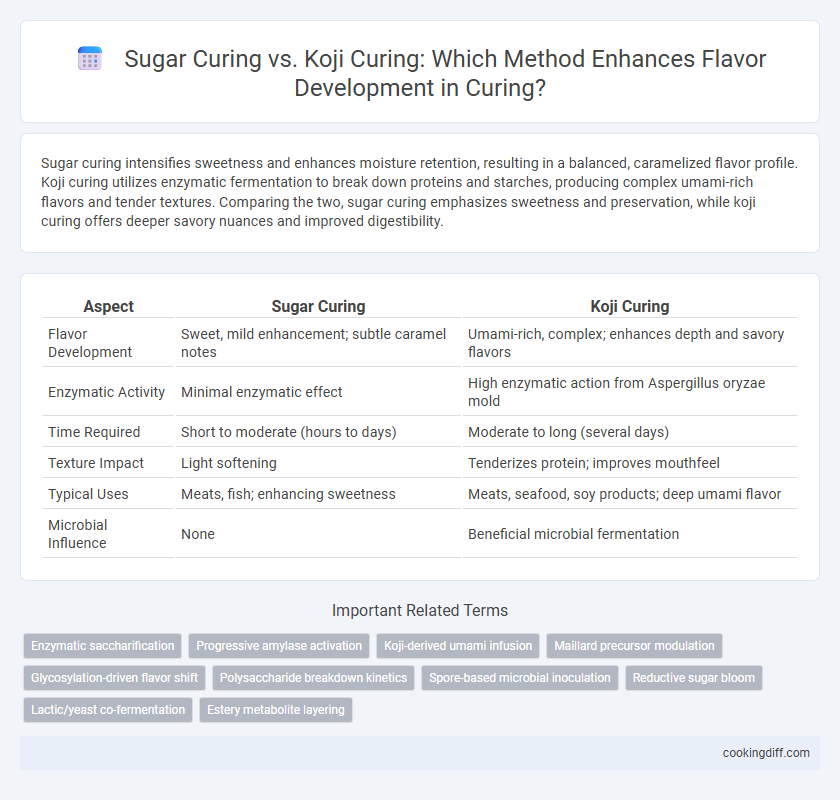

Sugar curing intensifies sweetness and enhances moisture retention, resulting in a balanced, caramelized flavor profile. Koji curing utilizes enzymatic fermentation to break down proteins and starches, producing complex umami-rich flavors and tender textures. Comparing the two, sugar curing emphasizes sweetness and preservation, while koji curing offers deeper savory nuances and improved digestibility.

Table of Comparison

| Aspect | Sugar Curing | Koji Curing |

|---|---|---|

| Flavor Development | Sweet, mild enhancement; subtle caramel notes | Umami-rich, complex; enhances depth and savory flavors |

| Enzymatic Activity | Minimal enzymatic effect | High enzymatic action from Aspergillus oryzae mold |

| Time Required | Short to moderate (hours to days) | Moderate to long (several days) |

| Texture Impact | Light softening | Tenderizes protein; improves mouthfeel |

| Typical Uses | Meats, fish; enhancing sweetness | Meats, seafood, soy products; deep umami flavor |

| Microbial Influence | None | Beneficial microbial fermentation |

Introduction to Sugar Curing and Koji Curing

| Sugar curing involves applying a mixture of sugar, salt, and spices to preserve and enhance the flavor of meats by drawing out moisture and promoting enzymatic activity. |

| Koji curing uses Aspergillus oryzae, a fermentation mold, to break down proteins and starches, intensifying umami flavors and tenderizing the meat through enzymatic processes. |

| Both methods achieve distinct flavor profiles, with sugar curing emphasizing sweetness and salt balance, while koji curing develops complex savory notes through natural fermentation. |

Historical Background of Sugar Curing

Sugar curing dates back to ancient China, where it was used to preserve meats by drawing out moisture and enhancing flavor through crystallized sugar. This method spread through Europe during the Middle Ages, particularly in the Mediterranean, becoming a staple in charcuterie for its ability to develop sweet and savory profiles. Historical records highlight sugar curing's role in creating cured products like hams and sausages before the modern rise of koji curing techniques.

Origins and Rise of Koji Curing Techniques

Sugar curing, a traditional preservation method dating back centuries, relies on sugar's hygroscopic properties to inhibit microbial growth and enhance sweetness. Koji curing originates from East Asia, utilizing Aspergillus oryzae mold to break down proteins and starches, creating complex umami flavors and tender textures.

- Sugar curing origins - Primarily developed in European and American culinary traditions to sweeten and preserve meats and fish.

- Koji curing rise - Gained global attention through Japanese cuisine, with modern chefs adopting it for innovative flavor profiles.

- Flavor impact - Sugar curing emphasizes sweetness and firmness while koji curing imparts savory depth and improved digestibility.

The rising popularity of koji curing reflects a broader shift toward fermentation-based techniques that unlock sophisticated taste and texture in foods.

Chemical Processes in Sugar Curing

Sugar curing utilizes osmotic pressure to draw moisture out of the meat while promoting Maillard reactions that develop complex, sweet-savory flavors. In contrast, koji curing relies on enzymatic activity from Aspergillus oryzae to break down proteins and starches, resulting in umami-rich profiles.

- Osmosis-driven dehydration - Sugar molecules create a hypertonic environment, extracting water from meat cells to inhibit microbial growth and concentrate flavors.

- Maillard reaction enhancement - Reducing sugars in sugar curing react with amino acids during curing and cooking, forming browned flavor compounds and pigments.

- Comparative enzymatic impact - Unlike sugar curing's chemical pathways, koji's enzymatic proteases and amylases facilitate deeper flavor complexity through biochemical breakdown.

Enzymatic Reactions in Koji Curing

Koji curing utilizes Aspergillus oryzae to stimulate enzymatic reactions that break down proteins and starches into amino acids and sugars, enhancing umami flavor and sweetness. These enzymatic processes produce complex flavor compounds that are distinct from those generated in traditional sugar curing.

Compared to sugar curing, which primarily relies on osmotic pressure to draw out moisture and add a sweet surface glaze, koji curing deeply transforms the texture and taste through prolonged enzymatic activity. The proteases and amylases in koji accelerate maturation, resulting in a richer, more savory profile unique to fermented foods.

Flavor Profile Comparison: Sugar vs. Koji Cured Foods

Sugar curing enhances flavor by drawing out moisture and promoting slight caramelization, resulting in a sweeter, mellow taste with subtle savory undertones. This method emphasizes a delicate balance between sweetness and saltiness, ideal for meats and fish where a gentle, rounded flavor is desired.

Koji curing employs the enzymatic action of Aspergillus oryzae mold to break down proteins and starches into amino acids and sugars, generating complex umami-rich flavors and a deeper savory profile. Foods cured with Koji develop a pronounced depth and richness, often described as nutty, tangy, and distinctly fermented compared to sugar-cured counterparts.

Impact on Texture: Sugar Curing vs. Koji Curing

How do sugar curing and koji curing impact the texture of cured foods differently? Sugar curing tends to create a firmer, denser texture by drawing out moisture through osmotic pressure, resulting in a slightly sticky surface. Koji curing breaks down proteins and starches enzymatically, producing a tender, more delicate texture with enhanced umami complexity.

Popular Dishes and Applications for Each Method

Sugar curing enhances sweetness and preserves texture, commonly used in dishes like cured salmon and bacon. Koji curing leverages enzymatic fermentation to develop umami and depth, ideal for aged meats and fermented soy products.

- Sugar curing in smoked bacon - Imparts a balanced sweetness that complements smoky flavors while preserving juiciness.

- Koji curing in dry-aged beef - Breaks down proteins to create tender, richly flavored meat with enhanced umami notes.

- Sugar curing of salmon gravlax - Draws out moisture and infuses subtle sweetness, perfect for cold appetizers.

Health and Safety Considerations in Curing

Sugar curing inhibits harmful bacteria growth by creating an osmotic environment that preserves food safely, making it a simple and widely trusted method in home and commercial curing. Koji curing employs Aspergillus oryzae mold to break down proteins and sugars, enhancing flavor while requiring precise temperature and humidity control to prevent undesirable microbial contamination.

Health and safety considerations for sugar curing include monitoring salt and sugar levels to avoid excessive sodium or sugar intake, which can impact cardiovascular health. Koji curing demands strict hygiene and regulated fermentation conditions to avoid the proliferation of pathogens or mycotoxins. Both methods require proper handling and storage to ensure safe consumption and maximize flavor development.

Related Important Terms

Enzymatic saccharification

Sugar curing relies on osmosis to draw moisture and intensify sweetness, but Koji curing utilizes Aspergillus oryzae enzymes to actively perform enzymatic saccharification, breaking down starches into simpler sugars that enhance umami and complex flavor profiles. The enzymatic action in Koji curing not only generates natural sugars but also promotes protein breakdown, resulting in a richer and more nuanced taste compared to conventional sugar curing.

Progressive amylase activation

Sugar curing enhances flavor development primarily through the gradual activation of amylase enzymes that break down starches into simple sugars, intensifying sweetness and depth. Koji curing accelerates this process by introducing Aspergillus oryzae, which produces potent amylases that progressively convert starches, resulting in more complex umami and aromatic profiles.

Koji-derived umami infusion

Koji curing enhances flavor development by infusing rich umami through enzymatic breakdown of proteins into amino acids, notably glutamate, which intensifies savory depth beyond the simple sweetness from sugar curing. The koji-derived umami compounds create more complex taste profiles, improving mouthfeel and enhancing overall sensory experience in cured products.

Maillard precursor modulation

Sugar curing enhances Maillard reaction precursors by increasing reducing sugars, which intensifies complex flavor profiles and browning in cured meats. Koji curing utilizes Aspergillus oryzae enzymes to break down proteins and starches into amino acids and sugars, finely modulating Maillard precursors for balanced umami and caramelized notes.

Glycosylation-driven flavor shift

Sugar curing and koji curing both enhance flavor development through glycosylation-driven flavor shifts, but koji curing leverages enzymatic activity from Aspergillus oryzae to produce complex glycosides, resulting in deeper umami and caramelized notes. Sugar curing primarily induces surface-level glycosylation, creating sweeter and milder flavor profiles compared to the more intricate and savory compounds generated during koji fermentation.

Polysaccharide breakdown kinetics

Sugar curing relies on osmotic dehydration and slow enzymatic breakdown of polysaccharides by endogenous enzymes, resulting in gradual flavor enhancement. Koji curing utilizes Aspergillus oryzae enzymes to accelerate polysaccharide hydrolysis, rapidly releasing sugars and amino acids that intensify umami and complex flavor profiles.

Spore-based microbial inoculation

Sugar curing relies on high concentrations of sugar to draw moisture out of food, promoting flavor concentration through osmotic dehydration, while Koji curing uses spore-based microbial inoculation with Aspergillus oryzae to enzymatically break down proteins and starches, enhancing umami and complex flavor profiles. The spore-based inoculation in Koji curing enables dynamic enzymatic activity that produces amino acids and sugars, significantly intensifying savory notes compared to the sugar curing method.

Reductive sugar bloom

Sugar curing enhances flavor development through the formation of reductive sugar bloom, promoting Maillard reactions that create complex savory notes and a slightly sweet crust. Koji curing utilizes Aspergillus oryzae enzymes to break down proteins and carbohydrates, producing umami-rich amino acids and fermentative flavors while minimizing sugar bloom effects for a cleaner taste profile.

Lactic/yeast co-fermentation

Sugar curing relies primarily on osmotic pressure to preserve and enhance food flavor, promoting the growth of lactic acid bacteria that contribute mild sourness and subtle sweetness. Koji curing utilizes Aspergillus oryzae to ferment sugars into enzymes, driving complex lactic and yeast co-fermentation that produces rich umami, amino acids, and intricate flavor profiles unmatched by traditional sugar curing.

Sugar curing vs Koji curing for flavor development. Infographic

cookingdiff.com

cookingdiff.com