Larding involves inserting strips of fat directly into meat to enhance moisture retention during cooking, resulting in a juicier texture. Fat washing, on the other hand, infuses flavors into spirits by combining them with fats, which is less about moisture and more about aroma enhancement. For preserving meat juiciness, larding offers a more effective method compared to fat washing, which is primarily a culinary technique for flavor infusion.

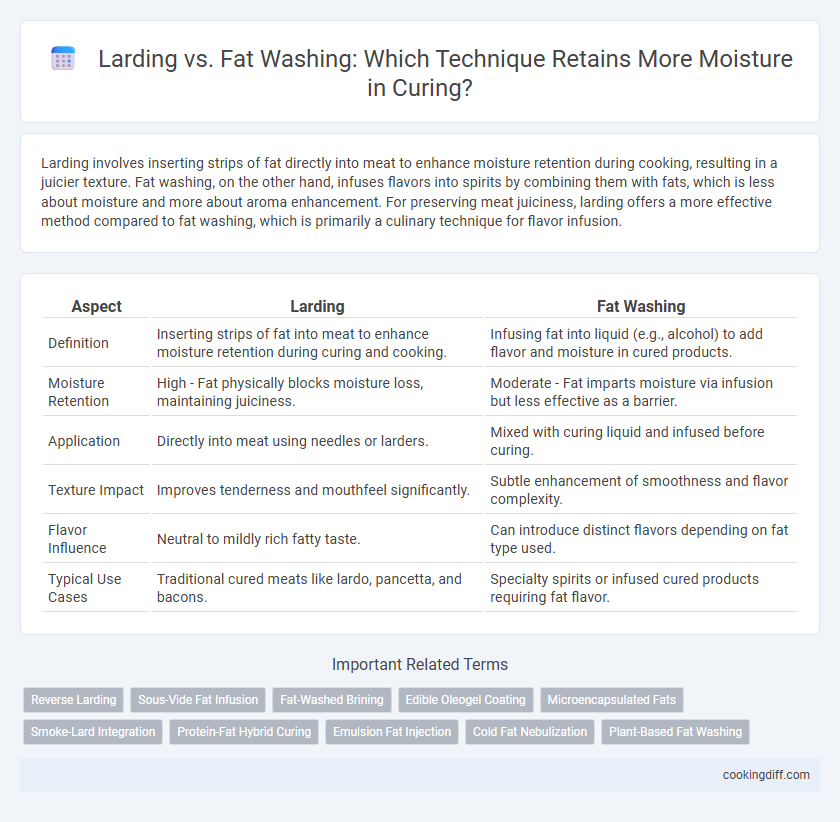

Table of Comparison

| Aspect | Larding | Fat Washing |

|---|---|---|

| Definition | Inserting strips of fat into meat to enhance moisture retention during curing and cooking. | Infusing fat into liquid (e.g., alcohol) to add flavor and moisture in cured products. |

| Moisture Retention | High - Fat physically blocks moisture loss, maintaining juiciness. | Moderate - Fat imparts moisture via infusion but less effective as a barrier. |

| Application | Directly into meat using needles or larders. | Mixed with curing liquid and infused before curing. |

| Texture Impact | Improves tenderness and mouthfeel significantly. | Subtle enhancement of smoothness and flavor complexity. |

| Flavor Influence | Neutral to mildly rich fatty taste. | Can introduce distinct flavors depending on fat type used. |

| Typical Use Cases | Traditional cured meats like lardo, pancetta, and bacons. | Specialty spirits or infused cured products requiring fat flavor. |

Introduction to Larding and Fat Washing

Larding and fat washing are traditional and modern techniques used to enhance moisture retention in cured meats. Both methods incorporate fat to improve texture, flavor, and juiciness during the curing process.

- Larding - Involves inserting strips of fat directly into lean meat to increase moisture and tenderness during curing.

- Fat Washing - Uses fat to infuse flavor and moisture by soaking meat or spirits in fat, then removing the solid fat after infusion.

- Moisture Retention - Both techniques effectively lock in moisture, preventing dryness and enhancing the final product's succulence.

Defining Moisture Retention in Cooking

Moisture retention in cooking refers to the ability of meat to hold onto its natural juices during the cooking process, enhancing tenderness and flavor. Techniques like larding involve inserting strips of fat directly into lean meat to improve moisture content and prevent drying out.

Fat washing, on the other hand, is a method primarily used in beverage preparation to infuse fats without affecting moisture levels in meat. Unlike larding, fat washing does not contribute to moisture retention but adds flavor by emulsifying fat into spirits or cocktails.

What is Larding? Technique and Purpose

What is larding in the context of curing? Larding is a traditional technique that involves inserting strips of fat, such as pork fat, into lean meat to enhance moisture retention during cooking. This method helps maintain juiciness and tenderness by slowly melting the fat throughout the meat.

What is Fat Washing? Process and Application

Fat washing is a culinary technique used to infuse clear spirits with the flavors and aromas of fats, typically from meats or oils, by combining and then chilling the mixture to separate the fat from the liquid. This process allows the liquid to retain subtle fat flavors without the greasy texture, enhancing moisture retention in cooking applications.

The process involves mixing warm fat with alcohol, allowing it to steep for several hours, then freezing the mixture so the solidified fat can be easily removed. Fat washing is applied in curing to impart complex flavors and improve moisture retention in meats and cocktails. This method is favored over larding when a smooth, evenly distributed fat infusion is desired without added texture.

Comparing Larding and Fat Washing for Moisture Retention

Larding involves inserting strips of fat directly into meat, enhancing moisture retention by physically adding fat inside the muscle fibers. Fat washing infuses fat into liquids used for curing, subtly imparting flavor without significantly altering the meat's internal moisture content.

- Larding enhances juiciness - By embedding fat within meat, larding reduces moisture loss during cooking and improves tenderness.

- Fat washing influences flavor profile - It primarily adds fat-derived flavors to curing liquids but does not increase internal fat or moisture in the meat.

- Larding is more effective for moisture retention - Because it physically integrates fat, larding provides better protection against dryness than fat washing.

Best Ingredients for Larding and Fat Washing

Larding and fat washing are two popular curing techniques that enhance moisture retention in meats by introducing fats in different forms. Selecting the best ingredients for each method ensures optimal flavor infusion and juiciness throughout the curing process.

- Pork Back Fat - Rich in unsaturated fats, it is ideal for larding due to its smooth texture and mild flavor.

- Beef Tallow - Commonly used in fat washing, beef tallow imparts a deep, savory taste while locking in moisture.

- Duck Fat - Its high smoke point and aromatic qualities make duck fat perfect for fat washing, enhancing both moisture and flavor complexity.

Using high-quality, fresh fats specific to the curing technique maximizes moisture retention and flavor development.

Flavor Enhancement: Larding Versus Fat Washing

Larding infuses moisture directly into meats by inserting strips of fat, enhancing juiciness and delivering rich, savory flavors internally. Fat washing involves infusing spirits or oils with fat to impart subtle, layered taste profiles without adding moisture to the food itself. Both techniques elevate flavor complexity, but larding improves texture and moisture retention, while fat washing emphasizes aromatic depth in cocktails or dishes.

Step-by-Step Guide: Larding for Juicier Meats

Larding involves inserting strips of fat directly into lean cuts of meat to enhance moisture retention during cooking. This technique ensures even distribution of fat, resulting in juicier and more flavorful meat compared to fat washing, which infuses fat externally.

Start by selecting high-quality pork fat or bacon fat strips for larding, then use a larding needle to thread the fat uniformly through the meat. Cook the larded meat slowly to allow the internal fat to melt, basting the meat internally for maximum juiciness and tender texture.

Step-by-Step Guide: Fat Washing for Moisture Lock

| Step 1: Choose Fat | Select high-quality fat such as pork lard or beef tallow to ensure optimal flavor and moisture retention during curing. |

| Step 2: Melt Fat | Slowly render the fat at low heat to preserve its integrity and enhance absorption into the meat fibers for effective moisture lock. |

| Step 3: Combine Ingredients | Mix the melted fat with curing agents like salt, sugar, and spices, distributing evenly for uniform moisture retention throughout the meat. |

| Step 4: Apply Fat Washing | Envelop the meat in the fat mixture, ensuring complete coverage to create a barrier that seals in juices during the curing and aging process. |

| Step 5: Cure Duration | Allow the meat to cure under controlled temperature and humidity for a specific time frame, typically 24 to 72 hours, optimizing moisture retention. |

| Step 6: Refrigerate and Press | Refrigerate meat under weight to help the fat penetrate deeply, further enhancing moisture lock and texture before final cooking or storage. |

Related Important Terms

Reverse Larding

Reverse larding enhances moisture retention by injecting fat directly into lean cuts, creating an even distribution that improves juiciness compared to traditional larding or fat washing methods. Unlike fat washing, which infuses flavor but less moisture, reverse larding maintains structural integrity and ensures prolonged succulence during curing and cooking processes.

Sous-Vide Fat Infusion

Larding and fat washing both enhance moisture retention in sous-vide cooking, but sous-vide fat infusion allows precise fat distribution at the molecular level, resulting in deeper flavor penetration and juicier textures. This method leverages controlled temperature to dissolve and integrate fats directly into muscle fibers, outperforming traditional larding's physical insertion of fat strips.

Fat-Washed Brining

Fat-washed brining enhances moisture retention by infusing oils or animal fats into the brine, creating a hydrophobic barrier that reduces water loss during cooking. Unlike traditional larding, which physically inserts fat into meat, fat-washed brining integrates fat molecules at a molecular level, improving texture and juiciness without altering the meat's structure.

Edible Oleogel Coating

Larding enhances moisture retention by inserting solid fat directly into meat fibers, creating internal barriers against drying, while fat washing saturates the surface with flavored fats but may lack deep moisture protection. Edible oleogel coatings combine the benefits of both methods by forming a semi-solid, lipid-based barrier that traps moisture effectively and delivers enhanced flavor stability during curing.

Microencapsulated Fats

Microencapsulated fats in fat washing provide superior moisture retention compared to traditional larding by delivering controlled release of lipids within cured meats, enhancing juiciness and texture. This encapsulation technology improves fat distribution uniformity, reducing drying loss and oxidation while preserving flavor stability throughout the curing process.

Smoke-Lard Integration

Larding enhances moisture retention by inserting solid fat directly into meat fibers, creating pockets that slowly render during cooking, while fat washing infuses smoky flavors into liquid fats used for curing without altering the meat's texture. Smoke-lard integration combines the benefits of both methods by using smoked lard in the larding process, intensifying smoky flavors and maximizing juiciness through fat's even distribution within the muscle.

Protein-Fat Hybrid Curing

Larding enhances moisture retention through direct fat infusion into meat fibers, creating a protein-fat hybrid curing effect that improves texture and juiciness. Fat washing, by contrast, infuses fat-soluble flavors into proteins but offers less impact on moisture preservation compared to the structural integration achieved by larding.

Emulsion Fat Injection

Emulsion fat injection offers superior moisture retention compared to traditional larding and fat washing by uniformly dispersing fat throughout the meat fibers, enhancing juiciness and texture during curing. Unlike larding, which inserts solid fat pieces, and fat washing that coats surface fats, emulsion fat injection ensures consistent moisture distribution and improved curing efficiency.

Cold Fat Nebulization

Cold Fat Nebulization enhances moisture retention by evenly distributing fine fat particles throughout the meat, creating a uniform barrier that preserves juiciness more effectively than traditional larding. Unlike fat washing, which relies on surface application and absorption over time, Cold Fat Nebulization penetrates deeper, improving texture and flavor without over-saturating the product.

Larding vs Fat Washing for moisture retention Infographic

cookingdiff.com

cookingdiff.com