain moisture and tenderness, which amplifies savory notes and delivers a consistently succulent texture.

Ease of Use and Maintenance

The Dutch oven offers straightforward cleaning and requires minimal upkeep due to its durable enameled surface, making it user-friendly for curing processes. In contrast, the flaxseed oil-pretreated oven demands regular reapplication of the oil to maintain its non-stick properties, increasing maintenance efforts.

- Durability - Dutch ovens resist rust and stains, reducing long-term maintenance needs.

- Surface Care - Flaxseed oil seasoning necessitates careful handling to prevent degradation.

- User Convenience - Dutch ovens provide ready-to-use convenience without frequent reconditioning.

Choosing a Dutch oven enhances ease of use and reduces maintenance time during curing.

Best Practices for Each Curing Method

| Dutch Oven | Maintain consistent low heat around 225degF to 250degF for even curing and moisture retention. |

| Flaxseed Oil-Pretreated Oven | Apply multiple thin coats of flaxseed oil, allowing full curing time between layers to create a durable, non-stick surface for optimal curing results. |

| Best Practices | Use precise temperature control and proper pre-treatment specific to the oven type to enhance flavor development and texture during curing. |

Common Mistakes to Avoid in Oven Curing

Using a Dutch oven for curing often leads to uneven heat distribution, causing inconsistent curing results and potential resin degradation. Flaxseed oil-pretreated ovens reduce sticking and improve surface quality, but failing to apply the oil evenly can result in patchy curing and contamination. Avoid overheating in both methods, as temperatures exceeding 250degF can break down active compounds and diminish the overall potency of the cured product.

Related Important Terms

Polymerized flaxseed oil seasoning

Polymerized flaxseed oil seasoning in a Dutch oven creates a durable, non-stick polymerized layer through curing that enhances heat retention and rust resistance. Pretreating the oven with flaxseed oil improves the seasoning's hardness and longevity by forming a stable, cross-linked polymer film that outperforms traditional seasoning methods.

Flaxseed oil cross-linking matrix

Flaxseed oil-pretreated ovens enhance the curing process by forming a robust cross-linking matrix that improves heat distribution and moisture retention, resulting in evenly cured materials. This molecular network accelerates polymerization and oxidation reactions, outperforming traditional Dutch ovens that lack such bio-based matrix formation.

Dutch oven patina layering

Dutch ovens develop a resilient, naturally non-stick patina through repeated seasoning and curing cycles, which enhances flavor retention and cooking performance over time. In contrast, flaxseed oil-pretreated ovens generate a smoother, harder patina layer initially but may lack the complex multi-layered seasoning that evolves in traditional Dutch oven use.

Cold flax-coat pre-curing

Cold flaxseed oil pre-curing in a Dutch oven enhances moisture retention and promotes a more uniform curing environment by creating a breathable, natural barrier that reduces oxidation and microbial growth. This method outperforms traditional Dutch oven curing by improving flavor depth and texture stability through the oil's antioxidant properties and low-temperature oil polymerization.

Micro-carbon culinary film (Dutch oven)

The Dutch oven promotes the formation of a durable micro-carbon culinary film that enhances curing by providing superior heat retention and even temperature distribution compared to flaxseed oil-pretreated ovens. This micro-carbon layer improves the seasoning process, resulting in a non-stick surface and increased durability for prolonged culinary use.

Linseed oxidation finish

Dutch ovens provide consistent heat distribution that supports uniform curing, but flaxseed oil-pretreated ovens enhance the linseed oxidation finish by promoting a more durable and protective polymerized layer. The flaxseed oil treatment accelerates oxidative cross-linking, resulting in a harder, more water-resistant cured surface compared to untreated Dutch oven curing methods.

Substrate adhesion (flaxseed oil vs traditional)

Flaxseed oil-pretreated Dutch ovens significantly enhance substrate adhesion during curing by creating a more uniform, hydrophobic surface that reduces moisture absorption and improves coating durability. In contrast, traditional Dutch ovens often suffer from uneven substrate bonding due to less effective surface preparation, leading to potential adhesion failure and compromised curing quality.

Thermal flux cure cycling (Dutch oven)

Thermal flux cure cycling in a Dutch oven ensures uniform heat distribution and controlled ramp rates, optimizing polymer cross-linking and reducing residual stresses during curing. Compared to flaxseed oil-pretreated ovens, Dutch ovens offer superior thermal stability and reproducibility, critical for consistent cure kinetics in advanced composite materials.

Flaxseed omega cure layer

Flaxseed oil-pretreated ovens develop a durable omega cure layer characterized by polymerized linolenic acid, enhancing heat retention and imparting superior non-stick and rust-resistant properties compared to traditional Dutch ovens. This natural curing method leverages flaxseed's high omega-3 fatty acid content to create a stable, bio-based protective coating that improves cookware longevity and performance.

Dutch oven vs Flaxseed oil-pretreated oven for curing. Infographic

cookingdiff.com

cookingdiff.com