Dry curing preserves meats by applying salt and sometimes sugar directly to the surface, drawing out moisture to inhibit bacterial growth and concentrate flavors. Koji curing utilizes the mold Aspergillus oryzae, which produces enzymes that break down proteins and fats, enhancing umami and tenderness in the meat. While dry curing relies on salt's dehydrating effects, koji curing combines enzymatic activity and controlled moisture for a unique, flavorful texture.

Table of Comparison

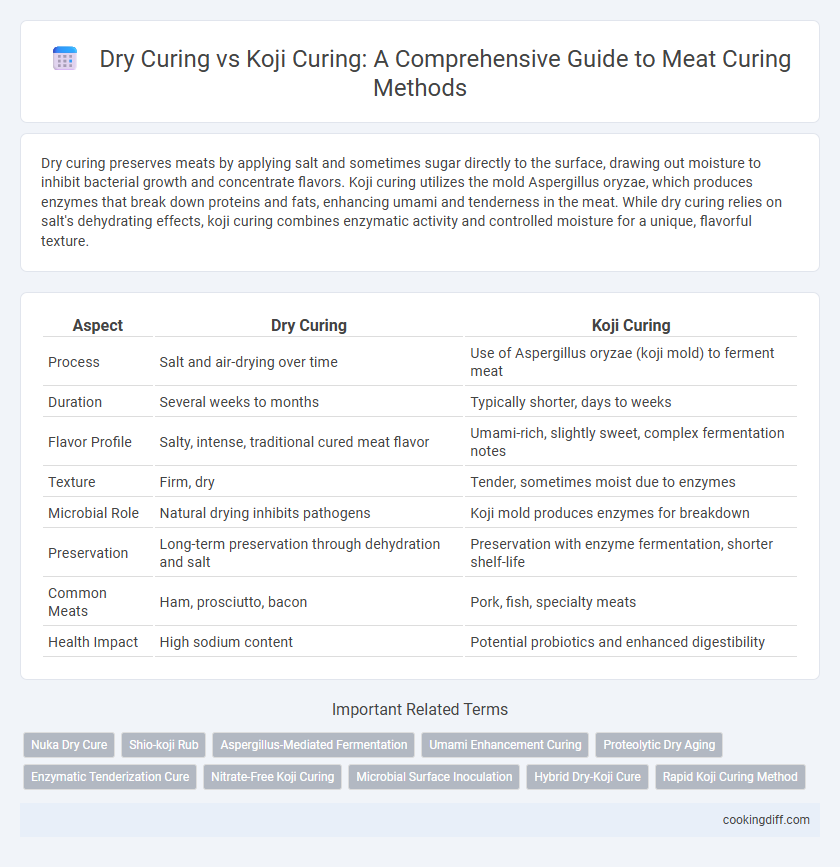

| Aspect | Dry Curing | Koji Curing |

|---|---|---|

| Process | Salt and air-drying over time | Use of Aspergillus oryzae (koji mold) to ferment meat |

| Duration | Several weeks to months | Typically shorter, days to weeks |

| Flavor Profile | Salty, intense, traditional cured meat flavor | Umami-rich, slightly sweet, complex fermentation notes |

| Texture | Firm, dry | Tender, sometimes moist due to enzymes |

| Microbial Role | Natural drying inhibits pathogens | Koji mold produces enzymes for breakdown |

| Preservation | Long-term preservation through dehydration and salt | Preservation with enzyme fermentation, shorter shelf-life |

| Common Meats | Ham, prosciutto, bacon | Pork, fish, specialty meats |

| Health Impact | High sodium content | Potential probiotics and enhanced digestibility |

Introduction to Meat Curing Methods

| Dry curing involves applying a mixture of salt, sugar, and spices directly to the meat, drawing out moisture to preserve and develop flavor through dehydration and enzymatic reactions. |

| Koji curing utilizes Aspergillus oryzae mold to ferment the meat surface, enhancing umami and tenderizing the texture by breaking down proteins and fats with natural enzymes. |

| Both methods offer unique preservation techniques, where dry curing emphasizes moisture removal and preservation, while koji curing focuses on biochemical transformation for flavor complexity. |

What is Dry Curing?

Dry curing is a traditional method of preserving meat by applying a mixture of salt and spices directly to the surface. This process draws out moisture, inhibits bacterial growth, and enhances flavor over an extended period.

- Salt Application - Salt is rubbed onto the meat to extract water and preserve the product.

- Moisture Reduction - The drying process reduces water activity, which prevents spoilage.

- Flavor Development - Extended curing time allows complex flavors to develop naturally in the meat.

What is Koji Curing?

What is koji curing in the context of meat preservation? Koji curing utilizes the fermentation properties of the mold Aspergillus oryzae to break down proteins and fats in meat, enhancing flavor and tenderness. This method contrasts with traditional dry curing by accelerating enzymatic reactions and introducing umami-rich compounds naturally.

Key Differences: Dry Curing vs Koji Curing

Dry curing involves the application of salt and spices directly onto the meat surface, promoting moisture loss and flavor development through dehydration over several weeks. Koji curing utilizes the mold Aspergillus oryzae, which produces enzymes that tenderize the meat and enhance umami flavors via biochemical reactions.

Dry curing results in a firmer texture and intensified saltiness, making it ideal for traditional charcuterie such as prosciutto and salami. Koji curing yields a more subtle, complex taste profile with improved tenderness and shorter curing times, often used in innovative culinary practices.

Flavor Profiles: Traditional vs Umami-Rich

Dry curing develops deep, traditional flavors in meats through salt and time, enhancing savory and slightly sweet notes. Koji curing introduces umami-rich complexity by utilizing enzymes from Aspergillus oryzae to break down proteins and fats more rapidly.

Dry cured meats exhibit a classic robust taste profile prized in artisanal charcuterie, characterized by subtle fermentation and drying nuances. Koji curing accelerates flavor development, imparting a pronounced umami taste with hints of nuttiness and mild sweetness. This technique offers a modern twist on traditional curing, appealing to gourmet palates seeking innovative and intense savoriness.

Texture Changes in Dry and Koji Cured Meats

Dry curing induces a firm, dense texture by drawing out moisture through salt and air exposure, creating a chewy, concentrated meat structure. The slow dehydration process enhances protein cross-linking, resulting in a distinctive, resilient bite typical of traditional dry-cured meats like prosciutto and salami.

Koji curing, utilizing Aspergillus oryzae enzymes, softens the meat texture by breaking down muscle proteins and fats, producing a tender, melt-in-the-mouth quality. The enzymatic activity promotes umami development and subtle sweetness, transforming the texture into a delicate, smooth consistency seen in koji-cured specialties.

Health and Safety Considerations

Dry curing involves using salt and sometimes sugar to preserve meats by drawing out moisture, which inhibits bacterial growth and enhances safety when properly controlled. Koji curing utilizes the mold Aspergillus oryzae to break down proteins and fats, creating unique flavors but requiring precise humidity and temperature management to prevent harmful microbial contamination. Both methods demand strict adherence to hygiene practices and environmental monitoring to ensure the cured meats are safe for consumption.

Time and Efficiency: Which Method is Faster?

Dry curing typically requires several weeks to months, making it a slower process compared to koji curing, which can reduce curing time to just a few days. Koji curing accelerates meat preservation by leveraging enzymatic activity, enhancing efficiency without compromising flavor development.

- Dry curing duration - Usually takes 2 to 8 weeks depending on meat thickness and desired flavor intensity.

- Koji curing speed - Can cure meats in 3 to 5 days due to rapid enzymatic breakdown of proteins and fats.

- Efficiency comparison - Koji curing offers a significant time advantage, reducing storage needs and increasing production turnover.

Faster curing with koji enhances workflow efficiency while maintaining quality in meat preservation.

Equipment and Ingredients Needed

Dry curing requires basic equipment such as curing chambers or cool, ventilated spaces along with essential ingredients like salt, sugar, and curing salts (nitrites or nitrates) to preserve meat. Koji curing involves specialized koji spores (Aspergillus oryzae) and controlled humidity and temperature environments to cultivate the mold on the meat surface. While dry curing emphasizes traditional salts and air flow, koji curing integrates enzymatic fermentation with koji to enhance flavor and tenderness.

Related Important Terms

Nuka Dry Cure

Nuka Dry Cure, a traditional Japanese dry curing method using rice bran (nuka), enhances meat flavor and texture by absorbing moisture and promoting beneficial microbial activity, contrasting with koji curing which relies on Aspergillus oryzae fermentation to tenderize and impart umami. Dry curing with nuka preserves meats through natural dehydration and fermentation, resulting in intense, complex flavors without the enzymatic breakdown found in koji curing.

Shio-koji Rub

Shio-koji rub, a blend of fermented rice malt, salt, and water, enhances meat curing by promoting enzymatic breakdown of proteins and natural sugars, resulting in tender texture and deeper umami flavors compared to traditional dry curing. This method accelerates the curing process while maintaining moisture, making it a preferred technique for chefs seeking both flavor complexity and efficient preservation.

Aspergillus-Mediated Fermentation

Aspergillus-mediated fermentation in koji curing utilizes mold enzymes to break down proteins and fats, enhancing flavor complexity and accelerating the curing process compared to traditional dry curing methods that rely on salt and time. This enzymatic activity in koji curing promotes tender texture and umami-rich profiles, setting it apart from the slower, salt-dependent microbial transformations in dry curing.

Umami Enhancement Curing

Dry curing enhances umami in meats by concentrating natural flavors through salt-induced moisture removal, intensifying glutamate content that boosts savory notes. Koji curing introduces enzymes from Aspergillus oryzae, breaking down proteins and starches into amino acids and sugars, significantly amplifying umami richness beyond traditional methods.

Proteolytic Dry Aging

Proteolytic dry aging enhances meat tenderness through enzymatic breakdown of muscle proteins, primarily using natural enzymes during dry curing, which intensifies flavor and texture development without moisture loss. Koji curing employs Aspergillus oryzae to produce proteases that accelerate protein hydrolysis, offering a distinct umami profile and faster maturation compared to traditional dry curing methods.

Enzymatic Tenderization Cure

Dry curing relies on salt to draw moisture out of meat, creating a dense texture through dehydration, whereas koji curing utilizes the enzymatic tenderization properties of Aspergillus oryzae mold to break down proteins and fats, resulting in a more tender and flavorful product. Koji curing enhances meat tenderness by producing proteolytic and lipolytic enzymes that accelerate enzymatic breakdown during the curing process, a method gaining popularity for its natural enzymatic tenderization benefits compared to traditional dry curing.

Nitrate-Free Koji Curing

Dry curing relies on salt and nitrates to preserve meat, enhancing flavor and shelf life but raising concerns over nitrate consumption. Nitrate-free koji curing uses the enzymatic action of Aspergillus oryzae molds to ferment and tenderize meat naturally, reducing sodium content and eliminating synthetic preservatives while promoting umami-rich flavors.

Microbial Surface Inoculation

Dry curing relies on salt and environmental conditions to inhibit microbial growth, promoting surface dehydration that controls spoilage bacteria, while koji curing employs Aspergillus oryzae fermentation to inoculate the meat's surface with beneficial enzymes and microbes, enhancing flavor development and improving microbial safety. Microbial surface inoculation in koji curing actively transforms proteins and fats through enzymatic activity, whereas dry curing primarily limits microbial proliferation via osmotic pressure and reduced water activity.

Hybrid Dry-Koji Cure

The hybrid dry- koji cure method combines traditional dry curing techniques with the enzymatic action of koji mold, enhancing flavor complexity and accelerating protein breakdown for improved texture. This innovative approach yields meats with a balanced umami profile and consistent moisture retention compared to conventional dry curing alone.

Dry curing vs koji curing for curing meats. Infographic

cookingdiff.com

cookingdiff.com