Traditional meat hooks provide a reliable and straightforward method for curing by allowing air to circulate evenly around the meat, enhancing flavor and texture development. In contrast, magnetic curing rails offer a modern approach that securely holds meat in place while reducing the risk of contamination and improving hygiene during the curing process. Choosing between these options depends on the desired balance between traditional techniques and innovative efficiency in meat curing.

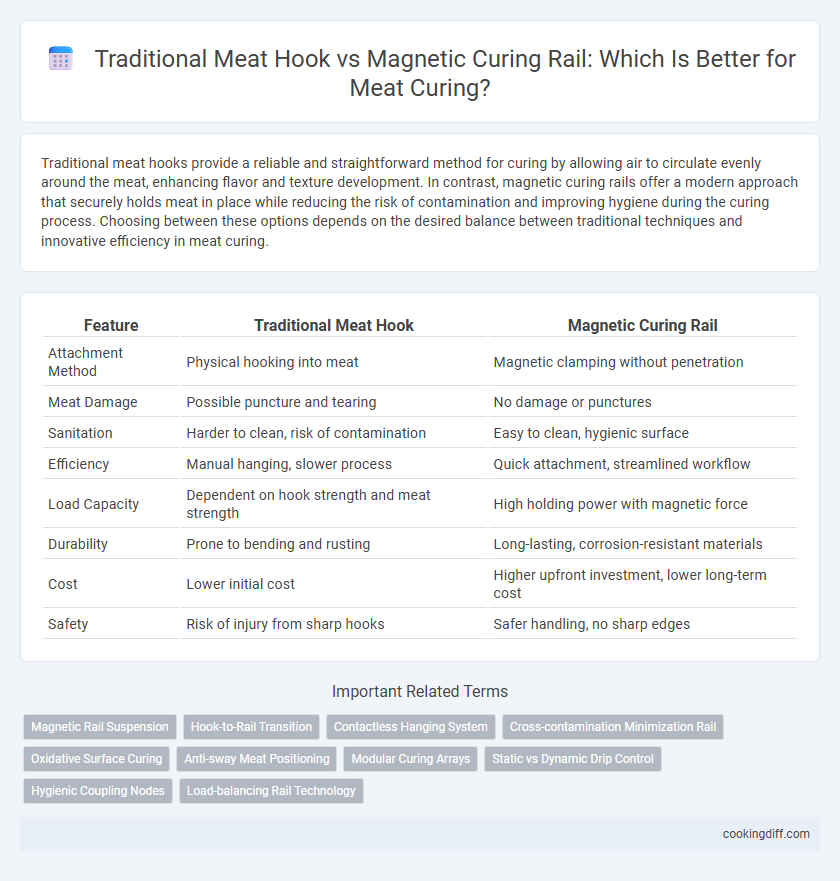

Table of Comparison

| Feature | Traditional Meat Hook | Magnetic Curing Rail |

|---|---|---|

| Attachment Method | Physical hooking into meat | Magnetic clamping without penetration |

| Meat Damage | Possible puncture and tearing | No damage or punctures |

| Sanitation | Harder to clean, risk of contamination | Easy to clean, hygienic surface |

| Efficiency | Manual hanging, slower process | Quick attachment, streamlined workflow |

| Load Capacity | Dependent on hook strength and meat strength | High holding power with magnetic force |

| Durability | Prone to bending and rusting | Long-lasting, corrosion-resistant materials |

| Cost | Lower initial cost | Higher upfront investment, lower long-term cost |

| Safety | Risk of injury from sharp hooks | Safer handling, no sharp edges |

Overview of Meat Curing Techniques

Traditional meat hooks provide a secure method for hanging meat during the curing process, allowing proper airflow and consistent drying. These hooks, often made from stainless steel or galvanized metal, are widely used in artisanal and small-scale meat curing environments.

Magnetic curing rails offer a modern alternative by securely holding meat without piercing the surface, reducing contamination risks and preserving meat quality. They enable adjustable spacing and easy cleaning, enhancing hygiene and efficiency in curing chambers. Both methods support controlled temperature and humidity conditions essential for optimal curing results.

Introduction to Traditional Meat Hooks

What are the advantages of using traditional meat hooks in the curing process? Traditional meat hooks provide reliable suspension for meats, ensuring even air circulation critical for proper curing. Their durable stainless steel construction resists corrosion and maintains strength under heavy loads, making them ideal for long-term curing environments.

Magnetic Curing Rails: A Modern Innovation

Magnetic curing rails represent a modern innovation in the meat curing process, offering enhanced sanitation and efficiency compared to traditional meat hooks. These rails reduce contamination risks by eliminating direct contact between the meat and metal surfaces, ensuring a cleaner curing environment.

Designed for easy installation and maintenance, magnetic curing rails support uniform airflow and consistent curing conditions, optimizing product quality. Their durability and ergonomic design make them a preferred choice in contemporary meat processing facilities focused on hygiene and productivity.

Material and Durability Comparison

Traditional meat hooks are typically made from stainless steel, offering strong resistance to corrosion but requiring manual handling that may wear the material over time. Magnetic curing rails use high-grade aluminum frames with embedded magnets, providing durability with less physical contact and reducing metal fatigue.

- Material Composition - Traditional hooks mainly use stainless steel, known for strength and rust resistance.

- Durability - Magnetic rails benefit from aluminum's lightweight and corrosion-resistant properties.

- Wear and Tear - Meat hooks experience more abrasion from handling, while magnetic rails minimize surface damage.

Magnetic curing rails generally offer longer lifespan and enhanced sanitation compared to traditional meat hooks due to their innovative material design and reduced physical wear.

Ease of Use: Traditional Hooks vs Magnetic Rails

Magnetic curing rails simplify the hanging process by allowing quick attachment and repositioning of meat without the need for tying or handling hooks. Traditional meat hooks require manual hooking and securing, which can be time-consuming and less adaptable in tight curing rooms.

- Magnetic rails offer tool-free usage - They enable quick attachment and adjustment of meat pieces through magnetic force, reducing labor effort.

- Traditional hooks involve manual handling - These require physically hooking and securing meat, which can slow down setup and adjustments.

- Magnetic systems improve space efficiency - Rails allow closer hanging arrangements without risk of cross-contamination or damage from hooks.

Impact on Meat Quality and Flavor

Traditional meat hooks allow for natural air circulation around the meat, which enhances flavor development through consistent drying and aging. Magnetic curing rails provide uniform pressure distribution, reducing bruising and enabling a more even curing process that preserves texture and moisture. Studies indicate that magnetic rails can improve meat tenderness and maintain juiciness better than conventional hooks, positively impacting overall quality.

Safety and Hygiene Considerations

| Traditional Meat Hook | Risk of contamination through direct metal contact and difficult sanitization; potential for physical injury during handling. |

| Magnetic Curing Rail | Non-contact hanging reduces cross-contamination; easy to clean surfaces enhance hygiene; minimizes injury risks by eliminating sharp hooks. |

Efficiency in Curing Process

Traditional meat hooks provide a reliable method for hanging meat during curing but can limit airflow and slow the curing process due to restricted spacing. Magnetic curing rails optimize efficiency by allowing adjustable spacing and better air circulation, promoting even curing and reducing drying time.

Magnetic rails also enable quick repositioning of meat cuts without puncturing, preserving product integrity and enhancing sanitation. This technology improves overall workflow efficiency in curing rooms by supporting faster batch turnover and consistent results.

Cost Analysis: Investment and Maintenance

Traditional meat hooks typically require lower initial investment but incur higher maintenance costs due to rusting and frequent replacements. Magnetic curing rails involve higher upfront expenses but offer reduced maintenance as they resist corrosion and provide longer durability. Over time, magnetic curing rails can lead to cost savings through decreased downtime and less frequent part replacements.

Related Important Terms

Magnetic Rail Suspension

Magnetic curing rails offer enhanced hygiene and efficiency in meat processing by eliminating the need for physical hooks, reducing contamination risks and accelerating handling time. This innovative suspension technology ensures even weight distribution, improving curing consistency compared to traditional meat hooks that can cause stress points on the meat.

Hook-to-Rail Transition

Traditional meat hooks rely on manual placement and spacing during the curing process, often causing uneven air circulation and inconsistent curing, whereas magnetic curing rails streamline hook-to-rail transitions with adjustable positions that optimize airflow and maintain uniform curing conditions. Magnetic rails enhance efficiency by securely holding hooks in place, reducing labor time and minimizing the risk of contamination compared to conventional hook systems.

Contactless Hanging System

Magnetic curing rails offer a contactless hanging system that reduces contamination risks and improves airflow around meat, enhancing the curing process compared to traditional meat hooks that require direct contact and can harbor bacteria. This advanced system promotes uniform curing and simplifies sanitation, making it a superior choice for modern meat preservation.

Cross-contamination Minimization Rail

Magnetic curing rails significantly reduce the risk of cross-contamination by suspending meat without direct contact, unlike traditional meat hooks that can harbor bacteria in crevices. This advanced design enhances food safety and hygiene during the curing process, promoting a cleaner environment.

Oxidative Surface Curing

Traditional meat hooks expose meat surfaces directly to air, increasing oxidative reactions and potentially compromising flavor and color during curing, while magnetic curing rails create a controlled environment that minimizes oxidation by reducing air contact and enhancing uniform curing. Magnetic rails improve oxidative surface curing by maintaining humidity and temperature stability, resulting in better preservation of meat quality and extended shelf life.

Anti-sway Meat Positioning

Traditional meat hooks often allow meat to sway during curing, potentially causing uneven salt penetration and inconsistent texture development. Magnetic curing rails provide stable, anti-sway meat positioning, enhancing uniform curing by minimizing movement and ensuring consistent contact with curing agents.

Modular Curing Arrays

Traditional meat hooks offer simple suspension but lack flexibility, whereas magnetic curing rails enable modular curing arrays that optimize space and improve airflow consistency for enhanced meat preservation. Magnetic rails provide precise hook placement, allowing efficient organization and scalability in curing chambers.

Static vs Dynamic Drip Control

Traditional meat hooks offer static drip control by suspending meat in fixed positions, which can lead to uneven curing and moisture accumulation. Magnetic curing rails provide dynamic drip control through adjustable positioning and movement, enhancing air circulation and promoting consistent curing throughout the process.

Hygienic Coupling Nodes

Traditional meat hooks often use metal coupling nodes that can harbor bacteria and require frequent manual cleaning, increasing the risk of contamination during curing. Magnetic curing rails feature hygienic coupling nodes designed for easy disassembly and thoroughly sanitized surfaces, significantly enhancing food safety and reducing cross-contamination.

Traditional Meat Hook vs Magnetic Curing Rail for Curing. Infographic

cookingdiff.com

cookingdiff.com