Salt box curing for pancetta creates a traditional, dry environment that enhances flavor through slow, natural moisture reduction, resulting in a firmer texture and pronounced saltiness. Vacuum bag curing, on the other hand, maintains a controlled, moist atmosphere that accelerates salt penetration and retains juiciness while minimizing bacterial contamination. Choosing between the two methods depends on desired taste intensity and texture, with salt box offering a classic, robust profile and vacuum bag ensuring consistent, tender results.

Table of Comparison

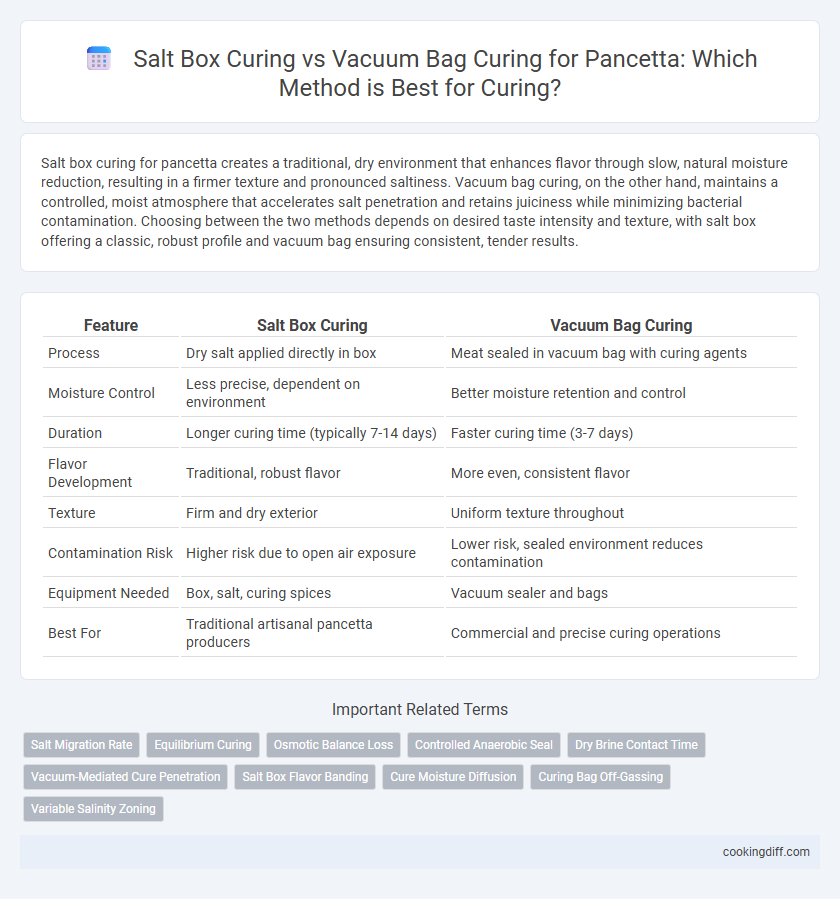

| Feature | Salt Box Curing | Vacuum Bag Curing |

|---|---|---|

| Process | Dry salt applied directly in box | Meat sealed in vacuum bag with curing agents |

| Moisture Control | Less precise, dependent on environment | Better moisture retention and control |

| Duration | Longer curing time (typically 7-14 days) | Faster curing time (3-7 days) |

| Flavor Development | Traditional, robust flavor | More even, consistent flavor |

| Texture | Firm and dry exterior | Uniform texture throughout |

| Contamination Risk | Higher risk due to open air exposure | Lower risk, sealed environment reduces contamination |

| Equipment Needed | Box, salt, curing spices | Vacuum sealer and bags |

| Best For | Traditional artisanal pancetta producers | Commercial and precise curing operations |

Introduction to Pancetta Curing Methods

Pancetta curing methods influence flavor, texture, and preservation quality, with salt box curing and vacuum bag curing being popular techniques. Salt box curing uses dry salt and air exposure, while vacuum bag curing relies on sealing meat to retain moisture and intensify flavor.

- Salt box curing - involves layering pancetta with salt and spices in a box, allowing gradual moisture loss and natural fermentation.

- Vacuum bag curing - seals pancetta in airtight bags, accelerating cure penetration and reducing microbial contamination risks.

- Flavor and texture impact - salt box curing results in a firmer texture and complex flavor, whereas vacuum bag curing offers a softer, more uniformly cured product.

What is Salt Box Curing?

Salt box curing is an ancient preservation technique where pancetta is layered with salt and stored in a wooden box to draw out moisture naturally. This method contrasts with vacuum bag curing, which uses airtight sealing to control moisture and flavor development more precisely.

- Traditional method - Salt box curing relies on salt's natural desiccant properties to cure pancetta without modern equipment.

- Flavor impact - It produces a more rustic, intensely salty flavor due to prolonged salt exposure and slow moisture loss.

- Environmental factors - Ambient temperature and humidity significantly influence the curing process in a salt box setup.

Understanding Vacuum Bag Curing

Vacuum bag curing for pancetta enhances flavor infusion by tightly sealing the meat, preventing oxidation and moisture loss while promoting even salt distribution. This method accelerates the curing process compared to traditional salt box curing by maintaining a controlled environment that inhibits bacterial growth. Vacuum bag curing ensures consistent texture and color, resulting in a tender, richly flavored pancetta ideal for culinary applications.

Key Differences: Salt Box vs Vacuum Bag

Salt box curing for pancetta involves a dry environment where salt and spices draw moisture out, promoting a firmer texture and traditional flavor profile. Vacuum bag curing uses an airtight seal to enhance salt absorption while retaining moisture, resulting in a more tender and evenly cured product. Key differences include moisture retention, texture outcome, and curing speed, with vacuum bag curing typically accelerating the process compared to salt box methods.

Flavor Profiles: Impact of Each Method

Salt box curing enhances pancetta's flavor by promoting a slow, natural fermentation that develops deep, complex umami notes and a slightly tangy finish. This traditional method allows salt and spices to penetrate gradually, resulting in a robust and well-rounded taste profile.

Vacuum bag curing, on the other hand, accelerates the curing process by tightly sealing pancetta, which preserves moisture and intensifies the meat's inherent sweetness and tenderness. The reduced exposure to air limits oxidation, producing a cleaner and milder flavor compared to salt box curing.

Texture Outcomes in Pancetta Curing

Salt box curing produces a firmer, drier texture in pancetta due to the extended exposure to salt and air, enhancing moisture loss and flavor concentration. Vacuum bag curing results in a softer, more uniform texture by limiting air exposure and retaining moisture throughout the curing process.

- Salt box curing creates a denser texture - prolonged salt contact and air drying firm up the pancetta's structure.

- Vacuum bag curing maintains moisture - sealing the meat preserves juiciness resulting in a tender bite.

- Texture contrast affects culinary applications - firmer pancetta suits slicing for charcuterie while softer pancetta enhances cooking versatility.

Choosing the curing method depends on the desired pancetta texture and final use in recipes.

Safety and Consistency Considerations

Which method ensures greater safety and consistency in pancetta curing, salt box or vacuum bag curing? Salt box curing relies on dry salt to inhibit bacterial growth, but can have uneven salt distribution leading to inconsistent results. Vacuum bag curing provides a controlled, anaerobic environment that enhances safety by reducing contamination risks and promotes uniform curing throughout the pancetta.

Time Requirements for Each Method

Salt box curing of pancetta typically requires a longer curing time, often ranging from 10 to 14 days, as the salt slowly penetrates the meat to draw out moisture and enhance flavor. This method is favored for its traditional approach but demands patience and careful monitoring to avoid over-curing.

Vacuum bag curing significantly reduces the curing duration, usually completing the process within 5 to 7 days due to the airtight environment accelerating salt absorption and moisture extraction. This technique ensures a more controlled and uniform cure, minimizing the risk of spoilage. Its efficiency makes vacuum bag curing ideal for faster production cycles without compromising pancetta quality.

Equipment and Ingredient Needs

| Method | Equipment Needed | Ingredient Requirements |

|---|---|---|

| Salt Box Curing | Wooden or plastic salt box, weight for pressuring, breathable cloth cover | Coarse salt, sugar, spices, and nitrates for preservation and flavor infusion |

| Vacuum Bag Curing | Vacuum sealer machine, vacuum bags, refrigeration unit | Salt, sugar, nitrates, and optional herbs or spices for controlled flavor and moisture retention |

Related Important Terms

Salt Migration Rate

Salt box curing for pancetta allows a slower salt migration rate, resulting in a more gradual flavor penetration and moisture retention, which enhances texture. Vacuum bag curing accelerates salt migration due to the close contact and reduced oxygen exposure, shortening curing time but potentially affecting the evenness of salt distribution.

Equilibrium Curing

Salt box curing achieves equilibrium curing more slowly due to uneven salt penetration and moisture loss control, which can result in inconsistent texture and flavor in pancetta. Vacuum bag curing enhances equilibrium curing efficiency by creating a controlled environment that promotes uniform salt diffusion and reduces oxidation, yielding a more consistent and flavorful pancetta.

Osmotic Balance Loss

Salt box curing for pancetta induces a more pronounced osmotic balance loss by drawing moisture out through a high concentration of salt, which accelerates dehydration and firming of the meat. Vacuum bag curing, in contrast, maintains a more controlled osmotic environment by limiting air exposure, resulting in slower moisture loss and a tenderer texture.

Controlled Anaerobic Seal

Vacuum bag curing for pancetta ensures a controlled anaerobic seal that minimizes oxygen exposure, enhancing flavor development and preventing spoilage compared to traditional salt box curing. This method promotes uniform salt penetration and consistent moisture retention, resulting in superior texture and safety.

Dry Brine Contact Time

Salt box curing for pancetta involves a longer dry brine contact time, typically 7 to 10 days, which enhances salt penetration and flavor development. Vacuum bag curing shortens the dry brine contact time to 3 to 5 days by creating a tight seal that accelerates moisture extraction and uniform curing.

Vacuum-Mediated Cure Penetration

Vacuum bag curing for pancetta enhances vacuum-mediated cure penetration by creating a low-pressure environment that facilitates deeper and more uniform salt and seasoning absorption, resulting in improved texture and flavor development. This method outperforms traditional salt box curing by reducing curing time and minimizing surface drying, ensuring consistent quality throughout the meat.

Salt Box Flavor Banding

Salt box curing for pancetta enhances flavor banding by allowing gradual salt absorption and moisture migration, creating distinct, well-defined flavor layers throughout the meat. Vacuum bag curing leads to more uniform salt distribution but lacks the pronounced flavor gradients achieved with salt box curing, resulting in a less complex taste profile.

Cure Moisture Diffusion

Salt box curing for pancetta relies on direct salt contact, promoting slower moisture diffusion and allowing gradual flavor penetration, while vacuum bag curing accelerates moisture exchange by creating a sealed environment that enhances salt absorption and uniform cure distribution. Vacuum bag curing optimizes clarity in moisture gradients, resulting in more consistent texture and reduced surface dryness compared to traditional salt box methods.

Curing Bag Off-Gassing

Salt box curing for pancetta allows natural off-gassing through the open, porous environment, promoting gradual moisture evaporation and flavor development. Vacuum bag curing traps gases inside the sealed bag, which can hinder off-gassing but maintains consistent humidity and reduces contamination risks.

Salt box curing vs Vacuum bag curing for pancetta. Infographic

cookingdiff.com

cookingdiff.com