Traditional brine curing for poultry involves soaking the meat in a saltwater solution, which allows for gradual flavor absorption and moisture retention but can be time-consuming and result in uneven distribution. Vacuum brine injection uses a pump to inject the brine directly into the meat, ensuring faster, more uniform curing and enhanced juiciness. This method improves texture and flavor consistency while reducing curing time compared to traditional soaking techniques.

Table of Comparison

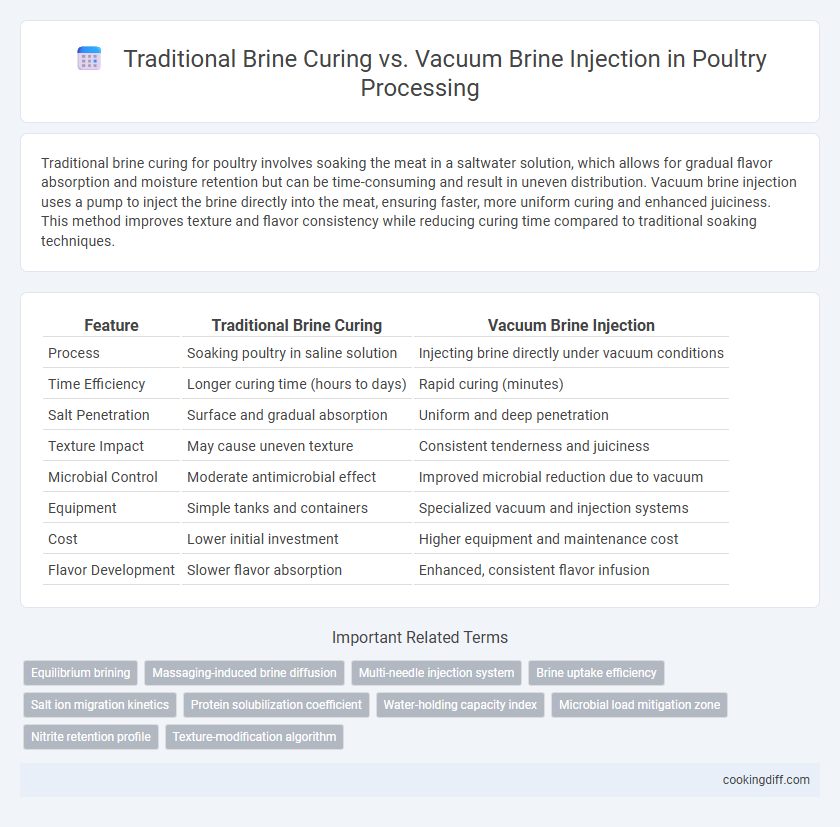

| Feature | Traditional Brine Curing | Vacuum Brine Injection |

|---|---|---|

| Process | Soaking poultry in saline solution | Injecting brine directly under vacuum conditions |

| Time Efficiency | Longer curing time (hours to days) | Rapid curing (minutes) |

| Salt Penetration | Surface and gradual absorption | Uniform and deep penetration |

| Texture Impact | May cause uneven texture | Consistent tenderness and juiciness |

| Microbial Control | Moderate antimicrobial effect | Improved microbial reduction due to vacuum |

| Equipment | Simple tanks and containers | Specialized vacuum and injection systems |

| Cost | Lower initial investment | Higher equipment and maintenance cost |

| Flavor Development | Slower flavor absorption | Enhanced, consistent flavor infusion |

Introduction to Brine Curing in Poultry

Brine curing is a fundamental process in poultry preparation that involves soaking meat in a saltwater solution to enhance flavor, moisture retention, and tenderness. Traditional brine curing relies on immersion, allowing the solution to penetrate the meat gradually over time.

Vacuum brine injection offers a more advanced technique by using pressure to forcibly introduce the brine directly into the poultry, resulting in faster curing and more uniform seasoning. This method improves product consistency and reduces processing time compared to traditional soaking. Both techniques aim to optimize juiciness and flavor but differ significantly in efficiency and penetrative effectiveness.

Overview of Traditional Brine Curing

Traditional brine curing involves immersing poultry in a saltwater solution, allowing gradual absorption of flavors and moisture through osmosis. This method enhances juiciness and tenderness over several hours or days, relying on natural diffusion processes.

It is widely used for its simplicity and ability to develop authentic taste profiles, though curing time can be lengthy. Unlike vacuum brine injection, traditional curing may result in less uniform distribution of the brine within the meat.

How Vacuum Brine Injection Works

Vacuum brine injection for poultry involves injecting a saline solution directly into the meat under vacuum conditions, ensuring deep and uniform penetration. This technique enhances flavor and moisture retention by removing air from the muscle tissues, allowing the brine to distribute evenly throughout the bird.

Traditional brine curing relies on soaking poultry in a saltwater solution, which penetrates slowly over time, often resulting in less consistent seasoning and moisture levels. Vacuum brine injection significantly reduces curing time while improving the texture and juiciness of the meat, making it a preferred method in commercial poultry processing.

Key Differences Between Traditional and Vacuum Brining

Traditional brine curing involves soaking poultry in a saltwater solution for several hours to enhance flavor and moisture retention, whereas vacuum brine injection uses pressure to rapidly infuse the brine deep into the meat. This method significantly reduces curing time and improves uniformity in seasoning and juiciness.

- Process Duration - Traditional brining requires long soaking times, often 12 to 24 hours, while vacuum injection achieves curing in minutes.

- Flavor Penetration - Vacuum brine injection ensures consistent and deeper salt distribution compared to the surface-level absorption of traditional brining.

- Texture Impact - Vacuum injection maintains optimal poultry texture by preventing excessive salt concentration, which can occur in prolonged traditional brining.

Flavor Development: Traditional vs Vacuum Brine Injection

How does flavor development differ between traditional brine curing and vacuum brine injection in poultry? Traditional brine curing allows slow absorption of salt and spices, resulting in a more uniform and intense flavor profile. Vacuum brine injection accelerates flavor penetration, producing juicier meat with enhanced seasoning in a shorter time.

Texture and Moisture Retention Comparison

Traditional brine curing in poultry allows for slower salt penetration, resulting in a firmer texture but often less uniform moisture distribution. Vacuum brine injection enhances moisture retention by forcing the brine deeper into the muscle fibers, producing a juicier and more tender final product. This method significantly improves texture uniformity and overall succulence compared to traditional curing techniques.

Time and Efficiency: Curing Methods Compared

Traditional brine curing for poultry typically requires 12 to 24 hours to achieve adequate flavor penetration and moisture retention. Vacuum brine injection significantly reduces curing time to 30 minutes to 2 hours by forcing the brine directly into the muscle tissue. This method enhances efficiency, allowing higher throughput and more consistent product quality in poultry processing.

Equipment and Skill Requirements for Each Method

Traditional brine curing requires minimal equipment, typically involving large containers for soaking poultry, and relies heavily on manual labor and monitoring skills. Vacuum brine injection demands specialized vacuum tumblers and injection machines, along with trained operators to manage precise pressure and injection cycles.

- Traditional Brine Equipment - Uses simple soaking vats without automation, making setup costs relatively low.

- Vacuum Injection Equipment - Incorporates vacuum tumblers and multi-needle injectors for uniform brine distribution.

- Skill Requirements - Traditional methods need knowledge of curing times and salt concentration, while vacuum injection requires technical expertise in operating and maintaining machinery.

Choosing the appropriate curing method depends on production scale, budget, and available technical skills for equipment operation.

Safety and Consistency in Brine Curing Techniques

Traditional brine curing relies on natural diffusion, which can lead to inconsistent salt distribution and variable microbial safety in poultry. Vacuum brine injection enhances curing uniformity and significantly reduces pathogen risks by forcing brine deep into the tissue under controlled conditions.

- Safety Improvement - Vacuum injection minimizes surface contamination and accelerates pathogen reduction compared to traditional surface brining.

- Consistency in Flavor - Injection ensures even brine penetration, producing uniform taste and texture throughout the poultry product.

- Process Efficiency - Vacuum brine injection shortens curing times and enhances quality control over traditional diffusion methods.

Related Important Terms

Equilibrium brining

Traditional brine curing relies on passive diffusion to achieve salt equilibrium within poultry muscle, resulting in longer processing times and uneven salt distribution. Vacuum brine injection accelerates equilibrium brining by actively forcing the brine into tissues, enhancing moisture retention and uniform salt penetration for improved texture and flavor.

Massaging-induced brine diffusion

Massaging-induced brine diffusion enhances salt and moisture penetration in traditional brine curing by physically working the solution into poultry tissues, promoting uniform flavor and juiciness. Vacuum brine injection accelerates this process by forcing brine directly into muscle fibers, significantly increasing diffusion rate and reducing curing time compared to massaging methods.

Multi-needle injection system

The multi-needle injection system in vacuum brine injection enhances uniform brine distribution throughout poultry, improving flavor and moisture retention compared to traditional brine curing, which relies on slower surface diffusion. This technology reduces curing time and ensures consistent product quality by delivering brine directly into muscle tissues.

Brine uptake efficiency

Traditional brine curing relies on passive diffusion, resulting in lower brine uptake efficiency and uneven distribution in poultry muscles. Vacuum brine injection significantly enhances brine uptake efficiency by forcing the solution deep into the tissue, ensuring faster absorption and uniform seasoning.

Salt ion migration kinetics

Traditional brine curing relies on passive diffusion, resulting in slower salt ion migration kinetics and uneven salt distribution within poultry muscle tissues. Vacuum brine injection significantly accelerates salt ion migration by forcibly introducing brine under reduced pressure, promoting uniform salt penetration and enhanced curing efficiency.

Protein solubilization coefficient

Vacuum brine injection significantly enhances the protein solubilization coefficient in poultry compared to traditional brine curing, leading to improved meat tenderness and moisture retention. Higher protein solubilization accelerates salt penetration and uniform distribution within muscle fibers, optimizing texture and flavor development.

Water-holding capacity index

Traditional brine curing typically results in a moderate water-holding capacity index due to surface diffusion of salt and limited penetration, while vacuum brine injection significantly enhances the water-holding capacity index by uniformly distributing the brine throughout the poultry tissue, minimizing moisture loss during cooking. Studies indicate vacuum brine injection can increase the water-holding capacity index by up to 15-20% compared to traditional methods, improving juiciness and texture in the final product.

Microbial load mitigation zone

Traditional brine curing reduces microbial load on poultry through osmotic dehydration and salt penetration, but the process can be uneven and slower, potentially allowing some bacterial survival. Vacuum brine injection enhances microbial load mitigation by uniformly distributing the curing solution deep into the tissue under reduced pressure, accelerating salt absorption and effectively inhibiting bacterial growth throughout the poultry.

Nitrite retention profile

Traditional brine curing often results in lower nitrite retention in poultry due to slower diffusion and greater exposure to oxidation, leading to reduced efficacy in color and preservation. Vacuum brine injection enhances nitrite retention by forcing the curing solution deep into the tissue under reduced pressure, ensuring uniform distribution and improved antimicrobial effects.

Traditional brine curing vs Vacuum brine injection for poultry. Infographic

cookingdiff.com

cookingdiff.com