Seasoned cast iron offers a natural non-stick surface developed over time through polymerized oils, providing excellent heat retention and even heating for curing. Carbon steel, while quicker to season due to its smoother surface and thinner profile, requires more frequent maintenance to maintain its protective layer against rust. Both materials enhance curing efficiency, but cast iron tends to deliver more consistent, long-lasting seasoning, ideal for slow, even heat applications.

Table of Comparison

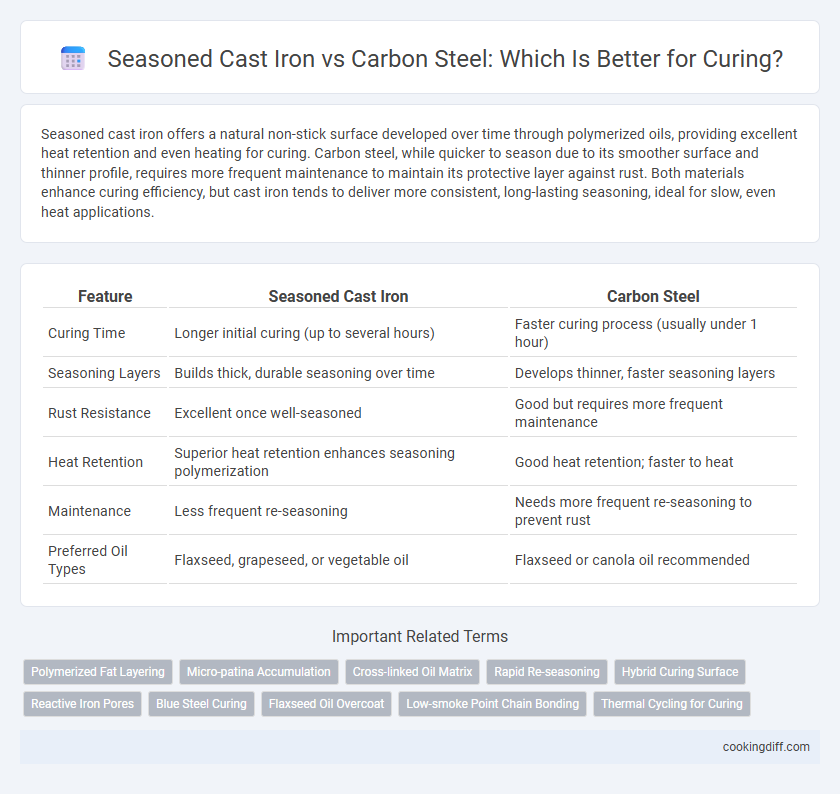

| Feature | Seasoned Cast Iron | Carbon Steel |

|---|---|---|

| Curing Time | Longer initial curing (up to several hours) | Faster curing process (usually under 1 hour) |

| Seasoning Layers | Builds thick, durable seasoning over time | Develops thinner, faster seasoning layers |

| Rust Resistance | Excellent once well-seasoned | Good but requires more frequent maintenance |

| Heat Retention | Superior heat retention enhances seasoning polymerization | Good heat retention; faster to heat |

| Maintenance | Less frequent re-seasoning | Needs more frequent re-seasoning to prevent rust |

| Preferred Oil Types | Flaxseed, grapeseed, or vegetable oil | Flaxseed or canola oil recommended |

Introduction to Curing: Cast Iron vs Carbon Steel

Curing is essential for creating a natural non-stick surface and protecting cookware from rust. Seasoned cast iron develops a durable seasoning layer through polymerized oils, enhancing longevity and heat retention. Carbon steel, lighter and more reactive, forms a thinner seasoning that provides quick responsiveness but requires more frequent maintenance.

Understanding the Curing Process in Cookware

Seasoned cast iron develops a durable, non-stick coating through repeated heating and oil polymerization, creating a protective layer that enhances flavor and prevents rust. Carbon steel undergoes a similar curing process but typically forms a thinner, more reactive seasoning layer that requires more frequent maintenance.

The curing process for both materials involves baking oil onto the surface at high temperatures, chemically bonding it to create a natural, non-stick finish. Cast iron's thicker seasoning offers superior heat retention and even cooking, while carbon steel's lighter seasoning allows for faster heating and greater responsiveness. Proper curing in either cookware type is essential to prevent oxidation, improve performance, and extend the lifespan of the pan.

Material Differences: Cast Iron and Carbon Steel

| Material | Porosity | Heat Retention | Durability | Seasoning Impact |

|---|---|---|---|---|

| Seasoned Cast Iron | Highly porous surface enhances oil absorption during curing | Excellent heat retention and even heating improve seasoning consistency | Extremely durable with proper maintenance against rust | Creates a natural non-stick layer that strengthens with use |

| Carbon Steel | Smoother surface with less porosity requires thorough initial curing | Heats and cools quickly, allowing faster seasoning cycles | Strong and lighter than cast iron but prone to faster oxidation | Develops a thinner seasoning layer that needs regular upkeep |

Heat Retention and Distribution Comparison

Seasoned cast iron offers superior heat retention due to its dense, heavy structure, allowing it to maintain consistent temperatures for extended periods during curing processes. Carbon steel heats up rapidly and provides more responsive heat distribution but loses heat faster compared to cast iron. For curing applications requiring steady, long-lasting heat, seasoned cast iron performs better, while carbon steel suits quicker temperature adjustments.

Nonstick Qualities After Seasoning

Which offers better nonstick qualities after seasoning, seasoned cast iron or carbon steel? Seasoned cast iron develops a thicker, more durable patina that enhances its natural nonstick surface over time. Carbon steel, while quicker to season, often requires more frequent maintenance to maintain its nonstick properties after curing.

Durability and Maintenance for Long-Term Curing

Seasoned cast iron offers exceptional durability for long-term curing, developing a robust non-stick surface that improves with use. Carbon steel requires regular maintenance to prevent rust but is lighter and heats up faster, making it ideal for precise curing control.

- Durability - Cast iron maintains integrity over decades with proper seasoning and use.

- Maintenance - Carbon steel needs frequent oiling and curing to avoid corrosion.

- Heat Retention - Cast iron retains heat longer, providing consistent curing temperatures.

Choosing between seasoned cast iron and carbon steel depends on the balance between durability and ease of maintenance for curing needs.

Ease of Seasoning: Steps for Each Material

Seasoned cast iron requires a longer curing process with multiple layers of oil applied and baked to achieve a durable non-stick surface. Carbon steel cures faster with fewer seasoning steps and is ready for use in less time.

- Cast Iron Cleaning - Thoroughly wash and dry to remove rust or debris before applying oil.

- Oil Application - Coat the surface evenly with a high smoke point oil such as flaxseed or vegetable oil.

- Baking Process - Bake at 450degF (232degC) for one hour and repeat the process 3-4 times for best results.

Cooking Performance: Flavors and Textures

Seasoned cast iron offers superior heat retention, promoting even cooking and enhancing the development of rich, deep flavors in cured foods. Its porous surface improves with use, creating a naturally non-stick coating that intensifies the texture and mouthfeel of dishes.

Carbon steel heats up faster and responds quickly to temperature changes, allowing precise control over cooking, which is ideal for delicate flavor preservation. Its smoother surface produces a slightly lighter crust, contributing to a crispier texture in cured meats and vegetables.

Best Uses for Seasoned Cast Iron vs Carbon Steel

Seasoned cast iron excels in retaining heat evenly, making it ideal for slow-cooking, frying, and searing due to its durable non-stick surface developed through curing. Carbon steel heats up faster and provides superior responsiveness, perfect for high-heat cooking methods like stir-frying or sauteing where quick temperature changes are needed.

Cast iron's robustness and heat retention benefit recipes requiring steady, long-duration heat, preserving flavor and texture in dishes such as stews or baked goods. Carbon steel's lighter weight and faster heating make it preferred for professional kitchens focusing on versatility and rapid cooking adjustments.

Related Important Terms

Polymerized Fat Layering

Seasoned cast iron develops a durable polymerized fat layer that enhances non-stick properties and corrosion resistance through repeated curing cycles, while carbon steel forms a thinner, more reactive polymerized seasoning that requires frequent maintenance to prevent rust. The thicker polymerized layer on cast iron provides superior longevity and protection during high-temperature cooking compared to the more delicate seasoning of carbon steel.

Micro-patina Accumulation

Micro-patina accumulation during curing enhances the non-stick properties of both seasoned cast iron and carbon steel, but cast iron develops a thicker, more durable layer due to its porous surface. Carbon steel, with its smoother texture, forms a thinner micro-patina that requires more frequent maintenance to maintain optimal seasoning.

Cross-linked Oil Matrix

Seasoned cast iron forms a durable, cross-linked oil matrix through polymerization that provides superior non-stick properties and rust resistance, essential for effective curing. Carbon steel also develops this cross-linked layer but typically requires higher temperatures and more frequent re-seasoning to maintain the protective coating.

Rapid Re-seasoning

Seasoned cast iron offers superior rapid re-seasoning due to its porous surface that readily absorbs oils, enhancing non-stick properties and rust resistance quickly. Carbon steel also re-seasons efficiently but requires slightly higher heat and more frequent maintenance to build a durable, protective layer.

Hybrid Curing Surface

Seasoned cast iron offers a naturally non-stick, durable surface developed through polymerized oils, while carbon steel heats rapidly with excellent responsiveness, enabling efficient curing. A hybrid curing surface combines cast iron's retention and seasoning with carbon steel's quick heat adjustment, creating an optimized environment for even seasoning and superior heat management.

Reactive Iron Pores

Seasoned cast iron develops a durable, non-stick surface as its reactive iron pores bond with oils and fats during curing, enhancing flavor retention and rust resistance. Carbon steel's reactive iron pores cure faster but require more frequent seasoning to maintain a protective layer and prevent oxidation.

Blue Steel Curing

Blue steel curing enhances seasoning by developing a durable, corrosion-resistant patina ideal for cast iron and carbon steel cookware. Compared to seasoned cast iron, blue steel's smoother surface promotes even oil polymerization, resulting in a more robust non-stick layer that improves with continued use.

Flaxseed Oil Overcoat

Flaxseed oil overcoat enhances the seasoning on both seasoned cast iron and carbon steel by polymerizing into a durable, non-stick layer that withstands high heat and prevents rust. Its high concentration of omega-3 fatty acids promotes a harder, more resilient surface, making it ideal for curing cookware and maintaining optimal cooking performance.

Low-smoke Point Chain Bonding

Seasoned cast iron develops a durable, low-smoke point chain bonding layer due to its thicker seasoning buildup, enhancing non-stick properties and heat retention during curing. In contrast, carbon steel forms a thinner, less stable seasoning layer that may require more frequent re-curing to maintain optimal performance and prevent smoke buildup.

Seasoned Cast Iron vs Carbon Steel for Curing. Infographic

cookingdiff.com

cookingdiff.com