Seasoned cast iron develops a natural non-stick surface through repeated oil polymerization, making it ideal for curing pans with traditional flavors and durability. Nitrided cast iron undergoes a surface hardening process that enhances corrosion resistance and reduces wear, offering a more maintenance-free option for curing without compromising pan longevity. Choosing between seasoned and nitrided cast iron depends on the desired balance between authentic seasoning development and ease of upkeep during the curing process.

Table of Comparison

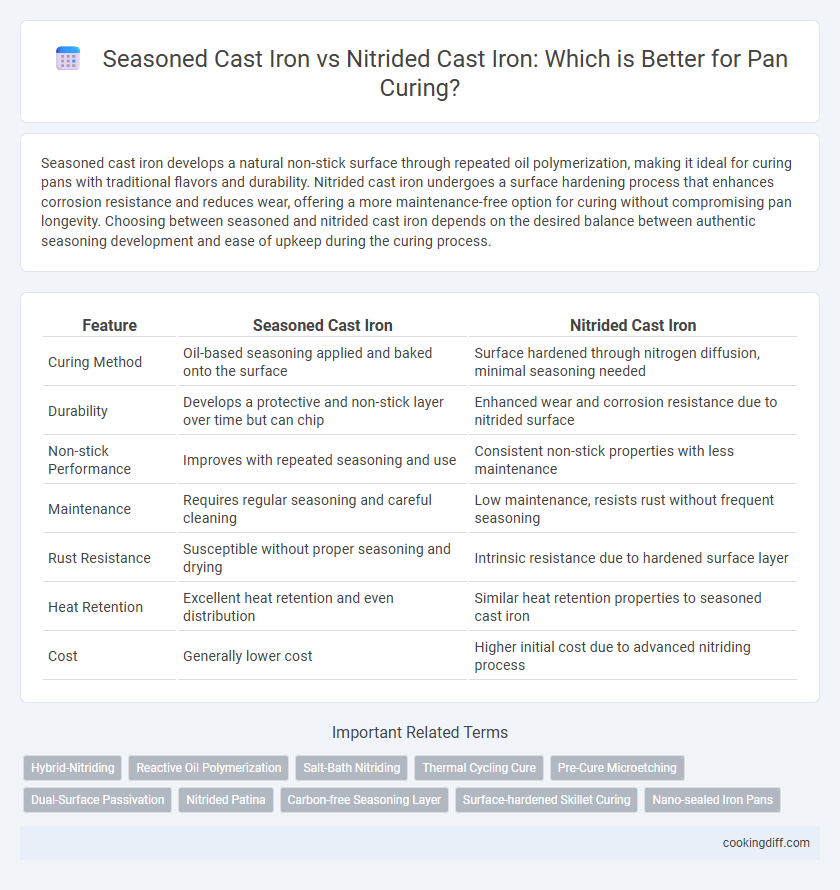

| Feature | Seasoned Cast Iron | Nitrided Cast Iron |

|---|---|---|

| Curing Method | Oil-based seasoning applied and baked onto the surface | Surface hardened through nitrogen diffusion, minimal seasoning needed |

| Durability | Develops a protective and non-stick layer over time but can chip | Enhanced wear and corrosion resistance due to nitrided surface |

| Non-stick Performance | Improves with repeated seasoning and use | Consistent non-stick properties with less maintenance |

| Maintenance | Requires regular seasoning and careful cleaning | Low maintenance, resists rust without frequent seasoning |

| Rust Resistance | Susceptible without proper seasoning and drying | Intrinsic resistance due to hardened surface layer |

| Heat Retention | Excellent heat retention and even distribution | Similar heat retention properties to seasoned cast iron |

| Cost | Generally lower cost | Higher initial cost due to advanced nitriding process |

Understanding Cast Iron: Seasoned vs Nitrided

Seasoned cast iron pans develop a natural non-stick surface through repeated oil curing, which polymerizes and bonds to the pan's surface. Nitrided cast iron undergoes a heat treatment process that diffuses nitrogen into the metal, enhancing hardness, corrosion resistance, and reducing the need for frequent seasoning. Understanding the differences between these two methods helps determine maintenance requirements and cooking performance for optimal pan longevity.

What Is Seasoned Cast Iron?

Seasoned cast iron refers to cast iron cookware that has developed a natural non-stick coating through repeated applications of oil and heat. This layer not only enhances cooking performance but also protects the pan from rust and corrosion.

- Natural non-stick surface - Achieved by polymerizing oils into the cast iron pores through heating.

- Rust prevention - The seasoning layer acts as a protective barrier against moisture and oxidation.

- Improved cooking flavor - Seasoned cast iron pans enhance food taste by providing even heat distribution.

What Is Nitrided Cast Iron?

Nitrided cast iron is a type of cast iron that has undergone a nitriding process, where nitrogen atoms diffuse into the surface, enhancing hardness and corrosion resistance. This treatment creates a durable, wear-resistant layer ideal for cookware like frying pans.

The nitriding process improves the pan's ability to withstand rust and reduces the need for frequent seasoning compared to traditional cast iron. It results in a smoother surface that maintains non-stick properties over time. Nitrided cast iron pans are favored for their low maintenance and long-lasting performance in kitchen use.

Curing Process for Seasoned Cast Iron

The curing process for seasoned cast iron involves coating the pan with a thin layer of oil and heating it to polymerize the oil, creating a natural, non-stick surface. This seasoning layer enhances corrosion resistance and improves cooking performance over time with repeated applications.

Nitrided cast iron, while benefiting from surface hardening through nitrogen diffusion, does not rely on polymerized oil for curing but instead gains durability from its treated surface. Seasoned cast iron requires regular maintenance and re-seasoning to sustain its protective coating and optimal cooking properties.

Curing Process for Nitrided Cast Iron

The curing process for nitrided cast iron pans involves a specialized heat treatment that enhances surface hardness and corrosion resistance without compromising the iron's thermal conductivity. Unlike seasoned cast iron, nitrided cast iron undergoes nitrogen diffusion, creating a hard, wear-resistant layer that requires minimal seasoning.

- Nitrogen Diffusion - The casting is exposed to a nitrogen-rich environment at high temperatures to form a hardened surface layer.

- Reduced Seasoning Requirement - The nitrided surface is less porous, allowing for faster and more durable curing compared to traditional seasoning.

- Corrosion Resistance - The nitrided layer protects against rust, reducing the need for frequent oil applications during curing.

This curing process results in a low-maintenance pan that maintains non-stick properties and durability over time.

Heat Resistance: Seasoned vs Nitrided Cast Iron

How does heat resistance compare between seasoned cast iron and nitrided cast iron during pan curing? Seasoned cast iron develops a natural non-stick layer through polymerized oils but may degrade under extreme heat over time. Nitrided cast iron undergoes surface hardening that improves heat tolerance and durability, making it more resistant to thermal stress and warping during curing.

Nonstick Properties and Performance

Seasoned cast iron pans develop a natural nonstick surface through polymerized oil layers, enhancing cooking performance and flavor retention over time. This traditional curing process requires regular maintenance to maintain its effective nonstick properties and prevent rust.

Nitrided cast iron pans undergo a surface treatment that forms a hard, corrosion-resistant layer, offering superior durability and an inherently smoother surface for improved nonstick performance. This method reduces the need for frequent seasoning and provides consistent cooking results with less effort in upkeep.

Durability and Longevity Comparison

| Material Type | Durability | Longevity |

|---|---|---|

| Seasoned Cast Iron | Develops a natural, non-stick layer through repeated seasoning; prone to rust if not maintained properly. | Can last decades with proper care; seasoning layers can wear off requiring re-curing over time. |

| Nitrided Cast Iron | Enhanced surface hardness and corrosion resistance due to nitrogen diffusion; less prone to flaking or rust. | Offers superior longevity with minimal maintenance; seasoning layers remain stable longer under heavy use. |

Maintenance and Re-seasoning Needs

Seasoned cast iron pans require regular maintenance including cleaning and periodic re-seasoning to maintain their non-stick surface and prevent rust. Nitrided cast iron offers enhanced durability with less frequent re-seasoning needed due to its harder, chemically treated surface.

- Seasoned Cast Iron Maintenance - Needs regular oiling and heating after each use to preserve the seasoning layer and avoid rusting.

- Nitrided Cast Iron Durability - The nitriding process creates a tough, corrosion-resistant surface that minimizes the frequency of re-seasoning.

- Re-seasoning Frequency - Seasoned cast iron pans typically require re-seasoning every few months, while nitrided cast iron can go much longer between treatments due to its stable surface.

Related Important Terms

Hybrid-Nitriding

Hybrid-nitriding combines the wear resistance and corrosion protection of nitrided cast iron with the enhanced seasoning ability typical of seasoned cast iron, offering superior durability and non-stick performance for pan curing. This process creates a robust, nitrogen-enriched surface layer that promotes even heat distribution while allowing a natural polymerized oil layer to bond effectively, optimizing the cooking surface's longevity.

Reactive Oil Polymerization

Seasoned cast iron relies on reactive oil polymerization to build a durable, non-stick layer through repeated heating of oils that chemically bond to the pan's surface, whereas nitrided cast iron offers a harder, more corrosion-resistant surface that requires less maintenance but develops a thinner seasoning layer. The polymerization process in seasoned cast iron forms a robust, carbon-rich coating, enhancing non-stick properties and pan longevity compared to the more physically altered surface of nitrided cast iron.

Salt-Bath Nitriding

Salt-bath nitriding significantly enhances the surface hardness and corrosion resistance of cast iron pans compared to traditional seasoning methods used on seasoned cast iron, resulting in superior durability and reduced maintenance. This thermochemical treatment creates a uniform, wear-resistant nitride layer that improves pan longevity and heat retention, making nitrided cast iron pans more efficient and long-lasting cookware options.

Thermal Cycling Cure

Seasoned cast iron develops a natural non-stick patina through repeated thermal cycling, enhancing its corrosion resistance and cooking performance; nitrided cast iron undergoes a controlled heat treatment that diffuses nitrogen into the surface, creating a harder, more wear-resistant layer that improves thermal cycling durability and reduces oxidation during curing. Thermal cycling cure in nitrided cast iron results in a stable, corrosion-resistant surface with superior heat retention and faster seasoning buildup compared to traditional seasoned cast iron pans.

Pre-Cure Microetching

Pre-cure microetching enhances seasoning adherence by increasing surface roughness, crucial for durable coatings on both seasoned and nitrided cast iron pans. Nitrided cast iron benefits more from pre-cure microetching due to its hardened surface, promoting superior seasoning durability compared to traditional seasoned cast iron.

Dual-Surface Passivation

Seasoned cast iron develops a natural non-stick layer through polymerized oil, enhancing heat retention and flavor over time, while nitrided cast iron undergoes a dual-surface passivation, creating a hardened, corrosion-resistant layer that improves durability and reduces seasoning maintenance. Dual-surface passivation in nitrided pans offers superior protection against rust and wear without relying solely on oil seasoning, making it ideal for long-lasting cookware performance.

Nitrided Patina

Nitrided cast iron develops a durable nitrided patina through a surface hardening process that enhances corrosion resistance and creates a non-stick layer faster than traditional seasoning methods used on seasoned cast iron. This nitrided patina significantly reduces maintenance by preventing rust and improving the pan's overall longevity and cooking performance.

Carbon-free Seasoning Layer

Seasoned cast iron develops a carbon-rich seasoning layer through polymerized oils, which enhances non-stick properties but may retain carbon deposits affecting durability. Nitrided cast iron forms a hard, carbon-free surface via nitrogen diffusion, offering superior corrosion resistance and a more stable base for seasoning layers without carbon contamination.

Surface-hardened Skillet Curing

Seasoned cast iron pans develop a natural non-stick surface through the polymerization of oils during curing, enhancing flavor and durability, while nitrided cast iron features a surface-hardened layer created by nitrogen diffusion, improving corrosion resistance and wear without sacrificing seasoning properties. Surface-hardened skillet curing on nitrided cast iron offers superior longevity and maintenance ease, making it a preferred choice for chefs seeking enhanced performance and minimal upkeep.

Seasoned Cast Iron vs Nitrided Cast Iron for pan curing. Infographic

cookingdiff.com

cookingdiff.com