Wet brining involves soaking meat in a saltwater solution, enhancing moisture retention and seasoning depth, while shio-koji brining uses a fermented rice malt rich in enzymes that tenderize and develop umami flavors. Shio-koji brining promotes a more complex flavor profile and improved texture due to its enzymatic activity, compared to the straightforward salt penetration of wet brining. For charcuterie, shio-koji brining offers a unique depth and subtle sweetness that complements traditional curing methods.

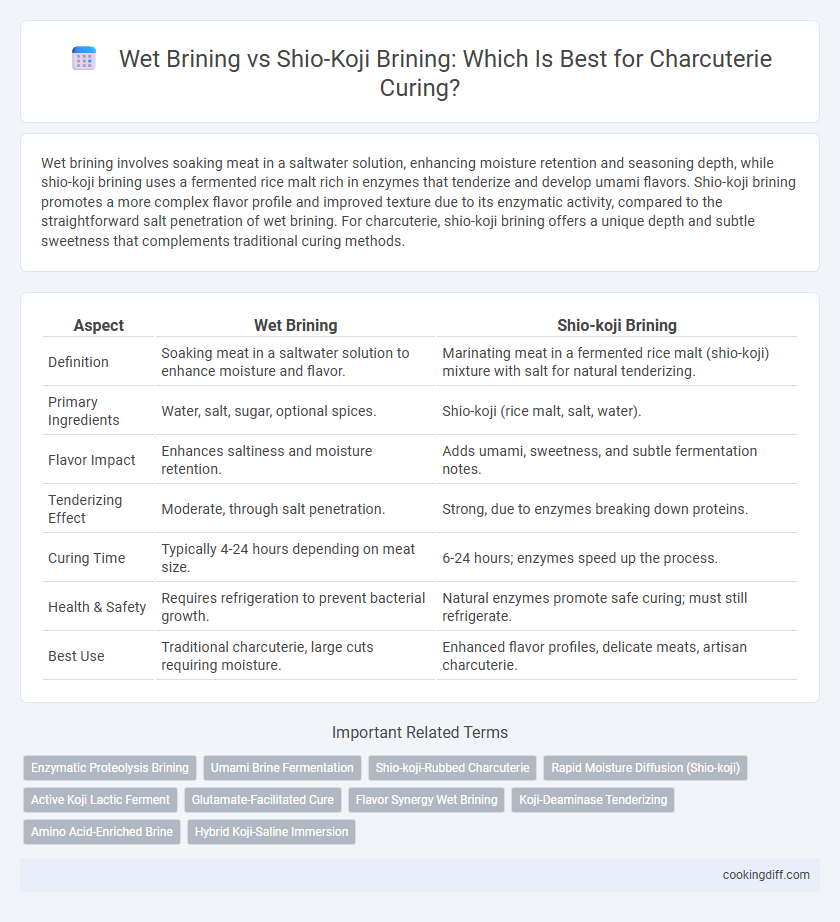

Table of Comparison

| Aspect | Wet Brining | Shio-koji Brining |

|---|---|---|

| Definition | Soaking meat in a saltwater solution to enhance moisture and flavor. | Marinating meat in a fermented rice malt (shio-koji) mixture with salt for natural tenderizing. |

| Primary Ingredients | Water, salt, sugar, optional spices. | Shio-koji (rice malt, salt, water). |

| Flavor Impact | Enhances saltiness and moisture retention. | Adds umami, sweetness, and subtle fermentation notes. |

| Tenderizing Effect | Moderate, through salt penetration. | Strong, due to enzymes breaking down proteins. |

| Curing Time | Typically 4-24 hours depending on meat size. | 6-24 hours; enzymes speed up the process. |

| Health & Safety | Requires refrigeration to prevent bacterial growth. | Natural enzymes promote safe curing; must still refrigerate. |

| Best Use | Traditional charcuterie, large cuts requiring moisture. | Enhanced flavor profiles, delicate meats, artisan charcuterie. |

Introduction to Wet Brining and Shio-koji Brining

Wet brining involves soaking meat in a saline solution to enhance moisture retention and flavor, commonly used in traditional charcuterie. Shio-koji brining utilizes a fermented rice malt rich in enzymes that tenderize meat while imparting umami complexity. Both techniques improve texture and taste but differ in biochemical processes and flavor profiles.

Understanding the Science Behind Brining Methods

What are the key scientific differences between wet brining and shio-koji brining for charcuterie? Wet brining uses a saltwater solution to draw moisture into the meat, enhancing juiciness through osmosis and salt diffusion. Shio-koji brining incorporates koji enzymes and salt, which break down proteins for tenderization and develop umami flavors while preserving moisture.

Key Ingredients: Saltwater vs. Shio-koji

Wet brining uses a saltwater solution to infuse moisture and salt into charcuterie, enhancing flavor and tenderness. The key ingredient, sodium chloride, helps preserve the meat by drawing out moisture and creating an inhospitable environment for bacteria.

Shio-koji brining incorporates a fermented rice malt paste rich in enzymes and umami, which tenderizes meat while adding complex flavors. Its active enzymes break down proteins and sugars, resulting in a more nuanced and naturally sweet taste compared to traditional saltwater brines.

Flavor Development: Comparing Impact on Charcuterie

Wet brining infuses charcuterie with a well-rounded, salty flavor by allowing salt and aromatic compounds to penetrate the meat over time. Shio-koji brining, leveraging naturally occurring enzymes and umami-rich compounds from rice malt fermentation, enhances depth and complexity in flavor beyond mere saltiness. This enzymatic process also tenderizes the meat, resulting in a more nuanced and richly developed charcuterie profile compared to traditional wet brining.

Texture and Tenderness: Results from Each Brine

Wet brining enhances charcuterie texture by allowing salt and moisture to penetrate deeply, resulting in a juicier, more tender product. The solution's water content helps break down muscle fibers, contributing to a soft yet firm bite.

Shio-koji brining uses enzymes from fermented rice malt to tenderize meat while imparting umami flavors, creating a delicate, melt-in-the-mouth texture unique to this method. Its enzymatic action modifies protein structures more gently than traditional wet brines, producing subtle textural refinement.

Fermentation Benefits: Unique Effects of Shio-koji

| Fermentation Benefits of Shio-koji | Shio-koji brining leverages enzymatic activity from Aspergillus oryzae fermentation, enhancing protein breakdown and flavor complexity beyond traditional salt saturation methods used in wet brining. |

| Texture Improvement | Natural enzymes in shio-koji tenderize meat more effectively, producing a delicate, moist charcuterie texture without requiring prolonged curing times associated with wet brining. |

| Umami Development | Fermentation metabolites in shio-koji increase glutamate levels, intensifying umami notes and creating a richer, more savory profile compared to the straightforward salt preservation of wet brining. |

Practical Considerations for Home Charcutiers

Wet brining uses a saltwater solution to enhance moisture and flavor, requiring precise salt ratios and refrigeration. Shio-koji brining employs a fermented rice malt that tenderizes and imparts umami, suitable for those seeking complex flavors without high sodium content.

- Preparation Time - Wet brining typically takes 12 to 24 hours, while shio-koji brining can require 2 to 3 days for optimal effect.

- Ingredient Accessibility - Wet brining uses common pantry ingredients like salt and water; shio-koji requires access to fermented koji culture or premade shio-koji paste.

- Flavor Profile - Wet brining delivers a straightforward salty taste; shio-koji enhances meat with natural sweetness and savory depth due to fermentation enzymes.

Safety and Shelf Life: Wet Brine vs. Shio-koji

Wet brining uses a high concentration of salt and water to inhibit bacterial growth, which enhances safety and typically extends the shelf life of charcuterie by several weeks. Shio-koji, a fermented rice malt with salt, not only introduces beneficial enzymes that improve flavor but also naturally preserves meat by lowering pH and creating an antimicrobial environment.

Safety in wet brining depends on maintaining proper salt levels and refrigeration to prevent pathogen growth, while shio-koji's enzymatic activity can reduce harmful microbes more effectively. Shelf life for wet brined charcuterie typically ranges from three to four weeks under refrigeration, whereas shio-koji brining can extend preservation due to its combined salt and fermentation benefits. Both methods require hygienic handling, but shio-koji offers a natural alternative with probiotic advantages that promote safer, longer-lasting cured meats.

Cost and Accessibility of Brining Ingredients

Wet brining typically requires common ingredients like salt, sugar, and water, making it a cost-effective option widely accessible for charcuterie preparation. Shio-koji brining, using fermented rice malt, may involve higher costs and limited availability depending on regional markets.

- Cost Efficiency of Wet Brining - Relies on inexpensive, readily available ingredients that keep overall brining expenses low.

- Shio-koji Ingredient Accessibility - Fermented rice malt is specialty-priced and might not be available in all grocery stores, increasing difficulty for some charcuterie makers.

- Budget Considerations - Wet brining suits larger scale or budget-conscious projects, whereas shio-koji brining caters to artisanal producers seeking unique flavor profiles regardless of ingredient expense.

Related Important Terms

Enzymatic Proteolysis Brining

Wet brining relies on salt diffusion to enhance moisture and flavor in charcuterie, while Shio-koji brining employs enzymatic proteolysis through Aspergillus oryzae-derived enzymes to break down muscle proteins, resulting in superior tenderness and umami development. The enzymatic action in Shio-koji accelerates protein degradation, improving texture and intensifying savory notes beyond the effects of traditional salt-based wet brining.

Umami Brine Fermentation

Wet brining utilizes a saltwater solution to enhance moisture and basic flavor absorption in charcuterie, while shio-koji brining leverages fermented rice malt enzymes to intensify umami through amino acid breakdown during fermentation. Shio-koji's enzymatic activity promotes deeper protein degradation, resulting in richer taste complexity and superior tenderness compared to traditional wet brines.

Shio-koji-Rubbed Charcuterie

Shio-koji-brined charcuterie offers enhanced umami depth and natural tenderization due to the enzymatic activity of koji mold, which breaks down proteins and fats more effectively than traditional wet brining. This method promotes a complex flavor profile and improved moisture retention, resulting in a succulent, richly flavored cured meat that surpasses the uniform saltiness typical of wet brining.

Rapid Moisture Diffusion (Shio-koji)

Shio-koji brining accelerates rapid moisture diffusion in charcuterie by enzymatically breaking down proteins and enhancing water absorption, resulting in juicier, more flavorful cured meats. Unlike wet brining, which relies primarily on salt diffusion, shio-koji infuses umami compounds and tenderizes meat more effectively for superior texture and taste.

Active Koji Lactic Ferment

Wet brining uses a saltwater solution that primarily enhances moisture retention and flavor penetration in charcuterie, while shio-koji brining leverages active koji lactic ferment to naturally tenderize meat and develop complex umami through enzymatic fermentation. The active koji lactic ferment in shio-koji promotes beneficial microbial growth, improving both preservation and flavor depth beyond traditional wet brining methods.

Glutamate-Facilitated Cure

Wet brining enhances charcuterie by infusing moisture and salt, while shio-koji brining utilizes enzymatic action from Aspergillus oryzae to increase free glutamates, intensifying umami flavors through glutamate-facilitated cure. The higher concentration of natural glutamates in shio-koji accelerates protein breakdown, improving texture and depth in cured meats compared to conventional wet brining.

Flavor Synergy Wet Brining

Wet brining enhances charcuterie by infusing meat with a balanced salt solution that intensifies natural flavors and retains moisture. This method creates a robust flavor synergy through uniform salt penetration, resulting in a tender texture and well-rounded taste.

Koji-Deaminase Tenderizing

Shio-koji brining leverages the enzymatic activity of koji-deaminase to break down proteins, resulting in a more tender and flavorful charcuterie compared to traditional wet brining, which primarily uses salt for moisture retention and mild flavor enhancement. This enzyme-driven process enhances umami and improves texture by accelerating protein degradation during curing.

Amino Acid-Enriched Brine

Shio-koji brining enhances charcuterie by introducing an amino acid-enriched brine through the fermentation of rice, soybeans, and salt, which intensifies umami flavors and tenderizes meat more effectively than traditional wet brining. This method leverages naturally occurring enzymes and amino acids to improve moisture retention and develop complex taste profiles critical for high-quality cured meats.

Wet Brining vs Shio-koji Brining for charcuterie. Infographic

cookingdiff.com

cookingdiff.com