Oven seasoning uses controlled heat to cure pets, enhancing flavor and texture while reducing bacterial risk through consistent temperature exposure. Cold smoke seasoning imparts a distinct smoky flavor without cooking, preserving natural moisture but requiring careful monitoring to prevent spoilage. Both methods offer unique taste profiles; however, oven seasoning provides a safer and faster curing process.

Table of Comparison

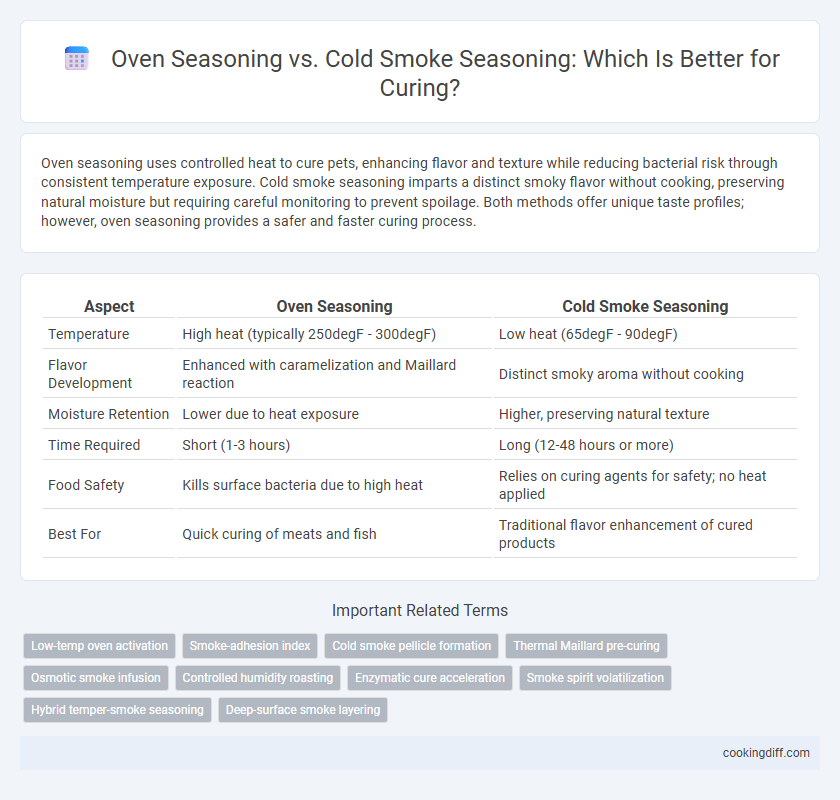

| Aspect | Oven Seasoning | Cold Smoke Seasoning |

|---|---|---|

| Temperature | High heat (typically 250degF - 300degF) | Low heat (65degF - 90degF) |

| Flavor Development | Enhanced with caramelization and Maillard reaction | Distinct smoky aroma without cooking |

| Moisture Retention | Lower due to heat exposure | Higher, preserving natural texture |

| Time Required | Short (1-3 hours) | Long (12-48 hours or more) |

| Food Safety | Kills surface bacteria due to high heat | Relies on curing agents for safety; no heat applied |

| Best For | Quick curing of meats and fish | Traditional flavor enhancement of cured products |

Understanding Oven Seasoning and Cold Smoke Seasoning

Oven seasoning uses controlled heat to infuse flavors and partially cure meats, enhancing texture and taste through consistent temperatures. Cold smoke seasoning imparts a smoky flavor at low temperatures without cooking, preserving the meat's raw characteristics while adding depth.

- Oven seasoning - Applies heat typically between 140degF to 160degF, accelerating curing and flavor penetration.

- Cold smoke seasoning - Uses smoke at temperatures below 90degF to avoid cooking while infusing smoke flavor over extended periods.

- Flavor impact - Oven seasoning results in a cooked texture with intensified flavors, whereas cold smoke maintains a raw texture with a delicate smoky aroma.

Key Differences Between Oven and Cold Smoke Seasoning

Oven seasoning for curing relies on controlled heat, promoting faster flavor penetration and enzyme activation, while cold smoke seasoning uses low temperatures to infuse smoky flavors without cooking the meat. Oven seasoning typically reaches temperatures between 140-180degF, whereas cold smoking maintains below 90degF to preserve texture and moisture.

Key differences include the impact on moisture retention, with cold smoke seasoning better preserving juiciness, and the flavor profile, where oven seasoning produces a more intense, caramelized taste. Safety considerations also vary, as cold smoke seasoning requires careful temperature control to prevent bacterial growth during the curing process.

How Oven Seasoning Enhances Flavor in Curing

Oven seasoning intensifies flavor by applying consistent heat that activates aromatic compounds and enhances the Maillard reaction during curing. This process creates deeper, richer taste profiles compared to cold smoke seasoning, which relies primarily on smoke infusion at low temperatures.

- Heat Activation - Oven seasoning uses controlled heat to release and blend spices, enriching the cured product's flavor complexity.

- Maillard Reaction Enhancement - The dry heat promotes caramelization and browning, intensifying savory and sweet notes in the cured meat.

- Flavor Penetration - Oven seasoning ensures more uniform absorption of seasoning flavors by gently cooking the product through gradual temperature increase.

Benefits of Cold Smoke Seasoning in the Curing Process

Cold smoke seasoning enhances the curing process by imparting a delicate smoky flavor without raising the meat's temperature, preserving its texture and moisture. This method reduces the risk of bacterial growth associated with heat, ensuring safer preservation.

By using cold smoke seasoning, the meat absorbs aromatic compounds that deepen its flavor complexity over time. It also allows for longer curing periods, improving tenderness and shelf life. This technique is particularly beneficial for delicate cuts that might otherwise be compromised by oven seasoning's higher temperatures.

Step-by-Step Guide to Oven Seasoning for Curing

Oven seasoning for curing involves thoroughly drying and heating the meat at a controlled temperature of 150-160degF (65-70degC) for several hours to enhance flavor and shelf life. Begin by rubbing the meat with a dry cure mixture, placing it on a wire rack inside a preheated oven, and allowing the heat to penetrate evenly without cooking the meat. This method contrasts with cold smoke seasoning, which uses low-temperature smoke to impart flavor without heat, making oven seasoning ideal for quicker curing processes requiring precise temperature control.

Techniques for Effective Cold Smoke Seasoning

Cold smoke seasoning involves exposing food to smoke at temperatures below 90degF, preserving texture and enhancing flavor without cooking. Techniques include using hardwood chips like hickory or applewood, maintaining consistent low temperatures, and controlling humidity for optimal smoke absorption.

Effective cold smoke seasoning requires slow, even smoke distribution and proper ventilation to prevent sogginess or bitterness. Using a dedicated cold smoke generator or modifying an existing smoker ensures precise temperature control, enhancing the curing process while intensifying the flavor profile.

Flavor Profiles: Oven Seasoning vs Cold Smoke Seasoning

| Method | Flavor Profile |

|---|---|

| Oven Seasoning | Delivers a rich, roasted flavor with enhanced caramelization and depth, intensifying savory notes. |

| Cold Smoke Seasoning | Imparts a delicate, smoky aroma with subtle woody and herbal undertones, preserving natural moisture and texture. |

Equipment Needed for Each Seasoning Method

What equipment is essential for oven seasoning compared to cold smoke seasoning in curing? Oven seasoning requires a temperature-controlled oven or smoker capable of maintaining consistent heat, along with racks or trays for even airflow. Cold smoke seasoning involves a cold smoke generator, a separate smoke chamber or cool smoking box, and ventilation to ensure smoke circulates without raising the temperature above 90degF (32degC).

Health and Safety Considerations for Oven and Cold Smoke Seasoning

Oven seasoning ensures thorough cooking at high temperatures, effectively killing harmful bacteria and reducing foodborne illness risks. Cold smoke seasoning imparts flavor at low temperatures, which may not eliminate all pathogens, requiring strict hygiene and curing time controls.

- Oven Seasoning Kills Pathogens - High heat in oven seasoning destroys bacteria and parasites, enhancing safety.

- Cold Smoke Requires Careful Monitoring - Lower temperatures in cold smoking risk bacterial survival, demanding precise curing and storage.

- Health Risks Differ - Oven cooking generally reduces contamination threats more reliably than cold smoking methods.

Choosing the appropriate seasoning method depends on balancing flavor preferences with stringent health and safety protocols.

Related Important Terms

Low-temp oven activation

Low-temp oven activation in curing enhances seasoning absorption by gently opening meat fibers, resulting in a uniform and deep flavor penetration compared to cold smoke seasoning, which imparts surface-level smokiness without heat-induced texture changes. Oven seasoning ensures efficient curing through controlled warmth, accelerating enzymatic reactions and improving preservative efficacy.

Smoke-adhesion index

Oven seasoning enhances smoke-adhesion index by creating a heat-induced surface that better binds smoke particles, resulting in a more uniform and deeper flavor penetration during curing. Cold smoke seasoning, while preserving the raw texture, yields a lower smoke-adhesion index due to the absence of heat, often requiring prolonged exposure to achieve significant smoke absorption.

Cold smoke pellicle formation

Cold smoke seasoning enhances pellicle formation by drying the surface of the meat, which allows smoke particles to better adhere during curing, resulting in a more intense flavor and improved texture. Oven seasoning lacks this drying effect, often producing a less pronounced pellicle and a milder smoky taste in the final cured product.

Thermal Maillard pre-curing

Oven seasoning leverages thermal Maillard reactions by applying controlled heat, enhancing the flavor complexity and color through protein and sugar interactions during pre-curing. Cold smoke seasoning imparts smoky aroma without heat, preserving raw textures but lacking Maillard-induced flavor development essential for advanced curing stages.

Osmotic smoke infusion

Oven seasoning relies on controlled heat to accelerate osmotic smoke infusion by opening the meat's pores, enhancing flavor penetration, while cold smoke seasoning uses lower temperatures to gradually infuse smoke compounds without cooking, preserving texture and moisture. Osmotic smoke infusion during cold smoke seasoning allows for a slower, deeper penetration of phenols and carbonyl compounds, crucial for curing and flavor development.

Controlled humidity roasting

Oven seasoning for curing utilizes controlled humidity roasting to ensure even moisture distribution and stable temperature, enhancing flavor penetration and texture consistency. Cold smoke seasoning relies on low-temperature smoke infusion without heat, which preserves delicate aromas but requires separate humidity control to prevent drying and uneven curing.

Enzymatic cure acceleration

Oven seasoning accelerates enzymatic curing by providing consistent heat that enhances enzyme activity, speeding protein breakdown and flavor development. Cold smoke seasoning, operating at lower temperatures, slows enzymatic reactions but adds smoky compounds that complement the curing process without denaturing enzymes.

Smoke spirit volatilization

Oven seasoning enhances curing by uniformly volatilizing smoke spirits through controlled heat, promoting deeper flavor penetration and efficient antimicrobial effects. Cold smoke seasoning releases smoke spirits at lower temperatures, preserving delicate flavor compounds but resulting in slower volatilization and less intense curing characteristics.

Hybrid temper-smoke seasoning

Hybrid temper-smoke seasoning combines oven seasoning's controlled heat application at 50-60degC with cold smoke seasoning's low-temperature smoke infusion below 30degC, optimizing flavor development and curing efficiency. This method enhances meat preservation by balancing enzymatic activity and smoke compound absorption, resulting in superior texture and enhanced shelf-life.

Oven seasoning vs cold smoke seasoning for curing. Infographic

cookingdiff.com

cookingdiff.com