Hand-pumped briners allow for precise control over the marinade infusion, making them ideal for small-scale curing with uniform salt distribution. Vacuum tumblers accelerate the curing process by creating a low-pressure environment that forces the brine deep into the meat, resulting in enhanced flavor penetration and reduced curing time. Choosing between the two depends on batch size and desired curing speed, with hand-pumped briners favored for artisanal quality and vacuum tumblers suited for efficiency in larger operations.

Table of Comparison

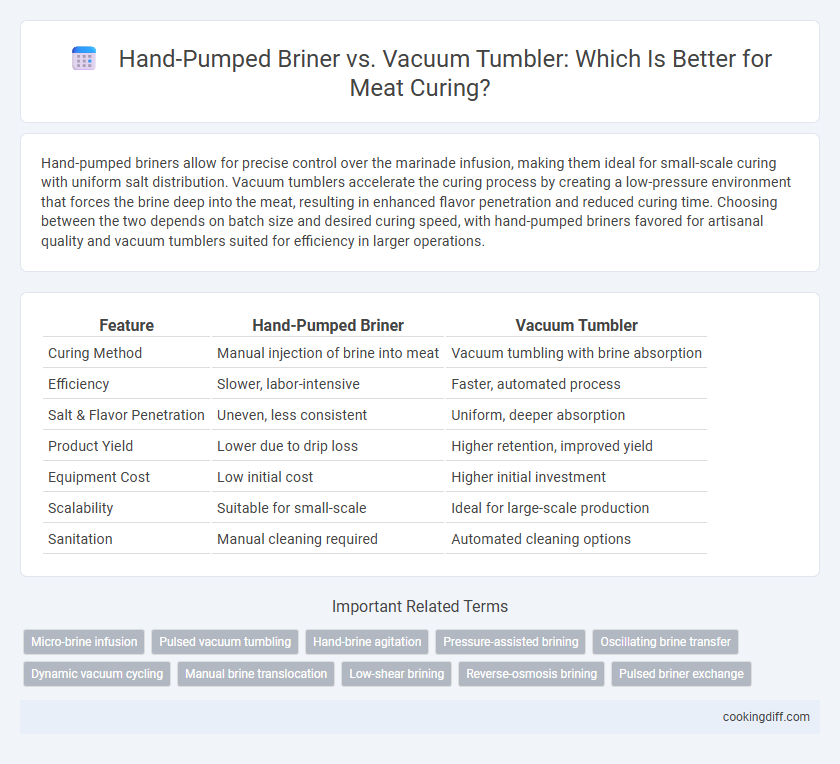

| Feature | Hand-Pumped Briner | Vacuum Tumbler |

|---|---|---|

| Curing Method | Manual injection of brine into meat | Vacuum tumbling with brine absorption |

| Efficiency | Slower, labor-intensive | Faster, automated process |

| Salt & Flavor Penetration | Uneven, less consistent | Uniform, deeper absorption |

| Product Yield | Lower due to drip loss | Higher retention, improved yield |

| Equipment Cost | Low initial cost | Higher initial investment |

| Scalability | Suitable for small-scale | Ideal for large-scale production |

| Sanitation | Manual cleaning required | Automated cleaning options |

Introduction to Meat Curing Techniques

What are the key differences between hand-pumped briners and vacuum tumblers in meat curing? Hand-pumped briners infuse meat with curing solutions manually, allowing gradual absorption and enhanced flavor penetration. Vacuum tumblers use negative pressure to accelerate curing by rapidly distributing brine, improving texture and reducing processing time.

What is a Hand-Pumped Briner?

A hand-pumped briner is a manual device used to inject curing solutions into meat, ensuring even distribution of brine. It operates by creating pressure through a hand-operated pump, allowing the brine to penetrate deeply and enhance flavor and preservation. This method is favored in artisanal and small-scale meat curing for precise control over the curing process.

Understanding Vacuum Tumblers

Vacuum tumblers use a sealed drum to immerse meat in curing solutions, enhancing the penetration of brine by creating a vacuum that opens muscle fibers for deeper absorption. This method significantly reduces curing time compared to traditional hand-pumped briners by improving the uniformity and efficiency of flavor distribution.

The vacuum environment prevents oxidation and bacterial contamination, ensuring a safer curing process with improved texture and quality. While hand-pumped briners rely on manual pressure to infuse brine, vacuum tumblers automate the process, offering consistent results and scalability for commercial meat processing.

How Each Method Infuses Cure

Hand-pumped briners rely on manual pressure to evenly distribute the curing solution throughout the meat, allowing the brine to penetrate slowly and uniformly. This method is effective for ensuring that the cure reaches deeper muscle tissues over time.

Vacuum tumblers, on the other hand, use a vacuum and mechanical tumbling action to rapidly infuse the cure by opening the meat's pores and forcing the brine inside. This accelerated process enhances flavor absorption and reduces curing time significantly.

Speed and Efficiency Comparison

| Method | Speed | Efficiency |

|---|---|---|

| Hand-pumped briner | Slower brine absorption, typically several hours to days | Manual process with uneven distribution, requires frequent monitoring |

| Vacuum tumbler | Accelerates brine penetration, curing completed in 30 minutes to 2 hours | Automated tumbling ensures uniform cure and improved flavor infusion |

Flavor and Texture Outcomes

Hand-pumped brining allows for a slower, more controlled infusion of flavors, resulting in a deeper, more natural taste and a firmer texture in cured meats. Vacuum tumblers accelerate the curing process by forcing brine into the meat, enhancing flavor penetration quickly but sometimes producing a softer, less textured product. Flavor intensity in hand-pumped brined meat tends to be more balanced, while vacuum tumblers yield a stronger, sometimes less nuanced flavor profile due to the mechanical action.

Equipment Cost and Maintenance

Hand-pumped briners have significantly lower initial equipment costs compared to vacuum tumblers, making them ideal for small-scale operations. Vacuum tumblers require higher investment and regular maintenance to ensure optimal performance and longevity.

- Equipment Cost - Hand-pumped briners typically cost a fraction of the price of industrial vacuum tumblers, lowering entry barriers for startups.

- Maintenance Frequency - Vacuum tumblers need routine maintenance such as seal replacement and motor lubrication to prevent breakdowns.

- Operational Durability - Hand-pumped briners demand minimal upkeep but may suffer wear faster under heavy usage.

Suitability for Home vs Commercial Use

Hand-pumped briners are often ideal for home curing due to their simplicity, affordability, and ease of use in small batches. Vacuum tumblers offer enhanced brine absorption and are better suited for commercial operations requiring higher throughput and consistent product quality.

For home use, hand-pumped briners provide control over curing time without the need for specialized equipment or electricity. Commercial environments benefit from vacuum tumblers' ability to speed up the curing process, improving efficiency and uniformity across large volumes of meat. This makes vacuum tumblers essential for maintaining product standards and meeting high demand in professional settings.

Safety and Consistency Factors

Hand-pumped briners require manual operation, increasing the risk of inconsistent brine distribution and potential contamination. Vacuum tumblers ensure uniform curing and reduce microbial growth by creating a controlled, sealed environment.

- Safety - Vacuum tumblers minimize exposure to contaminants through airtight processing, enhancing food safety.

- Consistency - Vacuum tumblers deliver even brine absorption, resulting in uniform flavor and texture.

- Risk - Manual hand-pumping introduces variability in pressure and brine levels, increasing safety and quality risks.

Related Important Terms

Micro-brine infusion

Hand-pumped briners rely on manual pressure to force micro-brine infusion into meat, resulting in uneven penetration and longer curing times compared to vacuum tumblers. Vacuum tumblers create a low-pressure environment that enhances micro-brine infusion by expanding meat fibers, allowing faster and more uniform curing throughout the product.

Pulsed vacuum tumbling

Pulsed vacuum tumbling enhances curing efficiency by repeatedly applying vacuum pulses that improve brine absorption and distribution within meat, significantly outperforming traditional hand-pumped briners in penetration depth and uniformity. This method reduces curing time and improves product texture and flavor retention, making it a preferred choice in modern meat processing.

Hand-brine agitation

Hand-pumped briner agitation ensures consistent distribution of curing solutions by manually circulating brine, enhancing meat absorption and flavor penetration. Unlike vacuum tumblers, this method relies on physical motion without pressurization, preserving meat texture while promoting even curing.

Pressure-assisted brining

Pressure-assisted brining using vacuum tumblers accelerates salt and flavor absorption by creating a low-pressure environment that enhances brine penetration into meat fibers, resulting in more uniform curing compared to traditional hand-pumped briners. Vacuum tumblers improve texture and reduce processing time, while hand-pumped briners rely on manual pressure application, leading to less consistent results and longer cure cycles.

Oscillating brine transfer

Hand-pumped briners rely on manual oscillating brine transfer to evenly distribute curing solutions, ensuring consistent penetration in small-scale or artisanal meat processing. Vacuum tumblers utilize controlled pressure and oscillation to enhance brine absorption rapidly, improving texture and flavor uniformity in industrial curing applications.

Dynamic vacuum cycling

Dynamic vacuum cycling in hand-pumped briners enhances brine penetration by repeatedly applying and releasing vacuum pressure, promoting uniform flavor absorption and moisture retention in cured meats. Vacuum tumblers automate this process, offering precise control over vacuum levels and tumbling speed, resulting in faster curing times and improved product consistency.

Manual brine translocation

Hand-pumped briners enable precise manual brine translocation by evenly distributing curing solution through muscle fibers, enhancing flavor penetration and texture uniformity in meat products. Vacuum tumblers, while efficient in mass curing, rely on mechanical tumbling and vacuum pressure, which may result in less controlled brine placement compared to the tactile accuracy offered by hand-pumped methods.

Low-shear brining

Hand-pumped briners provide low-shear brining by gently infusing curing solutions into meat, preserving texture and preventing protein damage. In contrast, vacuum tumblers use mechanical action that increases shear forces, potentially altering meat structure and accelerating cure uptake but risking tougher texture.

Reverse-osmosis brining

Reverse-osmosis brining enhances salt uptake and uniformity in cured products by controlling water composition and osmotic pressure, making it highly effective in hand-pumped briner systems that rely on manual solution circulation. Vacuum tumblers mechanically agitate meat under low pressure, accelerating brine absorption but may offer less precise control over osmotic conditions than reverse-osmosis methods, impacting curing consistency and flavor development.

Hand-pumped briner vs vacuum tumbler for curing. Infographic

cookingdiff.com

cookingdiff.com