Curing a Dutch oven involves seasoning the cast iron by applying oil and heating it to create a durable, non-stick surface that enhances cooking performance and prevents rust. Polymerization is a chemical process during curing where the oil molecules bond and harden on the cookware's surface, forming the protective layer essential for longevity. Proper curing ensures the Dutch oven develops a smooth, black patina, while polymerization is the key reaction that solidifies this beneficial coating.

Table of Comparison

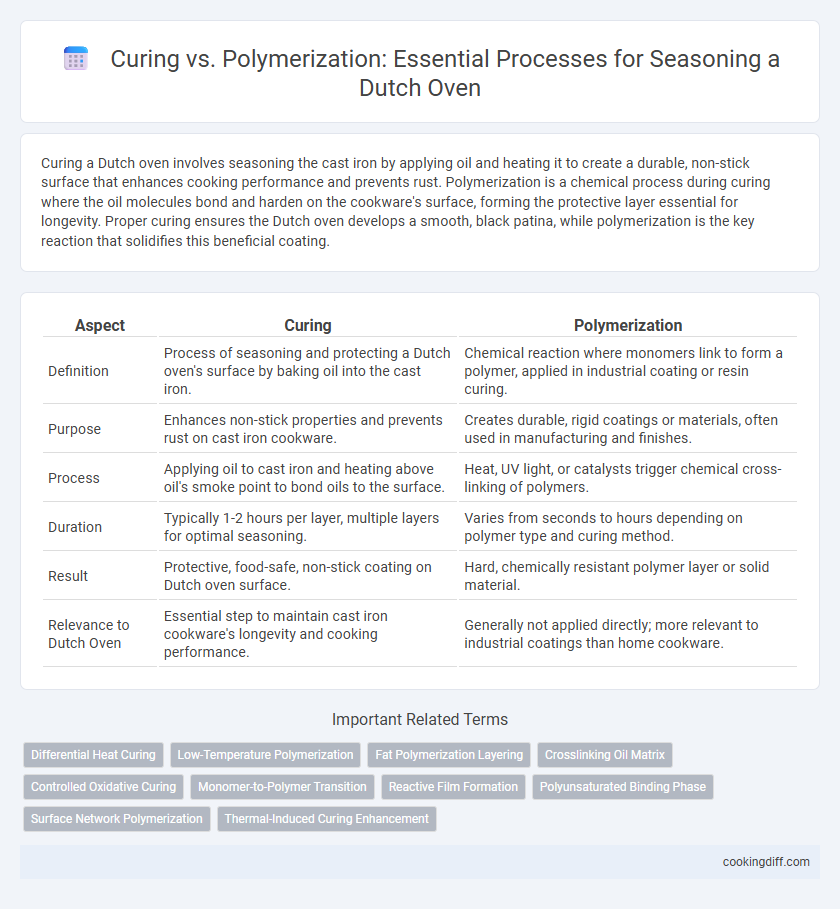

| Aspect | Curing | Polymerization |

|---|---|---|

| Definition | Process of seasoning and protecting a Dutch oven's surface by baking oil into the cast iron. | Chemical reaction where monomers link to form a polymer, applied in industrial coating or resin curing. |

| Purpose | Enhances non-stick properties and prevents rust on cast iron cookware. | Creates durable, rigid coatings or materials, often used in manufacturing and finishes. |

| Process | Applying oil to cast iron and heating above oil's smoke point to bond oils to the surface. | Heat, UV light, or catalysts trigger chemical cross-linking of polymers. |

| Duration | Typically 1-2 hours per layer, multiple layers for optimal seasoning. | Varies from seconds to hours depending on polymer type and curing method. |

| Result | Protective, food-safe, non-stick coating on Dutch oven surface. | Hard, chemically resistant polymer layer or solid material. |

| Relevance to Dutch Oven | Essential step to maintain cast iron cookware's longevity and cooking performance. | Generally not applied directly; more relevant to industrial coatings than home cookware. |

Understanding Curing and Polymerization in Dutch Ovens

Curing in Dutch ovens involves applying oil and heating to create a non-stick, protective layer through oxidation and polymerization of fats. This process improves the cookware's durability and prevents rust by forming a hard, resistant surface.

Polymerization specifically refers to the chemical reaction where oil molecules bond into long chains, solidifying the seasoning layer during curing. Understanding this distinction helps maintain Dutch ovens properly, ensuring optimal performance and longevity.

What is Curing? The Basics for Dutch Ovens

Curing is the process of seasoning a Dutch oven by applying oil and heating it to create a durable, non-stick surface through polymerization of fats. This treatment protects the cast iron from rust and enhances cooking performance by building up a natural, resilient coating. Unlike polymerization alone, curing specifically involves repeated oil application and heating cycles to develop the optimal protective layer on the cookware.

Polymerization Explained: Science Behind Seasoning

Polymerization is the chemical reaction that transforms cooking oil into a hard, plastic-like layer when seasoning a Dutch oven. This process creates a durable, non-stick surface by bonding oil molecules under heat, unlike simple curing which mainly removes moisture and prevents rust.

- Polymerization forms a strong coating - Heat causes unsaturated fats in oil to cross-link, creating a tough, protective layer.

- Seasoning improves over time - Repeated application and heating enhance the polymerized layer's durability and non-stick properties.

- Curing prevents rust but lacks bonding - Curing dries the surface but does not chemically bond oils to form a protective film.

Understanding polymerization helps maximize a Dutch oven's longevity and cooking performance through proper seasoning techniques.

Key Differences: Curing vs Polymerization

Curing in Dutch ovens involves seasoning the cast iron by polymerizing oils to create a non-stick surface and prevent rust. Polymerization refers specifically to the chemical reaction where oil molecules bond under heat, forming a hardened protective layer.

- Curing is a broader process - it includes cleaning, applying oil, and heating to form a durable coating.

- Polymerization is a chemical reaction - it occurs during curing when oils transform into a solid, protective film on the cookware.

- Curing improves cookware longevity - polymerization specifically enhances the surface's non-stick and anti-corrosive properties.

Why Polymerization Matters in Dutch Oven Cooking

| Polymerization | Creates a durable, non-stick coating on the Dutch oven by chemically bonding oil molecules at high heat. |

| Curing | Refers to seasoning the cast iron surface by applying and baking oil to develop a protective layer. |

| Why Polymerization Matters | Polymerization ensures a long-lasting, effective seasoning that prevents rust and improves heat retention, essential for optimal Dutch oven performance. |

Curing Methods for Cast Iron Dutch Ovens

Curing a cast iron Dutch oven involves applying a layer of oil to its surface and heating it to create a natural, non-stick coating through polymerization. This process enhances rust resistance and improves cooking performance by bonding oil molecules to the iron at high temperatures.

Compared to general polymerization, curing specifically targets the porous surface of cast iron, ensuring thorough oil absorption and durability. Effective curing methods include oven curing at 350-400degF for one hour and multiple oil applications to build a strong, protective layer.

The Role of Oils in Curing and Polymerization

Oils play a crucial role in the curing process of Dutch ovens by undergoing polymerization, which forms a durable, non-stick surface. This natural polymerization of oils, such as flaxseed or grapeseed oil, binds the seasoning layer to the cast iron, enhancing its rust resistance and cooking performance.

The polymerization process involves the oxidation of unsaturated fatty acids in the oil when exposed to heat and air, creating a hard, protective coating on the Dutch oven's surface. Unlike basic curing, which may only dry the oil, polymerization chemically transforms the oil molecules into a solid film. Proper application and heating of oils ensure a uniform, long-lasting seasoning layer that improves with each use.

Common Mistakes in Dutch Oven Seasoning

What are the common mistakes when curing versus polymerizing a Dutch oven? Curing involves forming a protective layer through baking oil, while polymerization creates a hardened surface by chemically bonding oil molecules. Confusing these processes often leads to uneven seasoning and sticky residue on the cookware.

Maintenance Tips: Preserving Your Dutch Oven Finish

Proper curing forms a protective layer on your Dutch oven, while polymerization creates a harder, more durable finish through heat-induced chemical bonding. Understanding the difference is key to maintaining the cookware's seasoning and preventing rust effectively.

- Regularly reapply oil after cleaning - This maintains the cured layer, ensuring continued protection against moisture and food residue.

- Avoid harsh detergents - Gentle cleaning preserves the polymerized seasoning, preventing damage to the non-stick surface.

- Store in a dry place - Minimizing exposure to humidity helps preserve both curing and polymerization layers, extending cookware life.

Related Important Terms

Differential Heat Curing

Differential heat curing in Dutch ovens enhances the seasoning layer by applying controlled temperature gradients, ensuring even polymerization of oils into a durable, non-stick coating. Unlike conventional polymerization, this method prevents uneven curing and reduces the risk of sticky or brittle surfaces, optimizing the cookware's longevity and performance.

Low-Temperature Polymerization

Low-temperature polymerization during curing enhances the seasoning layer of a Dutch oven by slowly bonding oils to the cast iron surface, creating a durable non-stick coating. Unlike high-temperature polymerization, this method reduces the risk of overheating, preserving the cookware's structural integrity while maintaining optimal seasoning quality.

Fat Polymerization Layering

Curing a Dutch oven involves creating a fat polymerization layering that forms a durable, non-stick surface by heating oils to high temperatures, causing the fats to polymerize and bond to the cast iron. Unlike simple polymerization, proper curing develops multiple thin layers that build a resilient seasoning, enhancing rust resistance and improving cooking performance.

Crosslinking Oil Matrix

Curing in a Dutch oven involves crosslinking the oil matrix through a controlled oxidation process, forming a durable, non-stick polymerized layer that protects the cast iron surface from rust and enhances cooking performance. Unlike typical polymerization, curing relies on reactive oxygen species to create chemical bonds within the oil's fatty acids, resulting in a robust, heat-resistant seasoning layer critical for maintaining the oven's longevity and seasoning stability.

Controlled Oxidative Curing

Controlled oxidative curing enhances the Dutch oven's seasoning by forming a durable, non-stick carbonized layer through gradual polymer oxidation of oils rather than simple polymerization. This process improves wear resistance and corrosion protection by creating cross-linked, stable compounds that bond tightly to the cast iron surface.

Monomer-to-Polymer Transition

Curing of a Dutch oven's coating involves the monomer-to-polymer transition where liquid monomers chemically bond to form a solid, durable polymer network, enhancing heat resistance and non-stick properties. Unlike polymerization, which often refers to synthetic resin formation, curing in cast iron seasoning solidifies oil molecules into a resilient polymer layer through oxidation and polymer cross-linking.

Reactive Film Formation

Curing of Dutch ovens involves reactive film formation where a thin, polymerized layer chemically bonds to the cast iron surface, enhancing rust resistance and seasoning durability. Unlike standard polymerization, which primarily hardens substances, curing in this context creates a reactive film that improves non-stick properties and extends the cookware's lifespan.

Polyunsaturated Binding Phase

Curing of a Dutch oven involves forming a polyunsaturated binding phase that chemically bonds seasoning oils to the cast iron surface, creating a durable, non-stick coating. Unlike polymerization, which primarily involves cross-linking of monomers, curing emphasizes the oxidative binding of polyunsaturated fatty acids, resulting in improved seasoning stability and enhanced corrosion resistance.

Surface Network Polymerization

Curing in Dutch ovens involves surface network polymerization, where heat triggers cross-linking of oils and fats to form a durable, non-stick coating, enhancing rust resistance and cooking performance. Unlike simple polymerization, this controlled curing process creates a stable, tightly bonded polymer matrix that withstands high temperatures and repeated use without degradation.

Curing vs Polymerization for Dutch Oven Infographic

cookingdiff.com

cookingdiff.com