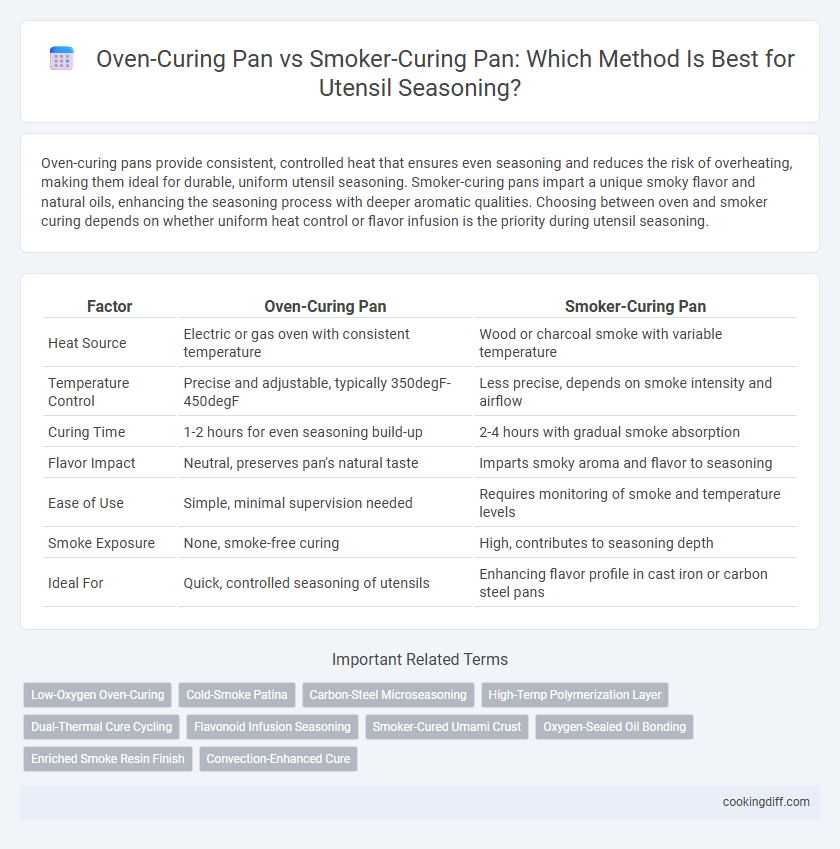

Oven-curing pans provide consistent, controlled heat that ensures even seasoning and reduces the risk of overheating, making them ideal for durable, uniform utensil seasoning. Smoker-curing pans impart a unique smoky flavor and natural oils, enhancing the seasoning process with deeper aromatic qualities. Choosing between oven and smoker curing depends on whether uniform heat control or flavor infusion is the priority during utensil seasoning.

Table of Comparison

| Factor | Oven-Curing Pan | Smoker-Curing Pan |

|---|---|---|

| Heat Source | Electric or gas oven with consistent temperature | Wood or charcoal smoke with variable temperature |

| Temperature Control | Precise and adjustable, typically 350degF-450degF | Less precise, depends on smoke intensity and airflow |

| Curing Time | 1-2 hours for even seasoning build-up | 2-4 hours with gradual smoke absorption |

| Flavor Impact | Neutral, preserves pan's natural taste | Imparts smoky aroma and flavor to seasoning |

| Ease of Use | Simple, minimal supervision needed | Requires monitoring of smoke and temperature levels |

| Smoke Exposure | None, smoke-free curing | High, contributes to seasoning depth |

| Ideal For | Quick, controlled seasoning of utensils | Enhancing flavor profile in cast iron or carbon steel pans |

Introduction to Utensil Seasoning Methods

| Oven-curing pans utilize controlled, consistent heat to polymerize seasoning oils, creating a durable, non-stick coating ideal for utensils. Smoker-curing pans employ lower temperature heat combined with smoke, imparting unique flavors and a natural patina to the utensil surface. Both methods enhance utensil longevity and cooking performance, but oven-curing offers faster seasoning development while smoker-curing provides enhanced flavor complexity. |

What Is Oven-Curing for Pan Seasoning?

Oven-curing for pan seasoning involves heating the pan at a controlled temperature to polymerize oil onto the surface, creating a non-stick, rust-resistant coating. This method provides consistent heat distribution, ensuring even seasoning and a durable finish. Compared to smoker-curing, oven-curing reduces exposure to smoke particles, resulting in a cleaner, more uniform seasoning layer.

What Is Smoker-Curing for Pan Seasoning?

Smoker-curing for pan seasoning involves using wood smoke to infuse the pan's surface with a layer of natural oils and phenolic compounds, creating a durable, non-stick coating. This method enhances the pan's flavoring properties by incorporating aromatic smoke particles that penetrate the seasoning layers.

Compared to oven-curing, smoker-curing allows for lower temperatures and avoids the breakdown of seasoning oils due to direct heat exposure. The slow, smoky environment promotes a deeper, more resilient seasoning bond on cast iron and carbon steel cookware.

Heat Control: Oven vs Smoker in Utensil Curing

Oven-curing pans provide consistent and precise heat control, ensuring even seasoning layers on utensils. In contrast, smoker-curing pans offer variable heat and smoke infusion, creating distinct flavor profiles but less uniform seasoning.

- Oven temperature regulation - Electric ovens maintain stable temperatures ideal for consistent polymerization of oils during seasoning.

- Smoker heat variability - Smokers have fluctuating heat influenced by fuel type and airflow, affecting utensil curing uniformity.

- Flavor infusion difference - Smokers add smoky aromas to utensils while ovens focus purely on heat for surface curing without flavor alteration.

Flavor Impacts: Oven-Cured vs Smoker-Cured Pans

Oven-curing pans produce a neutral, pure seasoning layer that preserves the original flavor of cooked food without imparting additional aromas. Smoker-curing pans infuse utensil surfaces with smoky compounds, which subtly enhance flavors during cooking, especially in cast iron skillets.

- Oven-curing results in a clean, odorless seasoning - Ideal for versatile cooking when flavor neutrality is desired.

- Smoker-curing adds smoky aroma to the pan surface - Enhances dishes with a mild, natural smoky flavor.

- Flavor retention differs between methods - Oven seasoning maintains original food taste whereas smoker curing integrates smoke essence into meals.

Ease of Use: Oven-Curing Pan vs Smoker-Curing Pan

Which method offers greater ease of use for utensil seasoning: oven-curing pan or smoker-curing pan? Oven-curing pans provide precise temperature control and consistent heat distribution, making the seasoning process straightforward and reliable. Smoker-curing pans require more attention to airflow and temperature monitoring, which can complicate the seasoning process for beginners.

Equipment and Setup Requirements

Oven-curing pans require a controlled, high-temperature environment to properly season utensils, ensuring uniform heat distribution and optimal seasoning adherence. Smoker-curing pans rely on lower temperatures combined with smoke exposure, demanding specialized ventilation and temperature monitoring to infuse flavor while curing.

- Temperature control - Ovens maintain steady, precise temperatures essential for consistent seasoning layers.

- Ventilation system - Smokers require adequate smoke circulation and exhaust to avoid bitterness and ensure even curing.

- Space requirements - Oven setups typically need less room compared to bulkier smoker-curing equipment.

Choosing between oven-curing and smoker-curing pans depends on available space, desired flavor infusion, and control over curing conditions.

Durability and Quality of Seasoned Layer

Oven-curing pans provide a consistent, high-temperature environment that enhances the durability of the seasoned layer by ensuring even polymerization of the oil. Smoker-curing pans introduce smoke particles that contribute to a unique flavor profile but may result in a less uniform seasoning layer prone to flaking over time. For long-term utensil seasoning, oven-curing pans generally produce a superior quality and more resilient non-stick surface.

Cleaning and Maintenance After Curing

Oven-curing pans require less frequent deep cleaning as their controlled heat reduces residue buildup, allowing for simpler maintenance with mild detergents and warm water. Smoker-curing pans accumulate more smoky residue and grease, necessitating thorough scrubbing and occasional soaking to prevent residue buildup and maintain seasoning quality.

After oven-curing, avoid abrasive cleaning tools to preserve the pan's seasoning layer and lightly oil the surface to prevent rust. Smoker-curing pans should be cleaned promptly after use with a stiff brush and hot water, followed by drying and oiling to protect against corrosion. Regular maintenance for both types ensures optimal performance and longevity of the utensil seasoning.

Related Important Terms

Low-Oxygen Oven-Curing

Low-oxygen oven-curing pan seasoning effectively minimizes oxidation and enhances the durability of cookware by creating a controlled environment, unlike smoker-curing which exposes pans to volatile compounds and inconsistent temperature. Precision temperature regulation in low-oxygen ovens ensures uniform polymerization of oil layers, resulting in superior non-stick properties and prolonged pan lifespan.

Cold-Smoke Patina

Oven-curing pans provide consistent heat essential for developing a uniform seasoning layer, while smoker-curing pans enhance utensil seasoning by infusing a distinct Cold-Smoke Patina that improves flavor and corrosion resistance. Cold-Smoke Patina formed during smoker-curing creates a more natural, porous surface ideal for long-term utensil durability compared to the denser finish from oven-curing.

Carbon-Steel Microseasoning

Oven-curing a carbon-steel pan develops a uniform microseasoning layer by maintaining consistent high heat that polymerizes oils evenly across the surface. Smoker-curing introduces smoky flavors and uneven temperature zones which can create patchy microseasoning, potentially compromising the pan's durability and non-stick properties.

High-Temp Polymerization Layer

Oven-curing pans develop a high-temp polymerization layer through controlled dry heat, resulting in a durable and evenly distributed seasoning resistant to flaking. Smoker-curing pans rely on lower temperature smoke infusion, producing a thinner polymerized layer that may lack the robustness and uniformity of oven-cured seasoning.

Dual-Thermal Cure Cycling

Dual-Thermal Cure Cycling enhances the seasoning process by precisely controlling temperature fluctuations that optimize oil polymerization on oven-curing pans, resulting in a durable, non-stick surface. Smoker-curing pans leverage this technique to infuse flavor while maintaining seasoning integrity through lower temperature gradients and smoke exposure.

Flavonoid Infusion Seasoning

Oven-curing pans enable precise temperature control that promotes uniform flavonoid infusion seasoning, enhancing the pan's natural non-stick properties and flavor retention. Smoker-curing pans impart a distinct smoky aroma and deeper flavonoid complexity through controlled combustion gases, intensifying the seasoning layer with unique antioxidant benefits.

Smoker-Cured Umami Crust

Smoker-curing pans develop a rich umami crust through slow, smoke-infused seasoning, enhancing flavor depth and creating a naturally non-stick surface ideal for cooking. Oven-curing pans lack this smoky complexity, resulting in a less robust umami profile and a comparatively uniform seasoning layer.

Oxygen-Sealed Oil Bonding

Oven-curing pans create an oxygen-sealed oil bonding through precise temperature control, ensuring uniform polymerization of the seasoning layer for enhanced non-stick properties. Smoker-curing pans rely on smoke compounds that may introduce uneven oxygen exposure, leading to less consistent seasoning adhesion and potential flaking over time.

Enriched Smoke Resin Finish

Oven-curing pans provide a consistent high heat environment that allows smoke resins to fully polymerize, creating a durable, enriched resin finish on utensils. Smoker-curing pans infuse natural wood smoke compounds into the surface, enhancing flavor and imparting a unique, rich resin coating that improves seasoning longevity.

Oven-curing pan vs smoker-curing pan for utensil seasoning. Infographic

cookingdiff.com

cookingdiff.com