Brine curing enhances poultry by infusing moisture and salt deep into the meat, resulting in a juicier texture and balanced seasoning. Shio koji curing uses a fermented rice malt rich in enzymes that tenderize the meat while imparting a subtle umami flavor, offering a natural and mildly sweet profile. Comparing both methods, brine curing emphasizes salt penetration and moisture retention, whereas shio koji promoting enzymatic breakdown enhances tenderness and complex taste development.

Table of Comparison

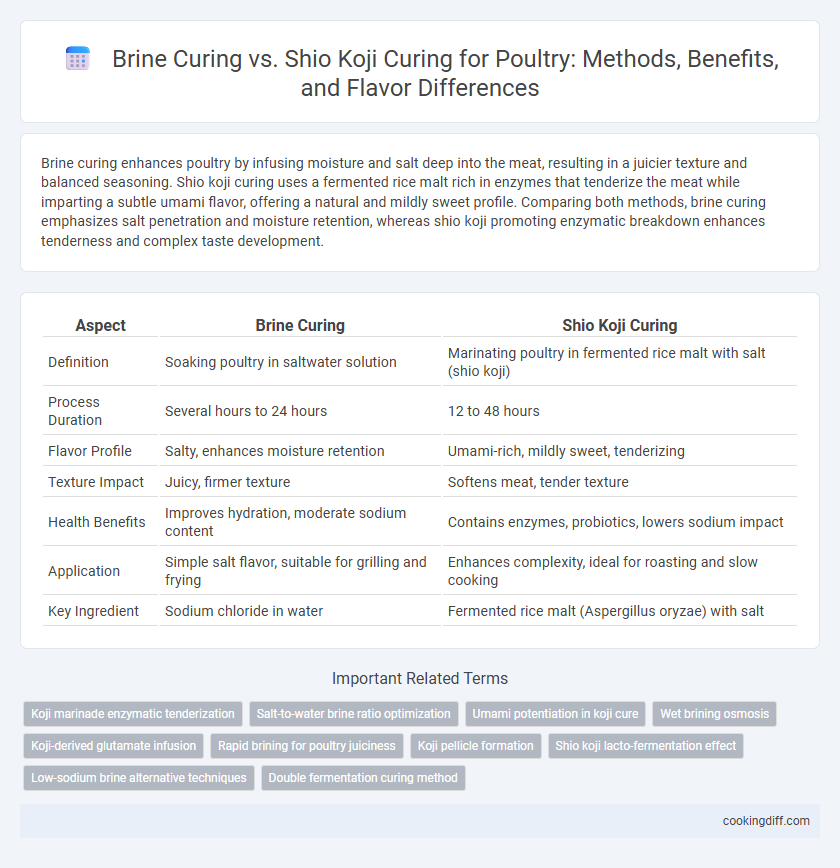

| Aspect | Brine Curing | Shio Koji Curing |

|---|---|---|

| Definition | Soaking poultry in saltwater solution | Marinating poultry in fermented rice malt with salt (shio koji) |

| Process Duration | Several hours to 24 hours | 12 to 48 hours |

| Flavor Profile | Salty, enhances moisture retention | Umami-rich, mildly sweet, tenderizing |

| Texture Impact | Juicy, firmer texture | Softens meat, tender texture |

| Health Benefits | Improves hydration, moderate sodium content | Contains enzymes, probiotics, lowers sodium impact |

| Application | Simple salt flavor, suitable for grilling and frying | Enhances complexity, ideal for roasting and slow cooking |

| Key Ingredient | Sodium chloride in water | Fermented rice malt (Aspergillus oryzae) with salt |

Introduction to Poultry Curing Methods

Brine curing involves soaking poultry in a saltwater solution to enhance moisture retention and flavor development. Shio koji curing uses a fermented rice malt that enzymatically tenderizes the meat while imparting a subtle umami taste. Both methods improve texture and juiciness, with brine offering straightforward salt penetration and shio koji providing natural enzymatic breakdown for deeper flavor complexity.

Understanding Brine Curing: Definition & Process

Brine curing involves soaking poultry in a saltwater solution to enhance moisture retention and flavor. This method contrasts with shio koji curing, which uses a fermented rice culture for enzymatic tenderization and subtle sweetness.

- Brine Solution - A mixture of water, salt, and often sugar or spices, designed to penetrate poultry tissue.

- Osmosis Process - Salt in the brine draws moisture into the meat, increasing juiciness and preserving freshness.

- Time Frame - Poultry is typically immersed for several hours to overnight depending on size and desired flavor intensity.

What is Shio Koji Curing? Basics & Technique

Shio koji curing uses a traditional Japanese marinade made from fermented rice, salt, and koji mold to tenderize and enhance poultry flavor naturally. This method breaks down proteins gently, resulting in juicier and more flavorful meat compared to standard brine curing.

- Enzymatic tenderization - Shio koji contains proteolytic enzymes that break down muscle fibers, improving texture.

- Flavor enhancement - The fermentation process develops umami-rich compounds that deepen poultry taste.

- Health benefits - It uses natural ingredients without artificial additives, promoting a clean label product.

Key Differences: Brine Curing vs Shio Koji Curing

| Key Differences | Brine Curing | Shio Koji Curing |

|---|---|---|

| Primary Ingredients | Salt dissolved in water, often with sugar and spices | Fermented rice malt (koji), salt, and water |

| Flavor Profile | Salty and savory, enhances moisture retention | Umami-rich, subtly sweet, enhances tenderness |

| Enzymatic Activity | Minimal enzyme action, primarily osmotic effect | Active enzymes break down proteins and starches |

| Texture Impact | Improves juiciness by moisture absorption | Softens meat with enzymatic tenderization |

| Curing Time | Typically several hours to overnight | Often requires longer periods, 1-3 days |

Flavor Impact on Poultry: Brine vs Shio Koji

Brine curing enhances poultry by infusing it with a balanced saltiness and moisture, resulting in a juicy texture and traditional savory flavor. This method primarily relies on salt and water to penetrate the meat, intensifying natural poultry flavors while maintaining a clean, straightforward taste.

Shio koji curing uses fermented rice malt enzymes to tenderize poultry and develop a complex umami profile, adding subtle sweetness and depth. The enzymes break down proteins, enriching the meat's flavor beyond saltiness and creating a distinctly savory and aromatic experience compared to brine curing.

Texture Results in Poultry: Comparing Both Methods

Brine curing enhances poultry texture by increasing moisture retention, resulting in juicy and tender meat. Shio koji curing uses enzymes to break down proteins, creating a more tender and subtly sweet flavor profile in the poultry.

- Moisture Retention - Brine curing ensures the meat absorbs saltwater, which improves juiciness and firmness.

- Protein Breakdown - Shio koji's enzymes break down muscle fibers, leading to a softer and more delicate texture.

- Flavor Impact - Shio koji imparts umami and mild sweetness, while brine curing tends to emphasize saltiness and moisture.

Choosing between brine curing and shio koji depends on the desired texture and flavor outcome for poultry dishes.

Time and Convenience Factors

Which method, brine curing or shio koji curing, offers a faster and more convenient process for poultry preparation? Brine curing typically requires only a few hours to overnight, making it a quicker option for those needing faster results. Shio koji curing, while taking longer often up to 24 hours or more, enhances flavor complexity but demands more precise handling and time investment.

Health Considerations and Nutritional Effects

Brine curing poultry enhances moisture retention and can increase sodium content, which may affect cardiovascular health when consumed excessively. Shio koji curing, made from fermented rice malt, not only tenderizes meat naturally but also introduces beneficial enzymes and probiotics that support digestive health.

Shio koji curing tends to preserve more nutrients such as amino acids and vitamins compared to brine curing, which can leach some nutrients into the curing liquid. The enzymatic activity in shio koji improves protein digestibility and may reduce the need for added salt, contributing to a lower sodium intake. Both methods improve flavor, but shio koji offers added health benefits through fermentation-derived bioactive compounds that enhance immune function and gut microbiota balance.

Best Practices for Each Curing Method

Brine curing poultry involves submerging the meat in a saltwater solution, typically composed of water, salt, and optional sugar or spices, for several hours to ensure even moisture retention and enhanced flavor. Maintaining a consistent temperature between 34degF and 40degF (1degC to 4degC) during the brining process prevents bacterial growth while achieving tender, juicy results.

Shio koji curing uses a fermented rice malt mixture rich in enzymes that break down proteins, improving the meat's umami and tenderness without excessive saltiness. Applying shio koji evenly and allowing poultry to cure in refrigeration for 12 to 24 hours optimizes enzymatic activity and flavor development.

Related Important Terms

Koji marinade enzymatic tenderization

Shio koji curing leverages enzymes from koji mold that break down proteins and fats in poultry, resulting in superior tenderization and enhanced umami flavor compared to traditional brine curing. Enzymatic activity in shio koji not only improves texture but also increases moisture retention, producing juicier, more flavorful poultry.

Salt-to-water brine ratio optimization

Optimizing the salt-to-water ratio in brine curing for poultry typically involves a concentration between 5% and 8% salt by weight, balancing flavor enhancement and moisture retention while preventing excess saltiness. Shio koji curing, leveraging koji-derived enzymes and naturally occurring glutamates, allows for reduced salt levels--often below 3%--offering tenderization and umami development without the need for higher salt concentrations found in traditional brines.

Umami potentiation in koji cure

Shio koji curing enhances umami potentiation in poultry by breaking down proteins into amino acids and peptides through its enzymatic activity, resulting in richer, deeper flavors compared to traditional brine curing. Unlike brine curing, which primarily relies on salt penetration for preservation and flavor, shio koji also imparts natural sweetness and complex savory notes, elevating the sensory profile of the meat.

Wet brining osmosis

Brine curing for poultry relies on osmosis to draw salt and moisture into the meat, enhancing juiciness and flavor through a saline solution typically composed of water and salt. Shio koji curing, enriched with enzymes from fermented rice malt, not only promotes osmosis but also tenderizes meat and imparts umami by breaking down proteins during the process.

Koji-derived glutamate infusion

Brine curing enhances poultry texture through salt penetration, while shio koji curing leverages koji-derived glutamate infusion to amplify umami flavor and tenderize meat by breaking down proteins enzymatically. The glutamate compounds from koji fermentation intensify savory taste, offering a natural flavor enhancer beyond traditional salt brining methods.

Rapid brining for poultry juiciness

Rapid brining using brine solutions enhances poultry juiciness by quickly increasing moisture retention through salt diffusion, while shio koji curing improves flavor complexity and tenderness via enzymatic breakdown of proteins. Brine curing is faster and more effective for immediate juiciness, whereas shio koji delivers subtle umami and longer-lasting texture improvements.

Koji pellicle formation

Brine curing relies on salt diffusion to enhance poultry texture and flavor, whereas shio koji curing leverages the enzymatic activity of Aspergillus oryzae, promoting a distinctive koji pellicle formation that tenderizes the meat and improves umami depth. The koji pellicle acts as a biofilm rich in proteases and amylases, accelerating protein breakdown and flavor development beyond the capabilities of traditional salt brining.

Shio koji lacto-fermentation effect

Shio koji curing enhances poultry tenderness and flavor through lacto-fermentation, where enzymes and beneficial microbes break down proteins and fats more effectively than traditional brine curing. This process increases umami compounds and retains moisture, resulting in juicier, more flavorful meat with improved shelf life due to natural preservation by lactic acid bacteria.

Low-sodium brine alternative techniques

Brine curing traditionally uses salt-heavy solutions that enhance moisture retention and flavor but raise sodium content in poultry, while shio koji curing employs a fermented rice malt enzyme that tenderizes meat and develops umami without added salt, serving as an effective low-sodium alternative. Studies indicate shio koji reduces sodium intake by up to 50% compared to conventional brines, making it a healthier option for preserving poultry quality.

Brine curing vs shio koji curing for poultry. Infographic

cookingdiff.com

cookingdiff.com