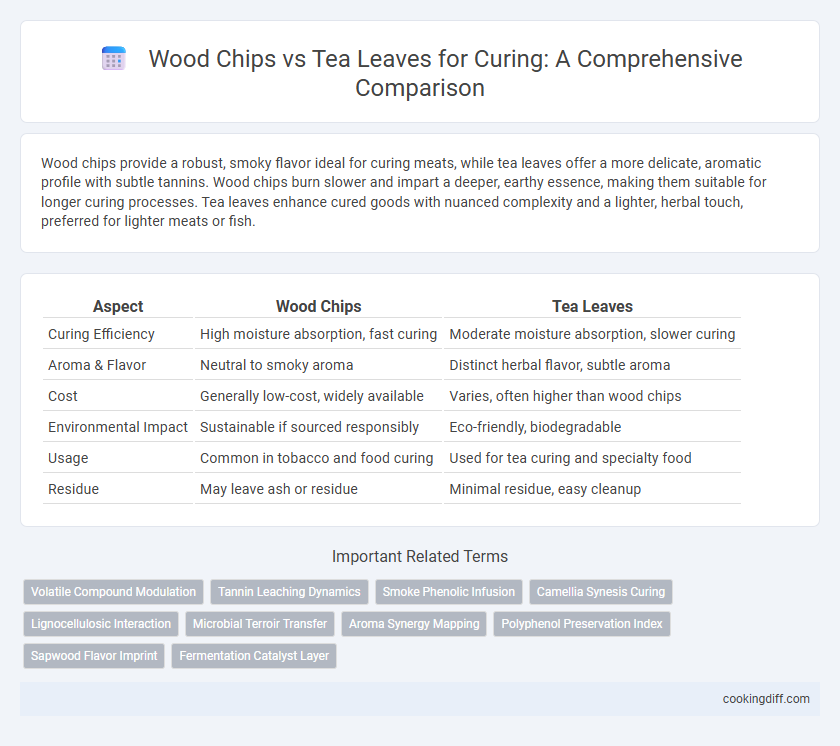

Wood chips provide a robust, smoky flavor ideal for curing meats, while tea leaves offer a more delicate, aromatic profile with subtle tannins. Wood chips burn slower and impart a deeper, earthy essence, making them suitable for longer curing processes. Tea leaves enhance cured goods with nuanced complexity and a lighter, herbal touch, preferred for lighter meats or fish.

Table of Comparison

| Aspect | Wood Chips | Tea Leaves |

|---|---|---|

| Curing Efficiency | High moisture absorption, fast curing | Moderate moisture absorption, slower curing |

| Aroma & Flavor | Neutral to smoky aroma | Distinct herbal flavor, subtle aroma |

| Cost | Generally low-cost, widely available | Varies, often higher than wood chips |

| Environmental Impact | Sustainable if sourced responsibly | Eco-friendly, biodegradable |

| Usage | Common in tobacco and food curing | Used for tea curing and specialty food |

| Residue | May leave ash or residue | Minimal residue, easy cleanup |

Understanding the Basics of Curing: Wood Chips vs Tea Leaves

Wood chips and tea leaves are commonly used natural materials in curing processes, each imparting distinct flavors and aromas to the product. Understanding their basic properties helps optimize curing outcomes based on desired characteristics and application methods.

- Wood Chips Release Smoke Compounds - Wood chips emit phenols and carbonyls during combustion, contributing smoky flavors and antibacterial properties to cured items.

- Tea Leaves Impart Herbal Notes - Tea leaves release tannins and natural oils that provide subtle, earthy, and slightly bitter tones during curing.

- Moisture Content and Combustion - Wood chips typically burn longer and hotter due to low moisture, whereas tea leaves burn quickly, affecting curing time and intensity.

Flavor Profiles: How Wood Chips and Tea Leaves Differ

| Flavor Profile | Wood Chips | Tea Leaves |

|---|---|---|

| Aroma | Imparts a rich, smoky scent with earthy undertones, varying by wood type (e.g., hickory, mesquite). | Offers a subtle, fragrant aroma with hints of floral, grassy, or herbal notes depending on the tea variety. |

| Taste | Develops bold, robust flavors that enhance savoriness and add complexity, often with sweet, caramelized notes from the smoke. | Delivers delicate, nuanced flavors ranging from slightly astringent to sweet and floral, complementing rather than overpowering the cured product. |

| Intensity | Strong and pronounced, ideal for traditional smoked meats and foods requiring deep smoky essence. | Mild and refined, suitable for lighter curing processes and infusions emphasizing aromatic subtleties. |

Traditional Uses of Wood Chips and Tea Leaves in Curing

How do traditional uses of wood chips compare to tea leaves in curing processes? Wood chips are commonly employed in smoking meats, imparting rich, smoky flavors through slow combustion, essential in barbecue and preservation techniques. Tea leaves provide a gentler curing method, often used in marinating and flavoring to infuse subtle, aromatic notes without overpowering the natural taste of the food.

Smoke and Aroma: Comparing Effects in Food Curing

Wood chips emit a robust, smoky aroma rich in phenols and guaiacol compounds that deeply infuse food with traditional barbecue flavors during curing. Tea leaves release a lighter, more delicate aroma with subtle floral and grassy notes, contributing a unique aromatic profile but less intense smoke penetration.

Smoke from wood chips enhances savory depth and complexity, ideal for meats requiring strong flavor infusion, while tea leaves impart a mild, slightly sweet fragrance best suited for delicate foods like fish. The phenolic content in wood smoke provides antimicrobial benefits, whereas tea smoke offers antioxidant properties, influencing both flavor and preservation qualities in cured foods.

Health and Safety Considerations: Wood Chips vs Tea Leaves

Wood chips used for curing often release phenolic compounds that can pose respiratory risks if proper ventilation is not maintained, while tea leaves generally emit fewer harmful volatile organic compounds, making them a safer choice. The combustion of wood chips produces higher levels of particulate matter and polycyclic aromatic hydrocarbons (PAHs), which are associated with carcinogenic effects, whereas tea leaves generate lower concentrations of these toxins. Proper handling and storage of both materials are essential to prevent mold growth and contamination, but tea leaves typically have a reduced risk of harboring harmful microbes compared to moist wood chips.

Suitability for Different Foods: Meat, Fish, and Beyond

Wood chips impart a smoky flavor ideal for curing meats, while tea leaves provide a subtle, earthy aroma suitable for curing fish and delicate foods. Both materials enhance preservation but differ in flavor intensity and food compatibility.

- Wood chips for meat - Rich smoke compounds penetrate deeply, complementing robust meats like beef and pork.

- Tea leaves for fish - Mild tannins and antioxidants reduce fishiness and add nuanced herbal notes.

- Versatility beyond - Tea leaves suit curing vegetables and poultry for lighter flavor profiles.

Choosing between wood chips and tea leaves depends on desired flavor strength and specific food characteristics.

Ease of Use: Preparation and Application Methods

Wood chips require soaking and careful temperature control before use, making preparation more involved than tea leaves. Tea leaves can be applied directly or brewed with minimal setup, offering greater ease in both preparation and application.

- Wood chips soaking - Wood chips must be soaked for at least 30 minutes to ensure consistent smoke generation during curing.

- Tea leaves direct use - Tea leaves can be sprinkled or brewed directly without extensive preparation, streamlining the curing process.

- Application method - Wood chips often require specialized smoking equipment, whereas tea leaves are adaptable to simpler methods like infusions or wraps.

Environmental Impact of Wood Chips and Tea Leaves

Wood chips typically contribute to deforestation and habitat loss when sourced unsustainably, leading to higher carbon emissions compared to tea leaves. Tea leaves, often considered an agricultural byproduct, offer a more environmentally friendly option by reducing waste and promoting circular economy practices. The biodegradability of tea leaves also results in lower soil and water pollution during the curing process compared to wood chips.

Cost and Accessibility: Which is More Practical?

Wood chips are generally more cost-effective and widely accessible compared to tea leaves, making them a practical choice for large-scale curing processes. Their consistent availability and lower price point allow industries to maintain steady operations without frequent supply disruptions.

Tea leaves, while offering unique aromatic qualities, tend to be more expensive and less accessible, especially in large quantities required for commercial curing. This limits their practicality to niche or artisanal applications where cost is less of a constraint.

Related Important Terms

Volatile Compound Modulation

Wood chips enhance curing by releasing rich phenolic compounds that deeply modulate volatile profiles, imparting smoky, earthy aromas, while tea leaves contribute unique flavonoids and tannins that subtly adjust volatile complexity with herbal and floral notes. The choice between wood chips and tea leaves significantly influences the chemical interaction during curing, affecting flavor intensity, aroma retention, and the stability of key volatiles in the final product.

Tannin Leaching Dynamics

Wood chips contain high levels of condensed tannins that leach gradually during curing, providing a slow and sustained release of polyphenols which enhances flavor development. In contrast, tea leaves release hydrolyzable tannins more rapidly, resulting in a quicker tannin leaching process that impacts the curing profile and final antioxidant properties.

Smoke Phenolic Infusion

Wood chips produce a stronger smoke phenolic infusion, rich in guaiacol and syringol compounds, which impart intense smoky flavors and antimicrobial properties during curing. Tea leaves offer a subtler phenolic profile with catechins contributing mild antioxidant effects but lack the robust smoky aroma of wood chip smoke phenols.

Camellia Synesis Curing

Camellia sinensis curing using wood chips imparts a smoky aroma and slower fermentation ideal for traditional tea profiles, whereas tea leaves curing enhances the natural grassy and floral notes through enzymatic oxidation. Wood chip curing typically involves controlled heat and airflow to influence polyphenol transformation, while leaf curing relies on ambient moisture and temperature to develop catechins and theaflavins unique to Camellia sinensis.

Lignocellulosic Interaction

Wood chips exhibit a higher lignin content compared to tea leaves, enhancing the lignocellulosic interaction during curing by providing a more robust matrix that facilitates efficient moisture regulation and aroma retention. Tea leaves, with their greater cellulose and hemicellulose composition, promote a faster degradation process, influencing the chemical changes and flavor profile differently than wood chips in curing applications.

Microbial Terroir Transfer

Wood chips provide a robust microbial terroir transfer during curing, introducing diverse bacterial and fungal communities that enhance flavor complexity and fermentation stability. Tea leaves, with their unique microbial profiles, offer subtle aromatic influences and bioactive compounds but generally result in a less pronounced microbial transfer compared to wood chips.

Aroma Synergy Mapping

Wood chips produce a robust, earthy aroma rich in phenolic and smoky notes, while tea leaves release delicate, floral, and grassy aromas containing camellia-based compounds. Aroma Synergy Mapping reveals that combining wood chips and tea leaves can create a balanced, complex fragrance profile by harmonizing their complementary volatile organic compounds.

Polyphenol Preservation Index

Wood chips exhibit a higher Polyphenol Preservation Index compared to tea leaves, enabling more effective retention of antioxidant compounds during curing. This enhanced polyphenol preservation contributes to better flavor stability and prolonged shelf life in cured products.

Sapwood Flavor Imprint

Wood chips impart a stronger sapwood flavor imprint during curing, enhancing the earthy and resinous notes commonly sought in smoked products. Tea leaves, while offering a subtler and more aromatic profile, result in a milder sapwood flavor imprint, preserving delicate herbal nuances without overpowering the natural taste.

Wood chips vs tea leaves for curing. Infographic

cookingdiff.com

cookingdiff.com