Traditional skillets offer consistent heat distribution essential for curing pets' food thoroughly, ensuring even texture and flavor development. Blue steel pans heat up quickly and retain heat well, providing a better sear and enhanced crust formation without burning. Choosing a blue steel pan can improve curing efficiency by combining rapid heating with durable, non-reactive surfaces ideal for maintaining food quality.

Table of Comparison

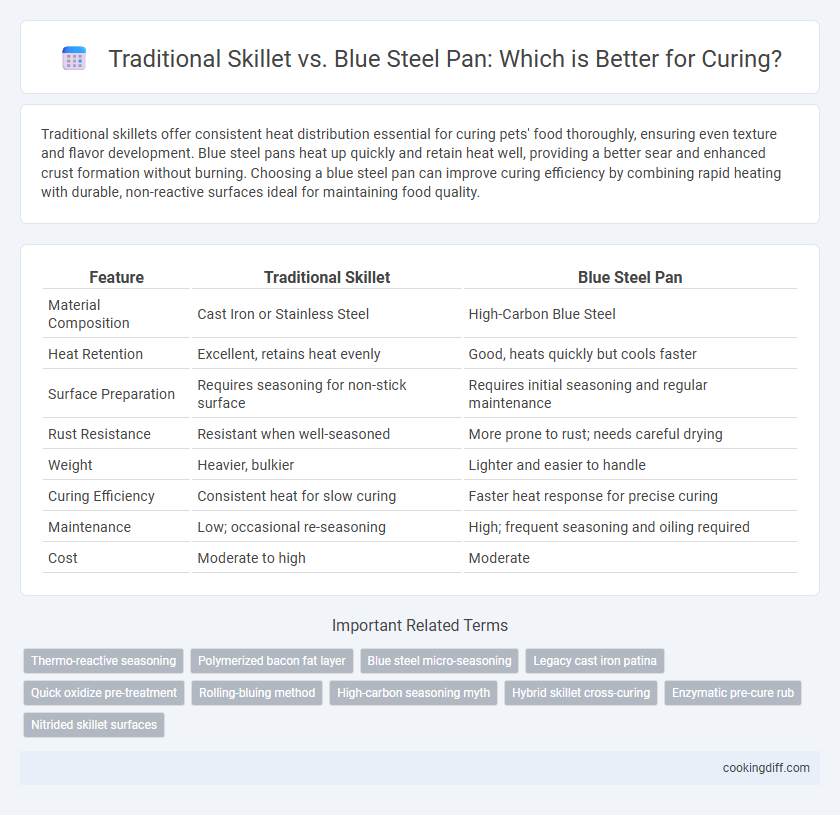

| Feature | Traditional Skillet | Blue Steel Pan |

|---|---|---|

| Material Composition | Cast Iron or Stainless Steel | High-Carbon Blue Steel |

| Heat Retention | Excellent, retains heat evenly | Good, heats quickly but cools faster |

| Surface Preparation | Requires seasoning for non-stick surface | Requires initial seasoning and regular maintenance |

| Rust Resistance | Resistant when well-seasoned | More prone to rust; needs careful drying |

| Weight | Heavier, bulkier | Lighter and easier to handle |

| Curing Efficiency | Consistent heat for slow curing | Faster heat response for precise curing |

| Maintenance | Low; occasional re-seasoning | High; frequent seasoning and oiling required |

| Cost | Moderate to high | Moderate |

Introduction to Pan Curing: Traditional Skillet vs Blue Steel

Traditional skillets, often made of cast iron, provide excellent heat retention and distribution, making them ideal for curing processes that require steady temperatures. Blue steel pans, treated with a protective layer, offer quicker heating and a lighter weight, allowing for more responsive temperature control during curing.

Choosing between a traditional skillet and a blue steel pan depends on the specific curing technique and heat precision needed. Both types enhance the curing outcome by delivering consistent heat, but blue steel pans excel in agility while traditional skillets provide robust, even warmth.

Material Composition: Traditional Skillet and Blue Steel Pan

Traditional skillets are commonly made from cast iron, known for excellent heat retention and durability, making them ideal for even curing processes. Blue steel pans consist of carbon steel with a blue oxide layer, offering faster heat response and a smooth non-stick surface that enhances curing quality. The distinct material compositions affect heat distribution and seasoning, influencing how each pan performs during curing tasks.

Heat Distribution and Retention Comparison

Traditional cast iron skillets offer excellent heat retention, allowing for even curing and consistent temperature maintenance throughout the cooking process. Blue steel pans heat up more quickly but retain heat less effectively, which can cause temperature fluctuations during curing.

Cast iron's superior heat distribution reduces hot spots, ensuring uniform curing of ingredients such as meats and vegetables. Blue steel pans require more careful temperature control to avoid uneven curing, especially during prolonged heat exposure. Choosing between the two depends on the desired balance between quick heating and sustained, stable temperatures for optimal curing results.

Initial Curing Process: Step-by-Step Guide

The initial curing process for traditional skillets involves applying a thin layer of oil and heating it until it polymerizes, creating a non-stick surface. Blue steel pans require a similar but more delicate curing approach due to their tendency to rust, emphasizing thorough drying between coats.

Start by washing the pan with hot water and a mild detergent, then dry it completely to prevent moisture buildup. Apply a thin coat of high-smoke point oil and heat the pan on medium heat for 10-15 minutes, repeating the cycle 3-4 times for both pan types to build a durable seasoning layer.

Oil Absorption and Nonstick Qualities

Traditional skillets tend to absorb more oil during the curing process, which enhances their seasoning but may require frequent maintenance to prevent sticking. Blue steel pans, known for their superior nonstick qualities, develop a smooth surface with less oil absorption, making them easier to clean and maintain over time.

- Oil Absorption in Traditional Skillets - Traditional cast iron skillets absorb oil deeply, creating a robust seasoning layer that improves with use.

- Nonstick Qualities of Blue Steel Pans - Blue steel pans form a hard, slick patina that reduces food sticking without needing excessive oil.

- Maintenance Requirements - Traditional skillets require regular oiling to maintain their nonstick surface, while blue steel pans need less frequent seasoning.

Choosing between a traditional skillet and a blue steel pan depends on the balance of oil absorption and desired ease of maintenance during curing.

Durability and Longevity in Everyday Use

| Traditional Skillet Durability | Cast iron traditional skillets are known for their exceptional durability and can last a lifetime with proper seasoning and maintenance. They resist warping and high heat damage, making them ideal for regular curing processes that demand consistent temperature control. |

| Blue Steel Pan Longevity | Blue steel pans offer a balance of durability and lighter weight but require frequent seasoning to maintain their longevity and prevent rust. Their fast heat conduction supports even curing, but daily use may accelerate wear if not carefully cared for. |

| Comparison in Everyday Use | For curing, traditional skillets excel in long-term durability with minimal maintenance, whereas blue steel pans provide quicker heating but need more diligent upkeep to preserve their lifespan under everyday use conditions. |

Flavor Enhancement: Effect of Each Pan During Curing

Traditional cast iron skillets develop a natural seasoning over time that enhances flavor through the curing process, providing a rich, complex taste to food. Blue steel pans, with their smooth surface and rapid heat conduction, offer a more neutral curing environment, preserving the natural flavors without imparting additional seasoning notes. The choice between these pans significantly impacts the depth and character of flavor augmentation during curing.

Maintenance and Recurring Curing Needs

How do maintenance requirements differ between a traditional skillet and a blue steel pan for curing? Traditional skillets often require less frequent seasoning but can develop sticky residues that demand thorough cleaning after each use. Blue steel pans need regular oiling and curing to maintain their non-stick surface and prevent rust, making recurring maintenance more involved.

Common Pitfalls in Curing Both Pans

Common pitfalls in curing both traditional skillets and blue steel pans include uneven heat distribution and inadequate seasoning, which can affect the curing process and pan performance. Moisture retention during curing often leads to rust formation if not properly controlled.

- Uneven Heat Distribution - Both pans can develop hotspots that cause inconsistent curing and potential warping.

- Inadequate Seasoning - Failure to properly season leads to food sticking and diminished non-stick properties.

- Moisture Retention - Residual moisture during curing promotes rust, especially in blue steel pans without thorough drying.

Related Important Terms

Thermo-reactive seasoning

Traditional cast iron skillets develop a durable, thermo-reactive seasoning through repeated heating and oil polymerization, creating a natural non-stick surface ideal for curing processes. Blue steel pans, with their smoother finish and thinner construction, achieve a faster but less robust seasoning, requiring more frequent maintenance to maintain optimal curing performance.

Polymerized bacon fat layer

Traditional skillets develop a natural polymerized bacon fat layer through repeated seasoning, enhancing non-stick properties and flavor infusion during curing. Blue steel pans, with their smoother surfaces, also form this polymerized layer quickly, providing superior heat retention and even curing compared to cast iron.

Blue steel micro-seasoning

Blue steel pans develop a natural, durable non-stick surface through micro-seasoning, creating a protective layer that enhances flavor retention and improves curing effectiveness by preventing oxidation. Unlike traditional skillets, blue steel's micro-seasoned surface offers superior heat distribution and long-lasting seasoning that intensifies over time, making it ideal for consistent curing results.

Legacy cast iron patina

Traditional cast iron skillets develop a durable, non-stick legacy patina through repeated curing, enhancing flavor and heat retention over time. Blue steel pans require more frequent seasoning to maintain their protective layer, lacking the same long-term patina benefit seen in well-maintained cast iron cookware.

Quick oxidize pre-treatment

Traditional skillets require seasoning with oil to create a protective non-stick layer, but blue steel pans benefit from a quick oxidize pre-treatment that forms a durable, rust-resistant patina faster. This accelerated oxidation process enhances the pan's durability and improves curing efficiency by reducing the time needed to achieve an optimal surface for food preparation.

Rolling-bluing method

The traditional skillet, often made of cast iron, heats unevenly and lacks the precise surface layer essential for effective curing, whereas the blue steel pan, produced using the rolling-bluing method, features a smooth, tightly bonded oxide layer that enhances heat retention and promotes superior seasoning. The rolling-bluing process creates a durable, corrosion-resistant finish that improves the pan's reactivity and longevity, making it ideal for consistent curing results in culinary applications.

High-carbon seasoning myth

Traditional cast iron skillets and blue steel pans both develop seasoning through high-carbon content, but the myth that high-carbon alone ensures superior curing is misleading; proper seasoning depends more on polymerized oils and consistent heat application. Blue steel pans offer faster seasoning due to thinner metal and quicker temperature changes, while cast iron retains heat longer, influencing the curing process and seasoning durability differently.

Hybrid skillet cross-curing

Hybrid skillet cross-curing combines the durability of traditional cast iron skillets with the quick heat response of blue steel pans, optimizing seasoning layers for enhanced non-stick performance. This technique promotes even oil polymerization and improved rust resistance, resulting in a versatile cooking surface ideal for high-temperature searing and delicate frying.

Enzymatic pre-cure rub

Traditional skillets often lack the ideal surface properties for enzymatic pre-cure rub application, resulting in uneven curing and flavor development. Blue steel pans, with their superior heat retention and smooth finish, enhance enzymatic activity, promoting consistent curing and deeper infusion of rub flavors.

Traditional skillet vs blue steel pan for curing. Infographic

cookingdiff.com

cookingdiff.com