Pack curing involves using a dry mixture of salt, sugar, and nitrates directly applied to the meat, promoting flavor development and preservation through diffusion over time. Transglutaminase curing utilizes the enzyme to bind proteins in the meat, improving texture and cohesion without relying solely on salt and nitrates. This method provides a more uniform product with enhanced structural integrity, making it ideal for intricate charcuterie presentations where appearance and sliceability are critical.

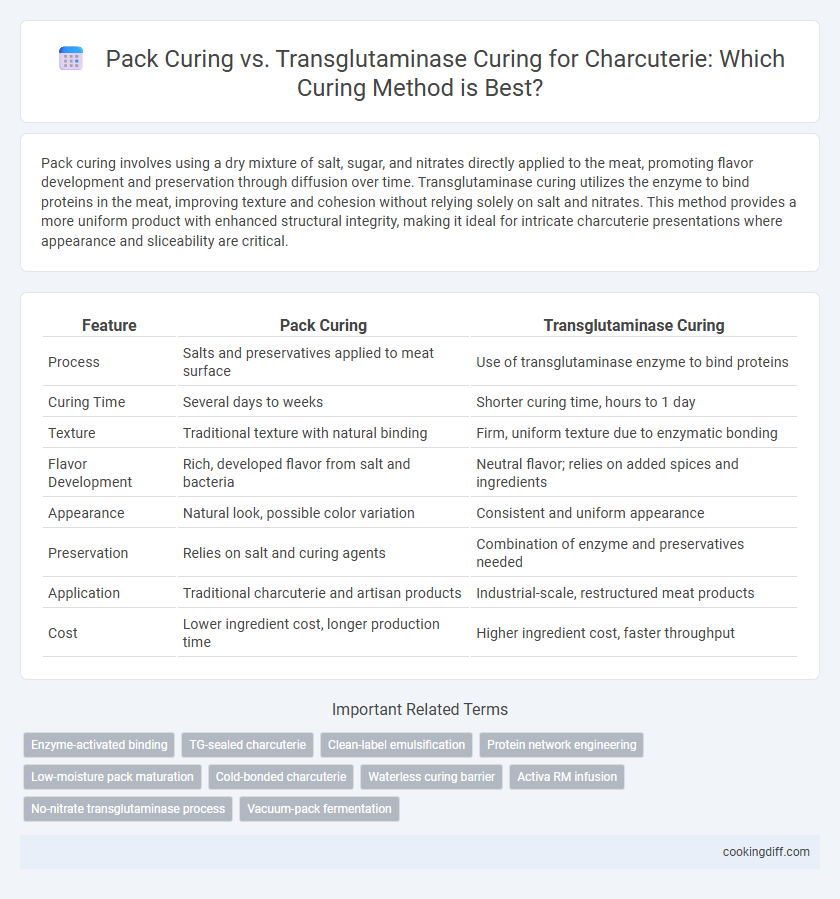

Table of Comparison

| Feature | Pack Curing | Transglutaminase Curing |

|---|---|---|

| Process | Salts and preservatives applied to meat surface | Use of transglutaminase enzyme to bind proteins |

| Curing Time | Several days to weeks | Shorter curing time, hours to 1 day |

| Texture | Traditional texture with natural binding | Firm, uniform texture due to enzymatic bonding |

| Flavor Development | Rich, developed flavor from salt and bacteria | Neutral flavor; relies on added spices and ingredients |

| Appearance | Natural look, possible color variation | Consistent and uniform appearance |

| Preservation | Relies on salt and curing agents | Combination of enzyme and preservatives needed |

| Application | Traditional charcuterie and artisan products | Industrial-scale, restructured meat products |

| Cost | Lower ingredient cost, longer production time | Higher ingredient cost, faster throughput |

Introduction to Charcuterie Curing Methods

What are the primary differences between pack curing and transglutaminase curing in charcuterie? Pack curing involves applying a dry mixture of salt, nitrates, and spices directly to the meat surface to draw out moisture and preserve the product. Transglutaminase curing utilizes an enzyme to bind proteins, improving texture and allowing for uniform curing in sliced or formed meats.

What is Pack Curing?

| Pack Curing is a traditional meat preservation method involving packing charcuterie in a dry curing mixture of salt, sugar, and nitrates to inhibit bacterial growth and enhance flavor. |

| This technique relies on osmosis to draw moisture out of the meat, creating an environment hostile to spoilage and promoting a firm texture. |

| Pack curing is preferred for its simplicity and ability to develop complex flavors over time without chemical additives like enzymes used in transglutaminase curing. |

Understanding Transglutaminase Curing

Transglutaminase curing involves the enzymatic binding of proteins to improve texture and moisture retention in charcuterie. This method enhances firmness and sliceability without relying heavily on salt or nitrates.

Compared to traditional pack curing, transglutaminase curing allows for precise control over product consistency and reduces curing time. The enzyme creates stronger protein networks by catalyzing cross-links between glutamine and lysine residues. This results in improved structural integrity and a desirable mouthfeel in cured meats.

Science Behind Pack Curing

Pack curing involves immersing meat in a high-salt mixture that inhibits bacterial growth by creating a hypertonic environment, effectively drawing out moisture to preserve the product. The science behind pack curing relies on osmosis and salt's ability to denature proteins, thereby enhancing flavor and texture while extending shelf life. This method contrasts with transglutaminase curing, which uses the enzyme to bind proteins chemically rather than relying on salt's preservation properties.

Science Behind Transglutaminase Curing

Transglutaminase curing enhances protein cross-linking in charcuterie, improving texture and binding without added salt. This enzymatic process offers a scientific advantage over traditional pack curing by promoting uniform meat cohesion and moisture retention.

- Enzymatic Action - Transglutaminase catalyzes covalent bonds between glutamine and lysine residues in meat proteins, creating a stable matrix.

- Texture Improvement - The enzyme-induced cross-linking results in enhanced firmness and sliceability of charcuterie products.

- Moisture Retention - By binding water within the protein network, transglutaminase curing reduces drip loss and enhances juiciness.

Differences in Flavor Development

Pack curing preserves the natural flavors of meats by using traditional salt and spice blends, promoting slow and even flavor penetration. Transglutaminase curing enhances texture and firmness but tends to produce a milder flavor profile due to enzymatic binding rather than seasoning absorption. The primary distinction lies in pack curing's richer, more pronounced taste compared to the subtle, uniform flavor resulting from transglutaminase treatment.

Texture and Appearance Comparison

Pack curing enhances the texture of charcuterie by promoting even moisture distribution, resulting in a firm yet tender bite. This method also contributes to a visually uniform appearance with consistent color throughout the product.

Transglutaminase curing improves texture by binding proteins, creating a cohesive and elastic structure ideal for complex shapes. The appearance is often glossy and smooth, giving charcuterie an artisanal, refined look that appeals to premium markets.

Safety and Shelf Life Considerations

Pack curing involves using vacuum-sealed packaging to limit oxygen exposure, which reduces the risk of microbial growth and enhances shelf life stability for charcuterie products. This method supports maintaining flavor integrity and safety by creating an anaerobic environment that inhibits spoilage organisms.

Transglutaminase curing employs the enzyme transglutaminase to bind proteins, improving texture and water retention without relying solely on preservatives. Shelf life considerations focus on proper refrigeration and hygiene, as enzymatic curing alone does not extend microbial safety compared to pack curing techniques.

Practical Applications in Charcuterie Making

Pack curing involves applying a dry or wet cure directly to meat surfaces, ensuring traditional flavor absorption and preservation, while transglutaminase curing uses enzymes to bind proteins, enhancing texture and sliceability in charcuterie products. Both methods offer unique benefits in texture modification and flavor development essential for artisanal and industrial charcuterie production.

- Pack curing enhances flavor - The direct cure application allows spices and salts to deeply penetrate the meat, developing traditional charcuterie profiles.

- Transglutaminase improves texture - This enzyme binds proteins, creating firmer, sliceable products ideal for uniform appearance in deli meats.

- Practical use depends on product - Pack curing suits authentic dry-cured sausages, while transglutaminase is favored for composite or restructured meat items.

Related Important Terms

Enzyme-activated binding

Pack curing relies on salt and time to develop texture and flavor, while transglutaminase curing utilizes the enzyme transglutaminase to catalyze protein cross-linking, enhancing binding strength and uniformity in charcuterie products. Enzyme-activated binding through transglutaminase improves product cohesion and sliceability compared to traditional pack curing methods.

TG-sealed charcuterie

TG-sealed charcuterie uses transglutaminase enzymes to bind proteins, creating a cohesive texture and improved sliceability that traditional pack curing methods often cannot achieve. This enzymatic curing enhances moisture retention and flavor integration, resulting in a superior product with consistent quality and extended shelf life.

Clean-label emulsification

Pack curing offers a natural preservation method relying on salt and nitrates, enhancing flavor and texture without artificial additives, while transglutaminase curing uses enzyme-induced protein cross-linking to improve emulsification and sliceability in charcuterie. Clean-label emulsification benefits from transglutaminase by reducing the need for synthetic stabilizers, resulting in a cleaner ingredient list that appeals to health-conscious consumers.

Protein network engineering

Pack curing enhances charcuterie texture through controlled salt and nitrate diffusion that stabilizes proteins and promotes water retention, while transglutaminase curing specifically catalyzes covalent cross-linking of glutamine and lysine residues, resulting in a stronger and more elastic protein network for improved sliceability and firmness. Transglutaminase's enzymatic action allows precision in protein network engineering, offering consistent product quality and reduced reliance on traditional curing agents.

Low-moisture pack maturation

Low-moisture pack maturation in charcuterie achieves enhanced flavor and texture by controlling moisture loss and microbial growth through vacuum-sealed aging. Transglutaminase curing offers precise protein bonding for texture improvement but lacks the extended flavor development found in traditional pack curing methods.

Cold-bonded charcuterie

Pack curing utilizes vacuum-sealed packaging combined with controlled temperature to promote cold bonding, preserving the texture and flavor integrity of charcuterie without heat exposure. Transglutaminase curing employs an enzyme that catalyzes protein cross-linking at low temperatures, enhancing structural cohesion and sliceability in cold-bonded charcuterie products.

Waterless curing barrier

Pack curing creates a waterless curing barrier by tightly sealing the meat in vacuum-packed films, effectively preventing moisture loss while allowing the curing agents to penetrate uniformly. Transglutaminase curing enhances protein bonding, improving texture and sliceability, but relies on enzymatic action rather than forming a direct moisture-retentive barrier like pack curing.

Activa RM infusion

Activa RM infusion enhances Pack Curing by uniformly distributing curing agents, resulting in improved texture and reduced processing time for charcuterie products. Transglutaminase Curing, while effective for protein binding, lacks the infusion efficiency of Activa RM, making Pack Curing the preferred method for consistent flavor development and product stability.

No-nitrate transglutaminase process

No-nitrate transglutaminase curing enhances charcuterie by cross-linking proteins to improve texture and binding without the use of traditional nitrates or nitrites, reducing potential health concerns. This enzymatic method preserves flavor and moisture while providing a cleaner label alternative compared to pack curing, which relies on chemical additives for preservation and color stabilization.

Pack Curing vs Transglutaminase Curing for charcuterie. Infographic

cookingdiff.com

cookingdiff.com