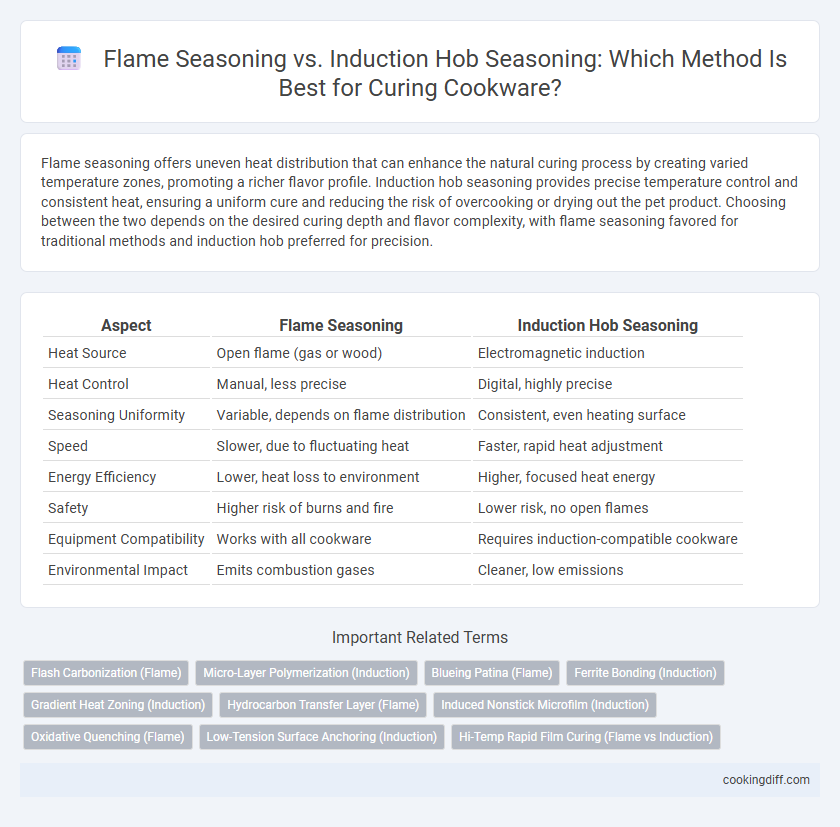

Flame seasoning offers uneven heat distribution that can enhance the natural curing process by creating varied temperature zones, promoting a richer flavor profile. Induction hob seasoning provides precise temperature control and consistent heat, ensuring a uniform cure and reducing the risk of overcooking or drying out the pet product. Choosing between the two depends on the desired curing depth and flavor complexity, with flame seasoning favored for traditional methods and induction hob preferred for precision.

Table of Comparison

| Aspect | Flame Seasoning | Induction Hob Seasoning |

|---|---|---|

| Heat Source | Open flame (gas or wood) | Electromagnetic induction |

| Heat Control | Manual, less precise | Digital, highly precise |

| Seasoning Uniformity | Variable, depends on flame distribution | Consistent, even heating surface |

| Speed | Slower, due to fluctuating heat | Faster, rapid heat adjustment |

| Energy Efficiency | Lower, heat loss to environment | Higher, focused heat energy |

| Safety | Higher risk of burns and fire | Lower risk, no open flames |

| Equipment Compatibility | Works with all cookware | Requires induction-compatible cookware |

| Environmental Impact | Emits combustion gases | Cleaner, low emissions |

Introduction to Seasoning Techniques for Curing

Seasoning is a crucial step in the curing process, influencing flavor development and preservation. Flame seasoning and induction hob seasoning offer distinct heat applications that affect the texture and taste of cured products.

- Flame Seasoning Intensity - Direct flame provides high heat, enhancing smoky flavors and accelerating surface drying during curing.

- Induction Hob Precision - Induction hobs allow controlled, evenly distributed heat, minimizing risk of overcooking and preserving delicate flavors.

- Seasoning Impact on Curing - The choice between flame and induction seasoning alters moisture retention and chemical reactions critical to the quality of cured meats or fish.

What Is Flame Seasoning?

Flame seasoning involves using an open flame to heat cookware, creating a durable, non-stick surface through the polymerization of oils. This traditional method burns off impurities and bonds the seasoning layer directly to the metal.

Unlike induction hob seasoning, which provides controlled and even heating through electromagnetic induction, flame seasoning achieves high temperatures quickly and unevenly. This can result in a more rustic but robust seasoning layer, ideal for cast iron cookware. Flame seasoning also requires greater attention to avoid overheating and damaging the pan's surface during curing.

Understanding Induction Hob Seasoning

Induction hob seasoning provides a precise and consistent heat source essential for effective curing, allowing for better control over temperature compared to traditional flame seasoning. This method minimizes the risk of uneven heating and hotspots that can compromise the curing process and product quality.

Understanding induction hob seasoning involves recognizing its electromagnetic heating mechanism, which directly heats the cookware, resulting in faster response times and energy efficiency. The consistent heat distribution supports optimal seasoning, enhancing the durability and non-stick properties of the cookware during curing.

Heat Distribution: Flame vs Induction

Flame seasoning offers uneven heat distribution, creating hotspots that can lead to inconsistent curing results. This variability can cause parts of the cookware to overheat while others remain underheated, affecting the seasoning layer's durability.

Induction hob seasoning provides precise and uniform heat distribution by directly heating the cookware through magnetic fields. This consistency ensures an even seasoning layer, enhancing the cookware's non-stick properties and longevity during curing.

Efficiency and Speed Comparison

Flame seasoning uses direct heat, providing rapid temperature spikes that speed up the curing process but may lead to uneven seasoning if not carefully managed. Induction hob seasoning offers consistent and precise heat control, enabling more efficient curing with reduced risk of scorching and better retention of flavor. Overall, induction hob seasoning delivers faster and more energy-efficient curing, making it ideal for achieving uniform results in less time.

Surface Results: Color, Texture, and Uniformity

| Surface Result | Flame Seasoning | Induction Hob Seasoning |

|---|---|---|

| Color | Produces uneven, sometimes darker patches due to direct flame exposure causing localized charring. | Delivers consistent, uniform coloration as heat distribution is even across the surface. |

| Texture | Results in varied texture with occasional roughness and blistered spots from fluctuating flame intensity. | Generates smooth and evenly cured surface texture because of precise temperature control. |

| Uniformity | Surface often exhibits irregular seasoning patterns due to the unpredictable nature of flame heat. | Ensures highly uniform seasoning coverage by maintaining constant heat across the material. |

Flavor Impact in Flame vs Induction Seasoning

Flame seasoning imparts a rich, smoky flavor due to direct exposure to open flames, enhancing the taste complexity in curing. Induction hob seasoning offers more controlled heat distribution, resulting in a subtle, consistent flavor without smoky notes.

- Flame seasoning adds depth - The open flame creates charred, smoky undertones that intensify cured food flavors.

- Induction seasoning ensures uniformity - Precise temperature control prevents over-caramelization, preserving natural ingredient flavors.

- Flavor profile varies significantly - Flame seasoning favors bold smokiness, while induction provides cleaner, milder taste nuances.

Equipment Compatibility and Safety

Which equipment offers better compatibility and safety for curing, flame seasoning or induction hob seasoning? Flame seasoning is compatible with most types of cookware, including cast iron and stainless steel, but poses higher risks due to open flames and potential burns. Induction hob seasoning provides safer, more controlled heating with automatic temperature regulation, though it requires cookware with magnetic bases to function effectively.

Cleaning and Maintenance Post-Seasoning

Flame seasoning creates a natural non-stick layer that requires minimal cleaning, while induction hob seasoning often needs more frequent maintenance due to uneven heat distribution. Post-seasoning cleaning for flame-seasoned surfaces is simple, as residues burn off quickly, whereas induction hob surfaces may retain cooking residues requiring gentle scrubbing.

- Flame seasoning minimizes residue build-up - High heat burns off food particles, reducing cleaning effort.

- Induction hob seasoning may cause uneven seasoning - Resulting in spots that trap food debris and need extra care.

- Maintenance frequency varies by seasoning method - Flame seasoning generally demands less frequent maintenance than induction.

Choosing flame seasoning over induction hob seasoning simplifies post-seasoning cleaning and prolongs cookware lifespan.

Related Important Terms

Flash Carbonization (Flame)

Flash carbonization through flame seasoning creates an intense, high-temperature environment that rapidly seals the surface of curing materials, enhancing flavor development and preserving moisture more effectively than induction hob seasoning. Induction hob seasoning provides precise temperature control but lacks the immediate charring effect of flame seasoning, which is crucial for achieving the distinctive smoky aroma and texture in cured products.

Micro-Layer Polymerization (Induction)

Flame seasoning relies on direct heat to carbonize the surface, creating a thin, uneven protective layer, whereas induction hob seasoning utilizes Micro-Layer Polymerization, forming a uniform, durable polymerized coating that enhances corrosion resistance and ensures longer-lasting seasoning performance. This advanced induction method promotes deeper molecular bonding, resulting in superior seasoning quality and improved cookware longevity.

Blueing Patina (Flame)

Flame seasoning creates a distinctive blueing patina on cookware surfaces, enhancing corrosion resistance and longevity by forming a durable oxide layer through intense, uneven heat exposure. Induction hob seasoning offers precise temperature control but lacks the high-temperature variation required to develop the characteristic blueing patina achieved by flame seasoning.

Ferrite Bonding (Induction)

Flame seasoning relies on direct high heat to create a carbonized layer on cookware surfaces, while induction hob seasoning promotes ferrite bonding by generating uniform electromagnetic heat that strengthens the metal's microstructure during curing. This ferrite bonding enhances durability and corrosion resistance, resulting in a more resilient and long-lasting seasoning layer compared to traditional flame methods.

Gradient Heat Zoning (Induction)

Induction hob seasoning offers precise control over gradient heat zoning, enabling uniform curing by targeting specific temperature zones and reducing hotspots common in flame seasoning. This controlled heat distribution enhances the curing process by ensuring consistent texture and flavor development throughout the food.

Hydrocarbon Transfer Layer (Flame)

Flame seasoning creates a Hydrocarbon Transfer Layer by depositing carbonized oils and resins onto cookware surfaces, enhancing non-stick properties and corrosion resistance during curing. Induction hob seasoning lacks this layer, resulting in less effective hydrocarbon bonding and inferior durability in the curing process.

Induced Nonstick Microfilm (Induction)

Induced Nonstick Microfilm seasoning on induction hobs creates a durable, uniform coating that enhances pan longevity and improves heat retention compared to traditional flame seasoning. This microfilm forms at a molecular level, providing superior nonstick properties and reducing the risk of uneven curing commonly associated with open flame methods.

Oxidative Quenching (Flame)

Flame seasoning induces oxidative quenching by exposing cookware to high-temperature combustion gases, which enhances the polymerization of oils into a durable, non-stick layer. In contrast, induction hob seasoning relies on controlled, uniform heating that lacks the oxidative radicals necessary for the same level of oxidative quenching, resulting in a less robust seasoning layer.

Low-Tension Surface Anchoring (Induction)

Low-tension surface anchoring in induction hob seasoning creates a more uniform heat distribution that enhances the curing process by minimizing hotspots and preserving flavor integrity. Flame seasoning, by contrast, often induces uneven thermal stresses that can compromise surface texture and reduce curing efficacy.

Flame seasoning vs induction hob seasoning for curing. Infographic

cookingdiff.com

cookingdiff.com