Seasoned cast iron skillets offer a natural non-stick surface that enhances the curing process by evenly distributing heat and preventing food from sticking, which helps achieve a consistent cure. Black oxide skillets provide a durable, corrosion-resistant coating that simplifies maintenance but may not develop the same non-stick qualities as traditional seasoning. Choosing between the two depends on whether you prioritize a naturally non-stick surface or easier upkeep during curing.

Table of Comparison

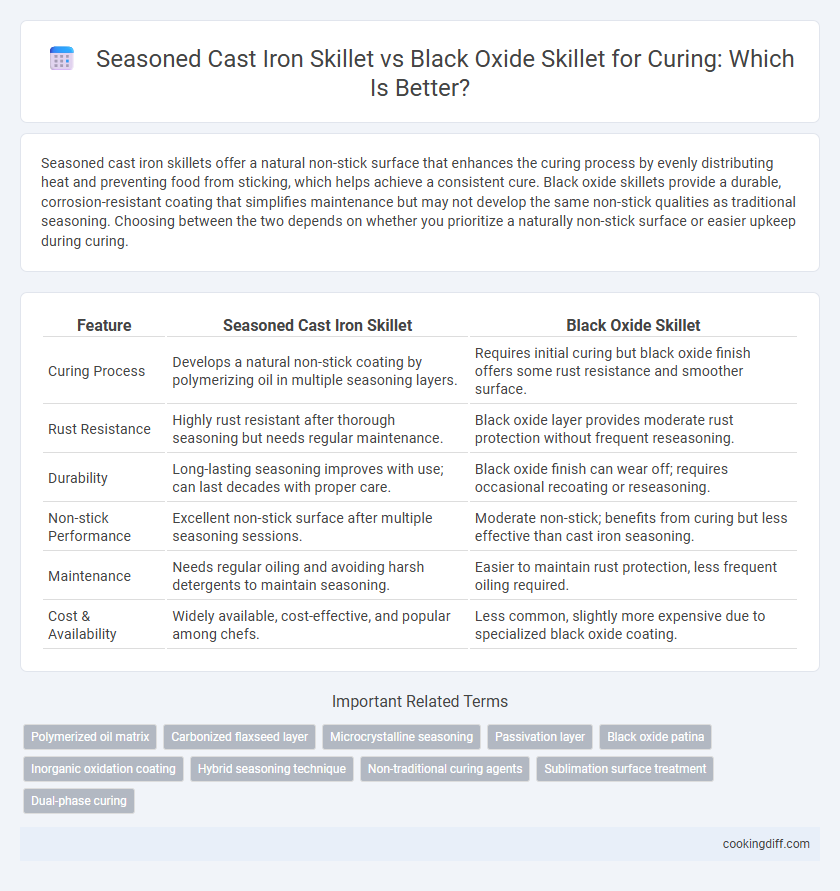

| Feature | Seasoned Cast Iron Skillet | Black Oxide Skillet |

|---|---|---|

| Curing Process | Develops a natural non-stick coating by polymerizing oil in multiple seasoning layers. | Requires initial curing but black oxide finish offers some rust resistance and smoother surface. |

| Rust Resistance | Highly rust resistant after thorough seasoning but needs regular maintenance. | Black oxide layer provides moderate rust protection without frequent reseasoning. |

| Durability | Long-lasting seasoning improves with use; can last decades with proper care. | Black oxide finish can wear off; requires occasional recoating or reseasoning. |

| Non-stick Performance | Excellent non-stick surface after multiple seasoning sessions. | Moderate non-stick; benefits from curing but less effective than cast iron seasoning. |

| Maintenance | Needs regular oiling and avoiding harsh detergents to maintain seasoning. | Easier to maintain rust protection, less frequent oiling required. |

| Cost & Availability | Widely available, cost-effective, and popular among chefs. | Less common, slightly more expensive due to specialized black oxide coating. |

Introduction to Skillet Curing

| Seasoned cast iron skillets develop a natural non-stick surface through repeated oil baking, enhancing durability and flavor retention over time. |

| Black oxide skillets feature a protective layer created by a chemical conversion coating that prevents rust but lacks the seasoning depth found in cast iron. |

| Effective skillet curing involves heating oil to create a polymerized layer; seasoned cast iron skillets rely on this process extensively, while black oxide skillets require minimal seasoning due to their rust-resistant coating. |

What Is a Seasoned Cast Iron Skillet?

A seasoned cast iron skillet has undergone a curing process where multiple layers of oil are baked onto its surface, creating a natural, non-stick coating. This seasoning enhances the skillet's durability and resistance to rust.

- Non-stick surface - The seasoning forms a polymerized layer that prevents food from sticking during cooking.

- Rust prevention - The cured oil layers protect the iron from moisture and oxidation.

- Improved flavor - Regular use and seasoning build a patina that can enhance the taste of dishes cooked over time.

Understanding Black Oxide Skillets

Black oxide skillets feature a chemical conversion coating that enhances rust resistance and provides a smoother, non-reactive surface compared to seasoned cast iron. This black oxide layer reduces the need for extensive seasoning, making the skillet more durable during curing and everyday cooking.

The curing process for black oxide skillets involves applying a thin layer of oil and heating it to create a protective barrier that strengthens the seasoned layer. Proper maintenance ensures the oxide coating remains effective, preventing rust and improving the skillet's longevity and performance.

Curing Process: Seasoned Cast Iron vs Black Oxide

The curing process for a seasoned cast iron skillet involves building up layers of polymerized oil that create a natural, non-stick surface. In contrast, a black oxide skillet undergoes a chemical conversion coating that enhances corrosion resistance without adding seasoning layers.

- Seasoned Cast Iron - Requires repeated oil applications heated to high temperatures for polymerization.

- Black Oxide Skillet - Uses a controlled oxidizing chemical bath to form a durable black coating.

- Durability - Seasoned surfaces improve with use, while black oxide coatings are factory-applied and less affected by everyday cooking.

Both curing methods improve skillet longevity but differ fundamentally in technique and maintenance requirements.

Durability and Longevity Comparison

Seasoned cast iron skillets develop a natural non-stick surface through layers of polymerized oil, enhancing durability with proper care and continuous use. Black oxide skillets feature a protective black oxide coating that resists rust and wear, offering extended longevity even with less maintenance. While both improve with curing, seasoned cast iron's durability relies heavily on regular seasoning, whereas black oxide coatings provide a more consistent rust-resistant layer for long-term use.

Non-Stick Properties: Which Skillet Performs Better?

Seasoned cast iron skillets develop a natural non-stick surface through the polymerization of oils, providing superior release of food compared to black oxide skillets. Black oxide skillets offer moderate non-stick properties but often require additional seasoning to approach the performance of well-seasoned cast iron.

The seasoned cast iron skillet's porous surface absorbs oils, creating a durable, slick layer that improves with use and proper maintenance. In contrast, black oxide skillets have a smoother finish that resists rust but lacks the deep seasoning benefits of cast iron. For curing and cooking tasks demanding optimal non-stick performance, seasoned cast iron is generally the preferred choice.

Maintenance and Care Guidelines

Seasoned cast iron skillets require regular oiling and heat treatment to maintain a non-stick surface and prevent rust, while black oxide skillets benefit from less frequent seasoning due to their corrosion-resistant coating. Proper drying after each use is crucial for both types to avoid moisture-related damage, and storing in a dry environment helps preserve their surfaces. Using mild detergents and avoiding abrasive scrubbing protect the seasoning on cast iron and the oxide layer on black oxide skillets, ensuring longevity and optimal performance.

Health and Food Safety Considerations

Which skillet offers better health and food safety benefits when curing, seasoned cast iron or black oxide? Seasoned cast iron skillets develop a natural non-stick layer through polymerized oils, reducing the risk of harmful chemical leaching during cooking and ensuring safer food preparation. Black oxide skillets, while durable, may lack this protective seasoning and require cautious curing practices to prevent potential metal exposure and food contamination.

Pros and Cons of Each Skillet for Curing

Seasoned cast iron skillets provide a naturally non-stick surface ideal for curing, offering even heat distribution but requiring regular maintenance to prevent rust. Black oxide skillets resist corrosion better and need less upkeep, yet their seasoning layer is less robust for long-term curing use.

- Seasoned cast iron's superior heat retention - Ensures consistent curing temperature essential for optimal results.

- Black oxide's corrosion resistance - Minimizes rust, making it easier to maintain during curing processes.

- Seasoned surface durability - Benefits the curing process by enhancing flavor but demands frequent re-seasoning.

Related Important Terms

Polymerized oil matrix

Seasoned cast iron skillets develop a durable polymerized oil matrix through repeated heating of oil, creating a natural non-stick surface that enhances cooking performance and rust resistance. Black oxide skillets, coated with a chemical black oxide layer, lack this polymerized oil matrix, resulting in a less effective non-stick patina and differing curing requirements.

Carbonized flaxseed layer

A seasoned cast iron skillet develops a durable carbonized flaxseed layer that enhances non-stick properties and resists rust, while a black oxide skillet's surface lacks the porous texture needed for effective curing and carbonization. The flaxseed oil polymerizes on cast iron's rough surface, creating a stable, carbon-rich coating that black oxide finishes cannot replicate, impacting seasoning longevity and cooking performance.

Microcrystalline seasoning

Seasoned cast iron skillets benefit from microcrystalline seasoning that forms a durable, non-stick layer, enhancing rust resistance and improving heat distribution during curing. Black oxide skillets, while offering initial corrosion protection, lack the robust microcrystalline polymer bonds essential for long-term seasoning durability and optimal surface resilience.

Passivation layer

Seasoned cast iron skillets develop a natural passivation layer through polymerized oils that protect against rust and enhance non-stick properties, while black oxide skillets rely on a chemically formed passivation layer providing uniform corrosion resistance and a smoother surface finish. The seasoned layer in cast iron evolves with use and curing, creating a durable, self-repairing barrier compared to the fixed, industrial black oxide coating optimized during manufacturing.

Black oxide patina

Black oxide skillets develop a durable, non-reactive patina that enhances seasoning retention and creates a naturally non-stick surface, making them highly effective for curing compared to traditional seasoned cast iron. The black oxide coating resists rust and reduces the need for repeated oiling, offering superior longevity and performance during the curing process.

Inorganic oxidation coating

Seasoned cast iron skillets develop a natural, polymerized oil layer that provides non-stick properties and corrosion resistance, whereas black oxide skillets feature an inorganic oxidation coating that offers a uniform, durable, and corrosion-resistant surface with enhanced wear protection. The inorganic black oxide coating formed through controlled chemical oxidation delivers superior resistance to rust and reduces the need for frequent maintenance compared to traditional seasoning methods.

Hybrid seasoning technique

Seasoned cast iron skillets develop a durable, non-stick surface through polymerized oils, enhancing heat retention and flavor over time, while black oxide skillets feature a chemically blackened layer offering corrosion resistance but less seasoning depth. The hybrid seasoning technique combines the polymerized seasoning layer of cast iron with the protective black oxide coating, maximizing durability, rust resistance, and non-stick performance during curing and cooking processes.

Non-traditional curing agents

Seasoned cast iron skillets develop a natural non-stick surface through polymerized oils forming a stable seasoning layer, while black oxide skillets rely on a chemical conversion coating that offers corrosion resistance but lacks the organic polymerization essential for traditional seasoning. Non-traditional curing agents, such as flaxseed oil or hemp oil, enhance the polymerized film on cast iron by creating a durable, food-safe patina, a benefit not typically achievable with black oxide surfaces.

Sublimation surface treatment

Seasoned cast iron skillets develop a natural non-stick layer through polymerized oils, enhancing cooking performance and corrosion resistance without altering the metal surface. Black oxide skillets undergo a sublimation surface treatment that chemically converts the iron surface into a durable, rust-resistant layer, providing a uniform black finish but requiring additional seasoning for optimal non-stick properties.

Seasoned cast iron skillet vs Black oxide skillet for curing. Infographic

cookingdiff.com

cookingdiff.com