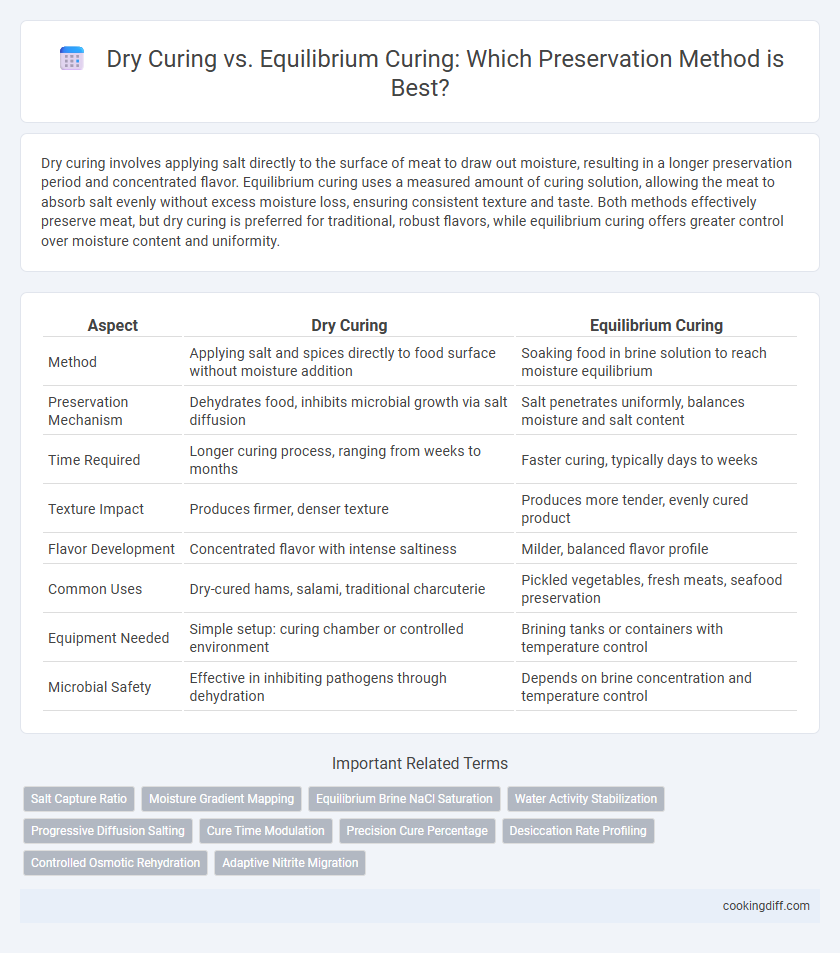

Dry curing involves applying salt directly to the surface of meat to draw out moisture, resulting in a longer preservation period and concentrated flavor. Equilibrium curing uses a measured amount of curing solution, allowing the meat to absorb salt evenly without excess moisture loss, ensuring consistent texture and taste. Both methods effectively preserve meat, but dry curing is preferred for traditional, robust flavors, while equilibrium curing offers greater control over moisture content and uniformity.

Table of Comparison

| Aspect | Dry Curing | Equilibrium Curing |

|---|---|---|

| Method | Applying salt and spices directly to food surface without moisture addition | Soaking food in brine solution to reach moisture equilibrium |

| Preservation Mechanism | Dehydrates food, inhibits microbial growth via salt diffusion | Salt penetrates uniformly, balances moisture and salt content |

| Time Required | Longer curing process, ranging from weeks to months | Faster curing, typically days to weeks |

| Texture Impact | Produces firmer, denser texture | Produces more tender, evenly cured product |

| Flavor Development | Concentrated flavor with intense saltiness | Milder, balanced flavor profile |

| Common Uses | Dry-cured hams, salami, traditional charcuterie | Pickled vegetables, fresh meats, seafood preservation |

| Equipment Needed | Simple setup: curing chamber or controlled environment | Brining tanks or containers with temperature control |

| Microbial Safety | Effective in inhibiting pathogens through dehydration | Depends on brine concentration and temperature control |

Introduction to Curing Methods

Dry curing and equilibrium curing are primary methods used in meat preservation, each affecting flavor development and moisture retention differently. Dry curing involves applying salt directly to the meat surface, while equilibrium curing uses a brine to evenly distribute curing agents throughout the product.

- Dry Curing - Salt and curing agents are rubbed onto the meat, promoting dehydration and surface preservation.

- Equilibrium Curing - Meat is soaked in a brine until the curing agents reach balance within the tissue, ensuring uniform flavor and moisture.

- Flavor Impact - Dry curing tends to produce more intense flavors due to slower moisture loss, while equilibrium curing yields a milder, consistent taste.

Both methods are essential for achieving desired texture and shelf-life in cured meat products.

What Is Dry Curing?

Dry curing is a traditional meat preservation technique that involves rubbing the meat with a mixture of salt, sugar, and spices to draw out moisture and inhibit bacterial growth. This method differs from equilibrium curing, which uses a brine solution to achieve a balanced absorption of curing agents. Dry curing enhances flavor development and produces a firmer texture, making it ideal for products like prosciutto and pancetta.

Understanding Equilibrium Curing

Equilibrium curing ensures consistent moisture content by balancing salt penetration and water loss, preserving texture and flavor longer than dry curing. This method relies on controlling environmental conditions to achieve an optimal equilibrium state between the meat and curing agents.

- Salt Diffusion Control - Equilibrium curing carefully manages salt diffusion to prevent over-curing and maintain desirable taste and safety.

- Moisture Balance - The process stabilizes moisture levels within the meat to reduce spoilage and enhance preservation quality.

- Environmental Regulation - Temperature and humidity are tightly controlled to achieve a uniform cure throughout the product.

Key Differences Between Dry Curing and Equilibrium Curing

| Aspect | Dry Curing | Equilibrium Curing |

|---|---|---|

| Method | Application of dry salt mixture directly on the meat surface. | Meat is immersed in a brine solution and cured until salt concentration equilibrates within the tissue. |

| Duration | Typically longer curing times, ranging from weeks to months. | Shorter curing times, often completed within days to weeks. |

| Salt Penetration | Slower and more uneven salt distribution, often resulting in harder outer layers. | More uniform salt diffusion throughout the meat due to liquid contact. |

| Moisture Retention | Usually lower moisture retention due to dehydration by salt. | Higher moisture retention prevents excessive drying by maintaining equilibrium. |

| Flavor and Texture | Deeper complexity of flavor with firmer texture and distinct crust development. | Milder flavor profile with tender, juicier texture. |

Salt Ratios and Measurement Accuracy

Dry curing requires precise salt ratios, often between 2% to 3% of the meat's weight, ensuring effective preservation without over-salting. Measurement accuracy in dry curing is critical, as even slight deviations can lead to spoilage or altered flavor profiles.

Equilibrium curing uses a calculated salt ratio based on the equilibrium moisture content, providing consistent curing by balancing salt diffusion and meat hydration. Accurate measurement tools and techniques are essential in equilibrium curing to maintain the steady-state salt concentration, preventing uneven preservation.

Safety Considerations in Meat Preservation

Dry curing involves applying salt directly to the meat surface, creating a hostile environment for bacterial growth, while equilibrium curing uses a brine to evenly penetrate the meat, maintaining consistent preservation. Both methods require precise control of temperature and humidity to prevent pathogen proliferation and ensure food safety.

- Salt concentration control - Prevents growth of Clostridium botulinum and other pathogens by maintaining sufficient curing agent levels.

- Temperature regulation - Critical in both methods to inhibit microbial activity and ensure safe curing conditions.

- Moisture management - Controls water activity, minimizing spoilage risk and enhancing meat preservation safety.

Flavor Development in Curing Processes

Dry curing infuses meat with intense, concentrated flavors due to slow moisture loss and salt penetration. Equilibrium curing uses brine injection or soaking, balancing flavor development with moisture retention for a milder taste.

Flavor development in dry curing intensifies through enzymatic activity and gradual dehydration, creating complex, savory profiles common in artisanal hams and salamis. Equilibrium curing controls salt distribution evenly, preventing over-salting while preserving juiciness, ideal for large-scale production of hams and bacons. Both methods rely on precise temperature and humidity control to optimize enzyme reactions responsible for flavor enhancement during curing.

Equipment and Tools for Each Method

Dry curing requires specialized equipment such as curing chambers with precise humidity and temperature controls, alongside curing racks that facilitate air circulation around the meat. Tools like salt applicators and hygrometers are essential for maintaining the correct salt concentration and monitoring environmental conditions.

Equilibrium curing often uses vacuum tumblers and vacuum-sealed bags to ensure even distribution of curing agents and accelerate the curing process. Equipment such as injection guns and automated brine mixers are vital for injecting or applying the curing solution uniformly throughout the product.

Common Mistakes and How to Avoid Them

What are common mistakes to avoid when choosing between dry curing and equilibrium curing for meat preservation? Dry curing often leads to uneven salt distribution if not carefully monitored, causing spoilage or inconsistent texture. Equilibrium curing requires precise control of temperature and time to prevent microbial growth and ensure thorough preservation.

Related Important Terms

Salt Capture Ratio

Dry curing and equilibrium curing differ significantly in salt capture ratio, a critical factor in preservation effectiveness. Dry curing typically exhibits a higher salt capture ratio, enabling more efficient salt absorption into the meat compared to equilibrium curing, which relies on a balanced salt concentration and often results in slower salt uptake.

Moisture Gradient Mapping

Dry curing creates a steep moisture gradient that slows microbial growth by drawing out water unevenly, while equilibrium curing maintains a balanced moisture gradient for consistent preservation. Moisture Gradient Mapping is essential to monitor these differences, ensuring optimal texture and shelf-life in cured products.

Equilibrium Brine NaCl Saturation

Equilibrium brine curing maintains a precise NaCl saturation level that balances salt concentration inside and outside the meat, preventing excessive moisture loss and ensuring even preservation. Dry curing relies on direct salt application, which can cause uneven salt diffusion and dehydration, whereas equilibrium brine offers controlled osmotic balance for optimal texture and flavor retention.

Water Activity Stabilization

Dry curing reduces water activity in meat by gradually removing moisture through salt absorption, leading to a stable environment that inhibits microbial growth. Equilibrium curing maintains water activity by balancing salt diffusion and moisture retention, ensuring consistent preservation without excessive dehydration.

Progressive Diffusion Salting

Dry curing uses a progressive diffusion salting method where salt gradually penetrates the meat, enhancing flavor development and moisture retention over time. Equilibrium curing relies on balancing salt concentration throughout the product, often resulting in faster preservation but less intense flavor compared to the slow, controlled salt diffusion in dry curing.

Cure Time Modulation

Dry curing involves applying salt directly to meat surfaces, resulting in slower cure time modulation and a more intense flavor development through gradual moisture loss. Equilibrium curing uses a brine solution with controlled salt concentration, allowing precise cure time modulation by balancing salt diffusion and moisture retention for uniform preservation.

Precision Cure Percentage

Dry curing achieves a higher precision cure percentage by applying a controlled amount of salt directly onto the meat surface, ensuring consistent moisture reduction and flavor development. Equilibrium curing, in contrast, relies on osmotic balance within the curing solution, often resulting in less predictable cure percentages due to variable diffusion rates.

Desiccation Rate Profiling

Dry curing relies on surface application of salt and seasonings to draw moisture gradually from meats, creating a desiccation rate profile that slows water loss and enhances flavor penetration. Equilibrium curing achieves uniform moisture reduction by submerging products in curing solutions, establishing a balanced desiccation rate that prevents uneven drying and microbial growth.

Controlled Osmotic Rehydration

Dry curing involves applying salt directly to the surface of the meat, enhancing preservation by reducing moisture content and inhibiting microbial growth, while equilibrium curing utilizes controlled osmotic rehydration to achieve uniform salt distribution, ensuring consistent preservation and texture throughout the product. Controlled osmotic rehydration in equilibrium curing balances water activity and salt penetration, optimizing flavor development and shelf stability without the risk of over-curing or uneven salt concentrations.

Dry curing vs equilibrium curing for preservation. Infographic

cookingdiff.com

cookingdiff.com