Wooden smoking boxes provide a traditional method for curing with natural smoky flavors, allowing for better absorption and a rustic aroma. Electric cold smoke generators offer precise temperature control and consistent smoke production, making them ideal for extended curing processes without overheating the product. Choosing between the two depends on whether you prioritize authentic flavor nuances or modern efficiency in your curing process.

Table of Comparison

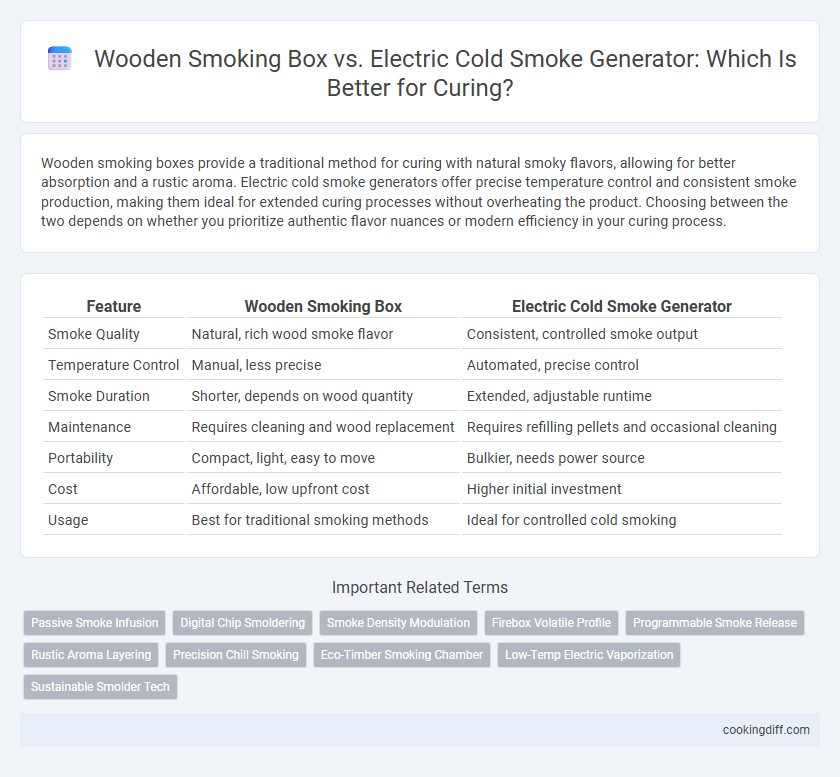

| Feature | Wooden Smoking Box | Electric Cold Smoke Generator |

|---|---|---|

| Smoke Quality | Natural, rich wood smoke flavor | Consistent, controlled smoke output |

| Temperature Control | Manual, less precise | Automated, precise control |

| Smoke Duration | Shorter, depends on wood quantity | Extended, adjustable runtime |

| Maintenance | Requires cleaning and wood replacement | Requires refilling pellets and occasional cleaning |

| Portability | Compact, light, easy to move | Bulkier, needs power source |

| Cost | Affordable, low upfront cost | Higher initial investment |

| Usage | Best for traditional smoking methods | Ideal for controlled cold smoking |

Introduction to Curing: Traditional vs Modern Methods

| Method | Description | Advantages | Disadvantages |

|---|---|---|---|

| Wooden Smoking Box | Traditional curing method using natural wood smoke to preserve and flavor meats. | Enhances natural smoky flavor; simple setup with authentic results. | Temperature control is less precise; time-consuming process prone to inconsistencies. |

| Electric Cold Smoke Generator | Modern device producing cold smoke at controlled temperatures for curing and flavoring. | Precise temperature and smoke output control; consistent curing results; safer and cleaner operation. | Requires electricity and initial investment; may lack some traditional smoky nuances. |

Overview of Wooden Smoking Boxes

What are the key features of wooden smoking boxes used for curing? Wooden smoking boxes provide a natural, traditional method for infusing smoke flavor and preserving meats and fish through slow, controlled exposure to smoke. These boxes allow for consistent airflow and temperature regulation, enhancing the curing process with an authentic wood-smoke aroma.

Features and Benefits of Electric Cold Smoke Generators

Electric cold smoke generators offer precise temperature control and consistent smoke output, essential for delicate curing processes that prevent overheating or drying out the product. Their compact design and easy operation enable efficient cold smoking indoors or in controlled environments without the need for large wood boxes. With adjustable smoke intensity and longer run times, these generators enhance flavor infusion and maintain product quality, making them ideal for professional and home curing applications.

Smoke Flavor Profiles: Wood vs Electricity

Wooden smoking boxes produce rich, complex smoke flavor profiles influenced by the type of wood used, offering deep, natural aromas for curing. Electric cold smoke generators deliver a cleaner, more controlled smoke with less intensity, allowing precise flavor customization without overpowering the product.

- Wood smoke intensity - The burning wood releases a variety of organic compounds creating robust and nuanced flavors in cured foods.

- Electric smoke consistency - Electricity generates consistent smoke output, ensuring uniform curing conditions and mild taste profiles.

- Flavor customization - Wooden boxes allow experimentation with different wood species, while electric units rely on wood chips or pellets to adjust flavor strength.

Choosing between wooden smoking boxes and electric cold smoke generators depends on desired smoke character and control level during curing.

Ease of Use and Setup Comparison

Wooden smoking boxes offer a traditional curing method that requires manual setup and consistent monitoring to maintain optimal smoke levels, making them less convenient for beginners. In contrast, electric cold smoke generators provide a user-friendly experience with automated smoke production and adjustable settings, simplifying the curing process. This ease of use and quick setup make electric cold smoke generators ideal for efficient and precise curing.

Temperature and Smoke Control Capabilities

Wooden smoking boxes offer traditional temperature control through manual adjustments and rely heavily on skilled monitoring, which can lead to fluctuating heat levels during curing. Electric cold smoke generators provide precise temperature regulation with built-in thermostats, ensuring consistent low temperatures ideal for curing meats and cheeses.

Electric models allow fine-tuned smoke density adjustments, enhancing flavor profiles while maintaining safety standards. Wooden boxes may produce richer smoke flavors due to natural wood combustion but lack the exact smoke output control of electric generators. For consistent, controlled curing, electric cold smoke generators are generally preferred in professional settings.

Maintenance and Cleaning Requirements

Wooden smoking boxes demand regular cleaning to remove creosote buildup and ash, which can affect flavor and safety. Electric cold smoke generators require less frequent maintenance, primarily focusing on residue removal from the ceramic element and periodic checks of the electrical components.

- Wooden Box Residue - Creosote and tar accumulate quickly, necessitating thorough scraping and washing after each use.

- Electric Generator Cleaning - The ceramic element needs gentle brushing to prevent clogging and ensure consistent smoke production.

- Component Inspection - Electrical wiring and connections should be inspected regularly to avoid malfunctions and maintain safety standards.

Cost Analysis: Wooden Boxes vs Electric Generators

Wooden smoking boxes typically offer a lower initial purchase price but require more manual labor and maintenance costs over time. Electric cold smoke generators have higher upfront costs but provide consistent temperature control and lower long-term operational expenses.

- Initial Investment - Wooden boxes are generally less expensive to buy compared to electric smoke generators, making them accessible for small-scale curing.

- Maintenance Costs - Wooden boxes demand frequent maintenance such as wood treatment and repairs, increasing overall expenses.

- Operational Efficiency - Electric cold smoke generators consume electricity but reduce labor costs and provide precise smoke output control, optimizing curing processes.

Suitability for Different Foods and Curing Techniques

Wooden smoking boxes excel in imparting rich, traditional smoky flavors ideal for curing meats like sausages, hams, and fish through longer, low-temperature smoking processes. Their natural wood composition enhances the depth of flavor but may lack precise temperature control, making them less suitable for delicate foods or techniques requiring consistency.

Electric cold smoke generators provide accurate temperature regulation and consistent smoke output, benefiting the curing of sensitive products like cheese, nuts, and some seafood that require cold smoking below 90degF (32degC). This precision allows for versatile curing techniques, especially those prioritizing flavor infusion without cooking the food.

Related Important Terms

Passive Smoke Infusion

Wooden smoking boxes provide a natural, passive smoke infusion by slowly releasing aromatic wood smoke that penetrates meats or fish during curing, enhancing flavor complexity and texture. Electric cold smoke generators offer precise temperature control and consistent smoke output but may lack the nuanced, passive smoke absorption achieved with traditional wooden smoking boxes.

Digital Chip Smoldering

Digital chip smoldering in electric cold smoke generators offers precise temperature control and consistent smoke output, enhancing the curing process with minimal user intervention. Wooden smoking boxes, while traditional, lack this advanced regulation, resulting in less predictable smoke quality and potential temperature fluctuations during curing.

Smoke Density Modulation

Wooden smoking boxes offer natural smoke density modulation through adjustable vents and wood type selection, providing rich, authentic flavor profiles ideal for traditional curing methods. Electric cold smoke generators deliver precise, consistent smoke density control with electronic settings, enabling uniform curing processes and enhanced reproducibility for industrial applications.

Firebox Volatile Profile

Wooden smoking boxes produce a complex firebox volatile profile rich in phenols, carbonyls, and organic acids, which impart distinct smoky flavors essential for traditional curing techniques. Electric cold smoke generators emit a more controlled and consistent volatile profile with lower levels of harmful compounds, making them ideal for precise flavor development and safer indoor use during the curing process.

Programmable Smoke Release

Wooden smoking boxes offer a traditional curing method with limited control over smoke release, relying on manual adjustments for smoke intensity. Electric cold smoke generators provide programmable smoke release, ensuring precise, consistent smoke flow and enhanced control over flavor development during the curing process.

Rustic Aroma Layering

Wooden smoking boxes infuse curing meats with deep, complex rustic aroma layering by releasing natural wood smoke that penetrates evenly, enhancing flavor profiles through traditional slow-smoking techniques. Electric cold smoke generators offer precise temperature control and consistent smoke output but may lack the nuanced, multi-dimensional rustic aroma achieved through authentic wood combustion.

Precision Chill Smoking

Wooden smoking boxes offer traditional aroma infusion but lack the temperature control and smoke density precision essential for optimal curing, whereas electric cold smoke generators provide consistent and adjustable chilling smoke output, enhancing flavor development without overheating the meat. Precision chill smoking with electric devices allows for meticulous control over cold smoke intensity and duration, ensuring uniform curing conditions critical for safety and taste enhancement.

Eco-Timber Smoking Chamber

The Eco-Timber Smoking Chamber combines the authentic flavor of a wooden smoking box with the precise temperature control of an electric cold smoke generator, optimizing curing processes for meats and cheeses. Its sustainable timber construction enhances smoke infusion while reducing environmental impact compared to traditional metal generators, making it ideal for eco-conscious culinary curing.

Low-Temp Electric Vaporization

Low-temp electric vaporization in electric cold smoke generators offers precise temperature control, ensuring consistent smoke output below 90degF, which enhances curing by preserving delicate flavors and preventing moisture buildup. Wooden smoking boxes rely on traditional smoldering wood chips, which can cause temperature fluctuations and uneven smoke density, potentially compromising the curing process.

Wooden Smoking Box vs Electric Cold Smoke Generator for Curing. Infographic

cookingdiff.com

cookingdiff.com