Air drying hams allows for a natural, gradual moisture loss that enhances flavor complexity and subtle aroma development. Chamber aging provides precise control over temperature and humidity, reducing the risk of spoilage and ensuring consistent texture and safety. Both methods influence the final taste profile, with air drying offering traditional character and chamber aging delivering uniform quality.

Table of Comparison

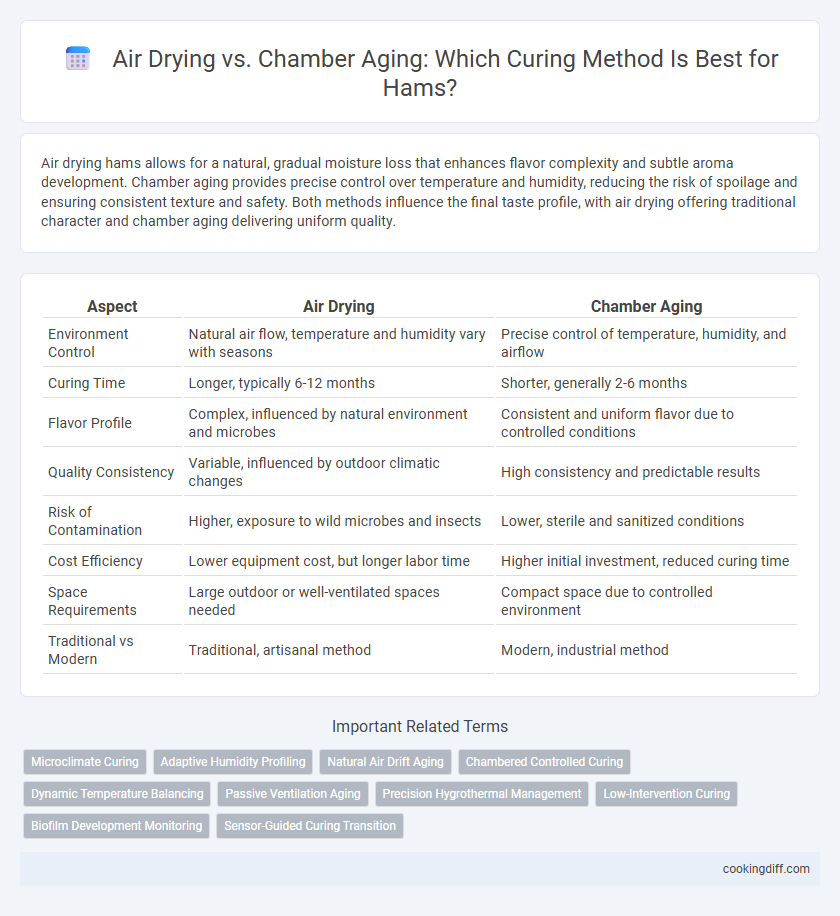

| Aspect | Air Drying | Chamber Aging |

|---|---|---|

| Environment Control | Natural air flow, temperature and humidity vary with seasons | Precise control of temperature, humidity, and airflow |

| Curing Time | Longer, typically 6-12 months | Shorter, generally 2-6 months |

| Flavor Profile | Complex, influenced by natural environment and microbes | Consistent and uniform flavor due to controlled conditions |

| Quality Consistency | Variable, influenced by outdoor climatic changes | High consistency and predictable results |

| Risk of Contamination | Higher, exposure to wild microbes and insects | Lower, sterile and sanitized conditions |

| Cost Efficiency | Lower equipment cost, but longer labor time | Higher initial investment, reduced curing time |

| Space Requirements | Large outdoor or well-ventilated spaces needed | Compact space due to controlled environment |

| Traditional vs Modern | Traditional, artisanal method | Modern, industrial method |

Introduction to Ham Curing Methods

| Air drying | Traditional method involving hanging hams in controlled temperature and humidity environments for several months, promoting natural moisture loss and flavor development. |

| Chamber aging | Modern technique using specialized chambers with precisely regulated temperature, humidity, and airflow to accelerate curing while maintaining safety and consistency. |

| Introduction to Ham Curing Methods | Ham curing relies on two primary approaches: air drying, which enhances texture and taste via slow dehydration; and chamber aging, which offers controlled conditions to optimize curing time and product quality. |

What is Air Drying Ham?

Air drying ham involves hanging the meat in a controlled environment with natural airflow, allowing moisture to evaporate slowly over time. This traditional curing method enhances the ham's flavor and texture by promoting enzymatic and microbial activity without mechanical intervention. Unlike chamber aging, air drying relies on ambient conditions like temperature, humidity, and ventilation to develop the ham's distinctive aroma and taste.

The Chamber Aging Process Explained

The chamber aging process for hams involves carefully controlled temperature and humidity settings to promote even curing and develop complex flavors. Unlike air drying, chamber aging minimizes contamination risks and allows precise monitoring of microbial activity essential for texture enhancement. This method accelerates maturation while preserving moisture levels, resulting in consistently tender and flavorful hams.

Key Differences Between Air Drying and Chamber Aging

Air drying involves hanging hams in a controlled natural environment with variable temperature and humidity, promoting slow moisture loss and flavor development over weeks or months. Chamber aging uses a precisely regulated enclosure to maintain consistent conditions, accelerating curing while reducing contamination risks.

Air drying allows hams to develop complex, nuanced flavors influenced by ambient environmental factors, often resulting in a more traditional taste and texture profile. Chamber aging optimizes microbial activity and enzymatic reactions through strict control of temperature, humidity, and airflow, producing uniform product quality. The choice between methods affects curing time, flavor intensity, texture, and food safety in ham production.

Flavor Profiles: Air-Dried vs Chamber-Aged Hams

Air-dried hams develop complex, robust flavor profiles through natural dehydration and slow enzymatic reactions, resulting in a richer, nuttier taste with subtle earthy undertones. This traditional method enhances the ham's texture by promoting a firmer, drier consistency favored in artisanal cured meats.

Chamber-aged hams offer precise control over temperature and humidity, yielding consistently delicate and nuanced flavors with balanced saltiness and mild sweetness. The controlled environment accelerates curing, producing a softer texture and preserving moisture for a tender bite.

Texture and Appearance Comparisons

Air drying hams results in a firmer texture with a natural, matte finish, while chamber aging produces a softer interior with a glossy, uniform surface. The controlled environment in chamber aging enhances moisture retention, impacting both the texture and sheen of the ham.

- Air drying creates a denser texture - Prolonged exposure to air reduces moisture, firming the ham's muscle fibers.

- Chamber aging yields a tender texture - Regulated humidity and temperature preserve juiciness and softness.

- Appearance varies by method - Air drying develops a rustic, matte exterior, whereas chamber aging results in a smooth, glossy finish.

Equipment and Space Requirements

Air drying hams requires minimal equipment but significant open space with controlled temperature and humidity, making it more dependent on natural environmental conditions. Chamber aging demands specialized, airtight chambers equipped with precise climate control systems, enabling consistent curing regardless of external weather fluctuations.

- Air drying requires large, ventilated spaces - Open areas must maintain stable temperature and humidity for optimal drying.

- Chamber aging needs advanced climate control equipment - Machines regulate airflow, temperature, and humidity precisely for uniform curing.

- Space efficiency differs - Chamber aging uses compact facilities while air drying relies on expansive environments.

Traditional vs Modern Curing Techniques

Traditional air drying relies on natural environmental conditions for curing hams, resulting in unique flavor profiles influenced by regional climates. Chamber aging offers controlled temperature and humidity, ensuring consistent quality and reducing curing time compared to traditional methods.

- Air Drying - Utilizes ambient airflow and seasonal weather variations to cure hams over extended periods.

- Chamber Aging - Employs precise climate control technology to replicate optimal curing conditions year-round.

- Flavor Development - Air drying produces more complex, terroir-driven flavors, while chamber aging focuses on consistency and efficiency.

Choosing between traditional air drying and modern chamber aging depends on desired flavor complexity versus production scalability.

Safety and Shelf Life Considerations

Which method offers better safety and shelf life for curing hams, air drying or chamber aging? Air drying relies on natural airflow and humidity control, reducing microbial growth and extending shelf life when properly monitored. Chamber aging provides a controlled environment that minimizes contamination risks and allows for consistent product quality and enhanced safety.

Related Important Terms

Microclimate Curing

Microclimate curing in ham production leverages controlled temperature, humidity, and airflow within chamber aging to create a precise environment that enhances flavor development and texture consistency compared to traditional air drying. Chamber aging minimizes external contaminants and moisture fluctuations, resulting in improved microbial safety and a more uniform curing process.

Adaptive Humidity Profiling

Adaptive humidity profiling in air drying balances moisture loss to prevent case hardening, enhancing flavor and texture consistency in ham curing. Chamber aging leverages controlled humidity gradients to uniformly penetrate the meat, reducing spoilage risk while optimizing enzymatic activity for superior taste development.

Natural Air Drift Aging

Natural Air Drift Aging enhances flavor and texture by allowing consistent airflow and controlled humidity, promoting gradual moisture evaporation and enzymatic activity in hams. This method contrasts with chamber aging by relying on environmental conditions to develop complex aromas and tenderization without mechanical intervention.

Chambered Controlled Curing

Chamber aging for hams utilizes precise temperature and humidity control to optimize enzymatic activity and moisture loss, resulting in consistent texture and enhanced flavor development compared to traditional air drying. This controlled curing environment minimizes contamination risks and accelerates maturation times while preserving the ham's quality and safety standards.

Dynamic Temperature Balancing

Air drying hams relies on natural airflow and ambient conditions, resulting in slower moisture loss and uneven curing, whereas chamber aging utilizes dynamic temperature balancing to maintain precise humidity and temperature levels for consistent texture and flavor development. Dynamic temperature balancing optimizes enzymatic activity and microbial growth, accelerating aging while reducing spoilage risks compared to traditional air drying methods.

Passive Ventilation Aging

Passive ventilation aging of hams relies on controlled airflow and humidity within curing chambers to enhance enzymatic development and flavor complexity, contrasting with air drying that exposes hams to variable environmental conditions often leading to inconsistent texture and taste. Chamber aging with passive ventilation ensures stable temperature and humidity, promoting uniform moisture loss and safer pathogen control essential for premium cured ham quality.

Precision Hygrothermal Management

Precision hygrothermal management in air drying allows for natural moisture evaporation and flavor development through controlled temperature and humidity cycles, enhancing the ham's texture and aroma complexity. Chamber aging utilizes advanced systems to maintain consistent hygrothermal conditions, accelerating curing times while preventing microbial growth and ensuring uniform product quality.

Low-Intervention Curing

Air drying preserves ham's natural enzymes and microbial flora, promoting complex flavor development with minimal processing, ideal for low-intervention curing methods. Chamber aging accelerates moisture loss and controls temperature and humidity, ensuring consistent texture and safety while maintaining artisanal qualities in a controlled environment.

Biofilm Development Monitoring

Air drying enables natural biofilm formation on ham surfaces, supporting microbial stability crucial for flavor development, while chamber aging allows precise environmental control to monitor and manage biofilm growth effectively using advanced sensors and imaging techniques. Continuous biofilm development monitoring in chamber aging offers optimized pathogen control and consistent product quality compared to the variable conditions of air drying.

Air drying vs Chamber aging for hams. Infographic

cookingdiff.com

cookingdiff.com