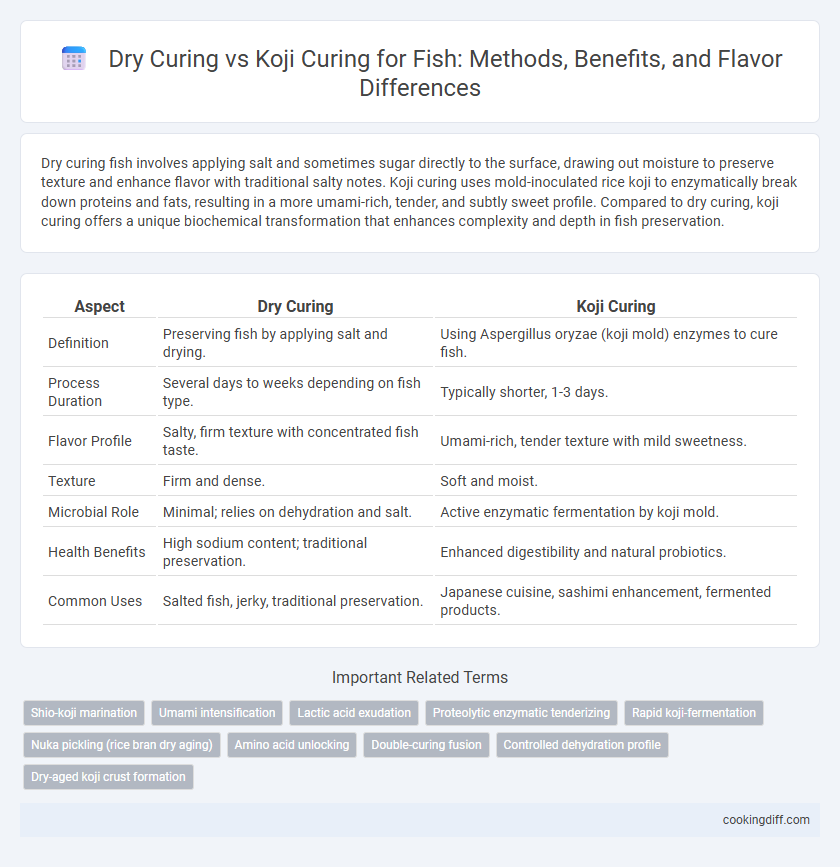

Dry curing fish involves applying salt and sometimes sugar directly to the surface, drawing out moisture to preserve texture and enhance flavor with traditional salty notes. Koji curing uses mold-inoculated rice koji to enzymatically break down proteins and fats, resulting in a more umami-rich, tender, and subtly sweet profile. Compared to dry curing, koji curing offers a unique biochemical transformation that enhances complexity and depth in fish preservation.

Table of Comparison

| Aspect | Dry Curing | Koji Curing |

|---|---|---|

| Definition | Preserving fish by applying salt and drying. | Using Aspergillus oryzae (koji mold) enzymes to cure fish. |

| Process Duration | Several days to weeks depending on fish type. | Typically shorter, 1-3 days. |

| Flavor Profile | Salty, firm texture with concentrated fish taste. | Umami-rich, tender texture with mild sweetness. |

| Texture | Firm and dense. | Soft and moist. |

| Microbial Role | Minimal; relies on dehydration and salt. | Active enzymatic fermentation by koji mold. |

| Health Benefits | High sodium content; traditional preservation. | Enhanced digestibility and natural probiotics. |

| Common Uses | Salted fish, jerky, traditional preservation. | Japanese cuisine, sashimi enhancement, fermented products. |

Introduction to Fish Curing Methods

Dry curing and koji curing are two distinct fish preservation methods. Dry curing uses salt to draw out moisture, enhancing flavor and texture.

Koji curing employs Aspergillus oryzae mold to enzymatically break down proteins and fats, creating a unique umami profile. This method accelerates fermentation, resulting in tender, deeply flavored fish. Both techniques improve shelf life while offering diverse taste experiences.

What Is Dry Curing?

Dry curing is a traditional preservation method where fish is coated with a mixture of salt and sugar, drawing out moisture to inhibit bacterial growth. This technique enhances flavor concentration and texture by slowly dehydrating the fish surface.

- Moisture Reduction - Salt in dry curing extracts water from fish tissue, preventing spoilage.

- Flavor Enhancement - The salt and sugar blend develops a rich umami and slightly sweet taste.

- Texture Improvement - Dry curing firms the fish by tightening its muscle fibers through dehydration.

What Is Koji Curing?

Koji curing utilizes the mold Aspergillus oryzae, which produces enzymes that break down fish proteins and fats, enhancing umami and tenderness. Unlike traditional dry curing, koji curing accelerates the curing process and imparts a distinct savory flavor profile.

This method allows for precise control over texture and taste by adjusting fermentation time and koji application. Koji curing also reduces salt content while preserving fish freshness, making it a popular choice for modern seafood preparations.

Key Differences: Dry Curing vs Koji Curing

What are the key differences between dry curing and koji curing for fish? Dry curing uses salt to draw out moisture and preserve fish, creating a firm texture and intense flavor. Koji curing employs Aspergillus oryzae mold to break down proteins and fats, resulting in a tender texture and umami-rich taste.

Flavor Development in Dry and Koji Curing

| Dry curing | Enhances fish flavor through salt absorption and dehydration, intensifying natural umami and firming texture; enzymatic reactions develop complex, savory notes over time. |

| Koji curing | Utilizes Aspergillus oryzae enzymes to break down proteins into amino acids, significantly boosting sweetness and umami; imparts a subtly fermented, aromatic depth distinct from traditional methods. |

Texture Changes: Dry Curing vs Koji Curing

Dry curing fish results in a firmer texture due to moisture loss and protein denaturation, creating a dense and chewy consistency. Koji curing utilizes enzymes from Aspergillus oryzae to break down proteins and fats, leading to a tender and umami-rich texture. The enzymatic activity in koji curing produces a softer, more delicate mouthfeel compared to the toughened texture of dry-cured fish.

Safety and Shelf Life Considerations

Dry curing fish relies on salt to inhibit bacterial growth and extend shelf life, effectively reducing moisture content to prevent spoilage. Koji curing employs enzymatic fermentation from Aspergillus oryzae, enhancing safety by breaking down proteins and sugars while promoting beneficial microbes that inhibit pathogens.

- Dry curing safety - Salt concentration must be carefully controlled to prevent harmful bacterial proliferation, such as Clostridium botulinum.

- Koji curing shelf life - The fermentation process can extend shelf life by producing organic acids that preserve fish naturally.

- Environmental factors - Temperature and humidity critically affect both curing methods, influencing microbial activity and spoilage rates.

Nutritional Impact of Each Curing Method

Dry curing fish enhances protein concentration by reducing moisture content while preserving essential omega-3 fatty acids, contributing to improved nutritional density. Koji curing employs enzymatic fermentation, increasing amino acid profiles and bioavailability of nutrients such as peptides and vitamins, particularly B-complex vitamins. Nutritionally, koji curing may offer superior antioxidant properties and digestibility compared to the traditional dry curing process.

Best Types of Fish for Dry and Koji Curing

Dry curing and koji curing enhance fish flavor through distinct enzymatic processes, suited to different fish types. Fatty fish like salmon excel in dry curing, while white fish such as cod benefit from koji curing's delicate enzymatic action.

- Salmon (Dry Curing) - Rich oil content allows for deep flavor penetration and firm texture after dry curing.

- Cod (Koji Curing) - Mild flavor and lean flesh absorb koji enzymes well, resulting in tender, umami-rich fish.

- Mackerel (Dry Curing) - Dense, oily flesh withstands the salt draw of dry curing, enhancing its robust taste.

Choosing the right curing method optimizes texture and flavor according to the fish species' fat content and muscle structure.

Related Important Terms

Shio-koji marination

Shio-koji marination combines salt with koji mold enzymes to tenderize and enhance umami in fish more naturally than traditional dry curing, which relies solely on salt to dehydrate and preserve. This method accelerates protein breakdown and flavor development, resulting in a moist texture and complex taste profile while maintaining optimal preservation.

Umami intensification

Dry curing enhances fish umami by concentrating natural glutamates through salt-driven moisture reduction, intensifying savory flavors. Koji curing employs Aspergillus oryzae enzymes to break down proteins into amino acids, significantly boosting umami compounds like glutamic acid and enhancing taste complexity.

Lactic acid exudation

Dry curing of fish relies on salt-induced dehydration which limits lactic acid exudation, preserving texture and flavor differently compared to koji curing that employs Aspergillus oryzae enzymes to promote higher lactic acid production, enhancing umami and tenderizing the flesh through controlled fermentation. The increased lactic acid exudation in koji curing contributes to a distinct tangy profile and improved preservation by lowering pH more effectively than traditional dry curing methods.

Proteolytic enzymatic tenderizing

Dry curing uses salt to dehydrate and preserve fish, relying minimally on enzymatic activity for tenderizing, whereas koji curing involves Aspergillus oryzae enzymes that break down proteins through proteolytic activity, resulting in enhanced tenderization and flavor development. The proteolytic enzymes in koji curing accelerate the breakdown of muscle proteins, producing a more delicate texture compared to the firmer outcome of dry curing.

Rapid koji-fermentation

Rapid koji-fermentation accelerates the enzymatic breakdown of fish proteins, enhancing flavor development and tenderness compared to traditional dry curing methods. This innovative approach reduces curing time while maintaining moisture and promoting umami-rich compounds, resulting in a superior taste profile.

Nuka pickling (rice bran dry aging)

Nuka pickling, a traditional Japanese dry curing method using fermented rice bran, enhances fish flavor by promoting enzymatic breakdown and delicate nutrient preservation compared to koji curing, which primarily utilizes Aspergillus oryzae mold to introduce unique umami profiles through microbial fermentation. The dry aging in nuka creates a controlled environment that intensifies texture and aroma without excess moisture, distinguishing it from the moist fermentation characteristics of koji curing in fish preservation.

Amino acid unlocking

Dry curing enhances fish flavor by concentrating amino acids through salt-induced dehydration, promoting enzymatic breakdown that releases free amino acids responsible for umami taste. Koji curing utilizes Aspergillus oryzae enzymes to accelerate proteolysis, unlocking a wider range of amino acids and peptides, resulting in a more complex and savory flavor profile.

Double-curing fusion

Double-curing fusion combines dry curing's salt-driven dehydration with koji curing's enzymatic fermentation, producing fish with enhanced umami and complex texture. This method leverages koji mold's proteolytic enzymes to tenderize the fish while salt in dry curing intensifies flavor and preserves, resulting in superior taste and shelf life.

Controlled dehydration profile

Dry curing for fish involves controlled dehydration through salt application, which draws moisture out gradually to enhance texture and preserve flavor, while koji curing employs enzymatic activity from Aspergillus oryzae to break down proteins and fats, resulting in a unique tenderization and umami development without significant moisture loss. The controlled dehydration profile in dry curing offers precise preservation and texture control, whereas koji curing balances enzymatic softening with mild moisture retention, creating distinct sensory attributes.

Dry curing vs koji curing for fish. Infographic

cookingdiff.com

cookingdiff.com