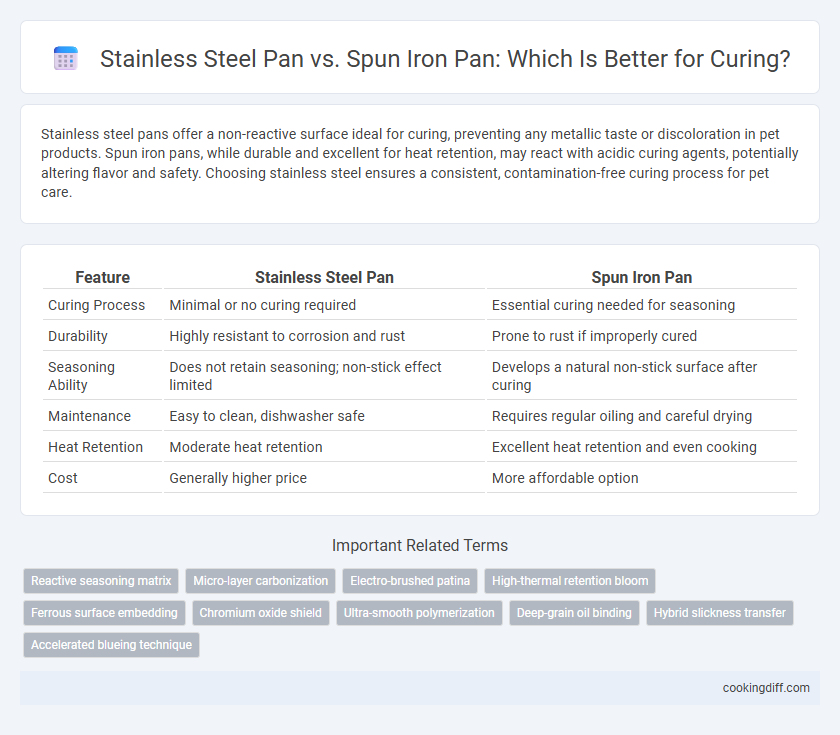

Stainless steel pans offer a non-reactive surface ideal for curing, preventing any metallic taste or discoloration in pet products. Spun iron pans, while durable and excellent for heat retention, may react with acidic curing agents, potentially altering flavor and safety. Choosing stainless steel ensures a consistent, contamination-free curing process for pet care.

Table of Comparison

| Feature | Stainless Steel Pan | Spun Iron Pan |

|---|---|---|

| Curing Process | Minimal or no curing required | Essential curing needed for seasoning |

| Durability | Highly resistant to corrosion and rust | Prone to rust if improperly cured |

| Seasoning Ability | Does not retain seasoning; non-stick effect limited | Develops a natural non-stick surface after curing |

| Maintenance | Easy to clean, dishwasher safe | Requires regular oiling and careful drying |

| Heat Retention | Moderate heat retention | Excellent heat retention and even cooking |

| Cost | Generally higher price | More affordable option |

Introduction to Curing in Cooking

| Stainless steel pans offer an inert surface that does not react with curing agents, ensuring consistent flavor retention during the curing process. Spun iron pans provide superior heat retention and even heat distribution, enhancing the chemical reactions involved in curing meats and preserving texture. Understanding the thermal properties and material reactivity of these pans is essential to optimize curing results in culinary applications. |

Overview: Stainless Steel Pan vs Spun Iron Pan

Stainless steel pans offer a non-reactive surface ideal for curing acidic foods without imparting metallic flavors, while spun iron pans provide excellent heat retention and develop a natural seasoning over time that enhances curing processes. Both materials serve unique roles in curing, with stainless steel favored for durability and ease of cleaning, and spun iron valued for its traditional seasoning benefits and thermal conductivity.

- Stainless Steel Durability - Resistant to rust and corrosion, providing long-lasting use during curing.

- Spun Iron Heat Retention - Holds and distributes heat evenly, facilitating consistent curing temperatures.

- Non-Reactive Surface - Stainless steel prevents chemical interactions that could affect food flavor during curing.

Choosing between stainless steel and spun iron pans depends on the desired curing outcome, balancing ease of maintenance against traditional seasoning benefits.

Material Properties and Heat Conductivity

Stainless steel pans offer superior corrosion resistance and durability due to their alloy composition, making them less reactive during the curing process. Their moderate thermal conductivity ensures even heat distribution but at a slower rate compared to spun iron.

Spun iron pans excel in high heat retention and rapid thermal conductivity because of their dense material structure, facilitating more efficient curing. The porous nature of iron can enhance flavor development but requires regular seasoning to prevent rust. Choosing between the two depends on balancing heat management with maintenance preferences during curing.

Reactivity and Flavor Impacts

Stainless steel pans exhibit low reactivity, preventing any metallic taste from leaching into the food during curing processes, making them ideal for preserving original flavors. In contrast, spun iron pans can react with acidic or alkaline ingredients, potentially altering flavor profiles and imparting a subtle metallic taste. Choosing stainless steel ensures a neutral environment that maintains the intended flavor integrity during curing.

Surface Texture and Oil Absorption

How do the surface texture and oil absorption properties differ between stainless steel pans and spun iron pans for curing? Stainless steel pans have a smooth, non-porous surface that resists oil absorption, making them less effective at retaining seasoning layers during curing. Spun iron pans feature a slightly rougher, porous surface that absorbs oil better, enhancing the development of a natural non-stick patina over time.

Durability and Maintenance Needs

Stainless steel pans offer superior durability due to their corrosion resistance and ability to withstand high temperatures without warping. Spun iron pans, while robust, require regular seasoning to prevent rust and maintain their non-stick properties. Stainless steel demands less maintenance, making it ideal for long-term use, whereas spun iron needs consistent care to ensure longevity and performance.

Curing Process: Stainless Steel Pan

The curing process for a stainless steel pan involves seasoning the surface to create a non-stick layer that enhances cooking performance and prevents food from sticking. Unlike cast iron, stainless steel pans require less frequent curing but still benefit from oil seasoning to improve durability and resistance to rust.

Proper curing of stainless steel pans includes heating oil to its smoke point and spreading it evenly to fill microscopic pores on the pan's surface. This method also helps in forming a protective barrier that maintains the pan's natural corrosion resistance and promotes even heat distribution during cooking.

Curing Process: Spun Iron Pan

The curing process for a spun iron pan involves heating the pan with oil to create a natural non-stick coating and prevent rust. This method enhances the pan's durability and improves cooking performance over time.

- Heat Retention - Spun iron pans hold heat evenly, allowing thorough polymerization of oils during curing.

- Porous Surface - The iron's slightly rough texture absorbs oil, forming a stronger seasoning layer than stainless steel.

- Rust Prevention - Proper curing creates a protective barrier against oxidation and moisture damage.

Pros and Cons Comparison

Stainless steel pans offer excellent resistance to corrosion and are non-reactive, making them ideal for curing acidic ingredients without altering flavor. Their durability and ease of cleaning reduce maintenance time and prevent contamination during the curing process.

Spun iron pans provide superior heat retention and even distribution, which enhances the curing of meats by maintaining consistent temperatures. However, they require regular seasoning to prevent rust and can react with acidic foods, potentially affecting taste.

Related Important Terms

Reactive seasoning matrix

Stainless steel pans develop a reactive seasoning matrix more slowly than spun iron pans due to their smoother, non-porous surface which limits oil absorption and polymerization. Spun iron pans, with their porous microstructure, enhance the curing process by better bonding oils to metal, creating a more durable and effective seasoning layer.

Micro-layer carbonization

Stainless steel pans offer a non-porous surface that limits micro-layer carbonization, preserving flavor without forming a seasoned patina. Spun iron pans excel in micro-layer carbonization by developing a durable, carbonized coating that enhances non-stick properties and enriches taste over time.

Electro-brushed patina

Electro-brushed patina on stainless steel pans provides a durable, non-reactive surface ideal for curing, preventing rust and contamination. Spun iron pans develop a natural seasoning over time through curing but require regular maintenance to maintain their protective patina and avoid oxidation.

High-thermal retention bloom

Spun iron pans outperform stainless steel pans in curing applications due to their superior high-thermal retention, which ensures even heat distribution and consistent bloom development. The dense iron material maintains stable temperatures longer, enhancing the curing process by promoting uniform texture and flavor infusion in food.

Ferrous surface embedding

Ferrous surface embedding in spun iron pans enhances seasoning retention by allowing oils to bond deeply within the porous iron matrix, creating a natural non-stick layer that improves with use. Stainless steel pans, lacking this porous ferrous surface, do not facilitate the same level of seasoning embedding, resulting in less effective curing and a more maintenance-intensive surface.

Chromium oxide shield

Stainless steel pans develop a Chromium oxide shield that enhances corrosion resistance and durability during the curing process, preventing metal leaching and maintaining food safety. Spun iron pans lack this protective layer, requiring regular seasoning to form a natural patina that aids in curing but demands more maintenance to avoid rust and degradation.

Ultra-smooth polymerization

Stainless steel pans offer ultra-smooth polymerization surfaces that enhance curing by promoting even heat distribution and preventing sticking. Spun iron pans, while durable, have a rougher texture that can lead to uneven curing and less consistent polymerized coatings.

Deep-grain oil binding

Stainless steel pans have a smooth, non-porous surface that resists deep-grain oil binding, making them less effective for curing processes that require oil absorption. Spun iron pans, with their porous texture, facilitate deep oil penetration, enhancing the seasoning and curing by locking oils into the metal's grain structure for superior heat retention and flavor development.

Hybrid slickness transfer

Stainless steel pans offer superior durability and resistance to corrosion during curing but lack the heat retention and even slickness transfer characteristic of spun iron pans. Hybrid slickness transfer is optimized by combining the thermal conductivity of spun iron with the non-reactive surface of stainless steel, ensuring consistent curing and enhanced flavor development.

Stainless steel pan vs spun iron pan for curing. Infographic

cookingdiff.com

cookingdiff.com