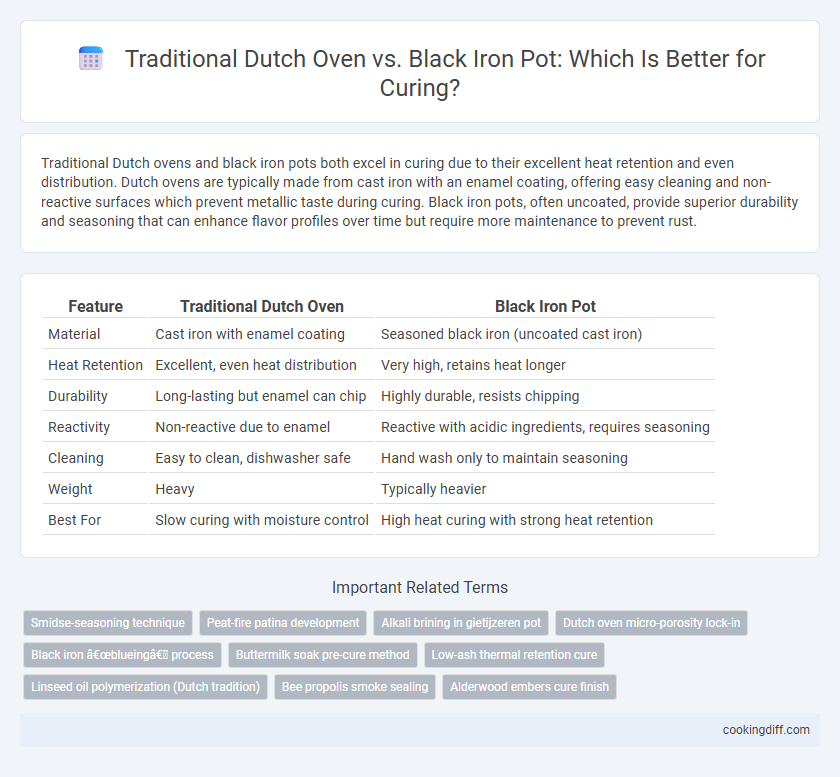

Traditional Dutch ovens and black iron pots both excel in curing due to their excellent heat retention and even distribution. Dutch ovens are typically made from cast iron with an enamel coating, offering easy cleaning and non-reactive surfaces which prevent metallic taste during curing. Black iron pots, often uncoated, provide superior durability and seasoning that can enhance flavor profiles over time but require more maintenance to prevent rust.

Table of Comparison

| Feature | Traditional Dutch Oven | Black Iron Pot |

|---|---|---|

| Material | Cast iron with enamel coating | Seasoned black iron (uncoated cast iron) |

| Heat Retention | Excellent, even heat distribution | Very high, retains heat longer |

| Durability | Long-lasting but enamel can chip | Highly durable, resists chipping |

| Reactivity | Non-reactive due to enamel | Reactive with acidic ingredients, requires seasoning |

| Cleaning | Easy to clean, dishwasher safe | Hand wash only to maintain seasoning |

| Weight | Heavy | Typically heavier |

| Best For | Slow curing with moisture control | High heat curing with strong heat retention |

Introduction to Curing: Dutch Oven vs Black Iron Pot

Curing involves preserving and enhancing flavors through controlled heat and moisture. Traditional Dutch ovens offer excellent heat retention and even distribution, making them ideal for slow curing processes.

Black iron pots provide superior durability and develop a natural non-stick surface with use, which improves flavor penetration during curing. Both vessels have unique properties that influence the texture and taste of cured foods.

Material Composition and Heat Retention

| Material Composition | Traditional Dutch ovens are typically made of cast iron coated with porcelain enamel, providing a non-reactive and smooth cooking surface, while black iron pots are made of raw, uncoated iron known for its durability and natural seasoning properties. |

|---|---|

| Heat Retention | Cast iron Dutch ovens offer excellent heat retention and even heat distribution, essential for consistent curing, whereas black iron pots heat up faster and maintain high temperatures efficiently, making them ideal for prolonged heat applications in curing processes. |

Historical Uses in Curing Methods

How have traditional Dutch ovens and black iron pots been historically used in curing processes? Traditional Dutch ovens, known for their heavy cast iron construction and tight-fitting lids, were commonly used for slow-cooking and curing meats by trapping moisture and heat evenly. Black iron pots, favored for their durability and even heat distribution, played a crucial role in fermenting and curing various foods in rustic and indigenous practices across Europe.

Flavor Impact: Dutch Oven and Black Iron Pot

The Traditional Dutch Oven evenly distributes heat, enhancing the depth of cured flavors through consistent temperature control. Black Iron Pots retain heat longer, imparting a richer, smokier taste profile ideal for slow curing processes.

- Heat Distribution - Dutch Ovens provide uniform heating, preventing hot spots that can affect flavor development.

- Heat Retention - Black Iron Pots maintain steady temperatures, allowing flavors to intensify over extended curing times.

- Flavor Impact - The cast iron material in Black Iron Pots contributes subtle smoky notes not typically found in Dutch Ovens.

Durability and Longevity Comparison

Traditional Dutch ovens are typically made from cast iron with an enamel coating, which provides excellent rust resistance but can chip over time, affecting durability. Black iron pots, made from bare carbon steel, develop a natural seasoning that enhances their non-stick properties and protects against rust when properly maintained.

In terms of longevity, enamel-coated Dutch ovens require careful handling to prevent chipping, yet they resist acidic foods better than black iron pots. Black iron pots can last decades with regular seasoning and avoid the flaking issues common to enameled surfaces, making them highly durable for curing applications.

Maintenance: Seasoning and Care for Curing

Traditional Dutch ovens require regular seasoning to maintain their non-stick surface and prevent rust, especially when used for curing. Black iron pots, while also needing seasoning, often demand more frequent care to retain their protective coating during the curing process.

- Traditional Dutch oven seasoning - Involves applying a thin layer of oil and heating it to create a durable, non-stick surface.

- Black iron pot seasoning - Requires multiple oil applications and consistent heating to build a strong, rust-resistant patina.

- Cleaning methods - Both require gentle cleaning without soap to preserve seasoning, using hot water and a brush instead.

Proper maintenance ensures longevity and optimal performance of both cookware types in curing applications.

Suitability for Different Types of Curing

Traditional Dutch ovens excel in slow curing processes like braising and stewing due to their thick cast iron construction that ensures even heat distribution. Black iron pots retain high heat effectively, making them ideal for high-temperature curing methods such as searing or caramelizing. Each pot type suits different curing techniques, with the Dutch oven best for moisture-retentive methods and the black iron pot favoring dry heat applications.

Cost and Accessibility for Home Curing

Traditional Dutch ovens tend to be more expensive and less accessible compared to black iron pots, which are budget-friendly and widely available. Black iron pots offer a cost-effective solution for home curing without compromising durability.

- Cost Efficiency - Black iron pots generally cost significantly less than traditional Dutch ovens, making them ideal for budget-conscious home curers.

- Market Availability - Black iron pots are commonly found in various retail outlets and online stores, increasing accessibility for most users.

- Durability versus Price - While Dutch ovens provide excellent heat retention, black iron pots balance durability with affordability, supporting practical home curing needs.

User Experience: Handling and Convenience

The traditional Dutch oven offers excellent heat retention and even cooking but tends to be heavier and bulkier, making it less convenient for frequent handling during curing. Black iron pots are lighter with a smoother surface, providing easier maneuverability and quicker clean-up, enhancing user convenience. Both cookware options deliver reliable curing results but differ significantly in handling ease and overall user experience.

Related Important Terms

Smidse-seasoning technique

The Smidse-seasoning technique enhances the curing process by creating a durable, non-stick surface through multiple layers of polymerized oil, ideal for both Traditional Dutch Ovens and Black Iron Pots. Black Iron Pots often achieve a more even seasoning layer with Smidse, promoting superior heat retention and consistent curing results compared to the thicker, cast-iron Dutch Oven surfaces.

Peat-fire patina development

Traditional Dutch ovens develop a unique peat-fire patina through repeated exposure to smoky, low-temperature curing conditions, enhancing their heat retention and flavor infusion properties. Black iron pots, while durable, form a less pronounced peat-fire patina, resulting in a different interaction with flavors during prolonged curing processes.

Alkali brining in gietijzeren pot

Alkali brining in a gietijzeren pot enhances curing by maintaining consistent heat distribution and superior rust resistance compared to traditional Dutch ovens, which are typically less durable under alkaline conditions. The porous nature of black iron pots allows for better moisture retention and subtle flavor development during the curing process.

Dutch oven micro-porosity lock-in

Traditional Dutch ovens offer superior curing benefits due to their micro-porosity, which allows for optimal moisture retention and gradual air exchange, enhancing flavor development and texture. In contrast, black iron pots, while durable, lack this inherent micro-porosity, resulting in less effective moisture regulation during the curing process.

Black iron “blueing” process

The black iron pot's "blueing" process forms a protective oxide layer that enhances corrosion resistance, making it ideal for curing applications requiring durability and longevity. In contrast to traditional Dutch ovens, black iron pots develop this unique patina through controlled heating, which improves seasoning retention and contributes to superior heat distribution during the curing process.

Buttermilk soak pre-cure method

The Traditional Dutch Oven, known for its thick walls and tight-fitting lid, offers excellent heat retention and even cooking, making it ideal for maintaining consistent temperatures during a buttermilk soak pre-cure method. In contrast, the Black Iron Pot provides superior heat conductivity and durability, ensuring accelerated fermentation and improved flavor infusion during the curing process.

Low-ash thermal retention cure

Traditional Dutch ovens and black iron pots both excel in low-ash thermal retention curing, but black iron pots offer superior heat distribution and maintain consistent temperatures longer due to their dense iron composition. Dutch ovens, typically made from cast iron with an enamel coating, provide good heat retention but may have higher ash content, which can slightly impact the purity of the curing environment.

Linseed oil polymerization (Dutch tradition)

Traditional Dutch ovens utilize linseed oil polymerization, a method rooted in Dutch curing practices that enhances the pot's non-stick and rust-resistant properties through natural oil oxidation and hardening. In contrast, black iron pots often lack this specialized linseed oil treatment, resulting in different seasoning characteristics and maintenance requirements.

Bee propolis smoke sealing

Traditional Dutch ovens provide moderate heat retention and even cooking, but black iron pots excel in curing with superior heat conductivity and durability. When sealing with bee propolis smoke, black iron pots enhance the infusion of natural antimicrobial properties, promoting a more effective and aromatic curing process.

Traditional Dutch Oven vs Black Iron Pot for curing. Infographic

cookingdiff.com

cookingdiff.com