Plastic brining containers offer affordability and lightweight convenience for curing, yet they may absorb odors and stain over time, affecting the purity of the brine. Food-grade stainless brining tanks ensure durability, resistance to corrosion, and easy sanitation, making them ideal for consistent and safe curing processes. Selecting stainless steel tanks enhances flavor integrity and supports long-term use in both home and commercial curing environments.

Table of Comparison

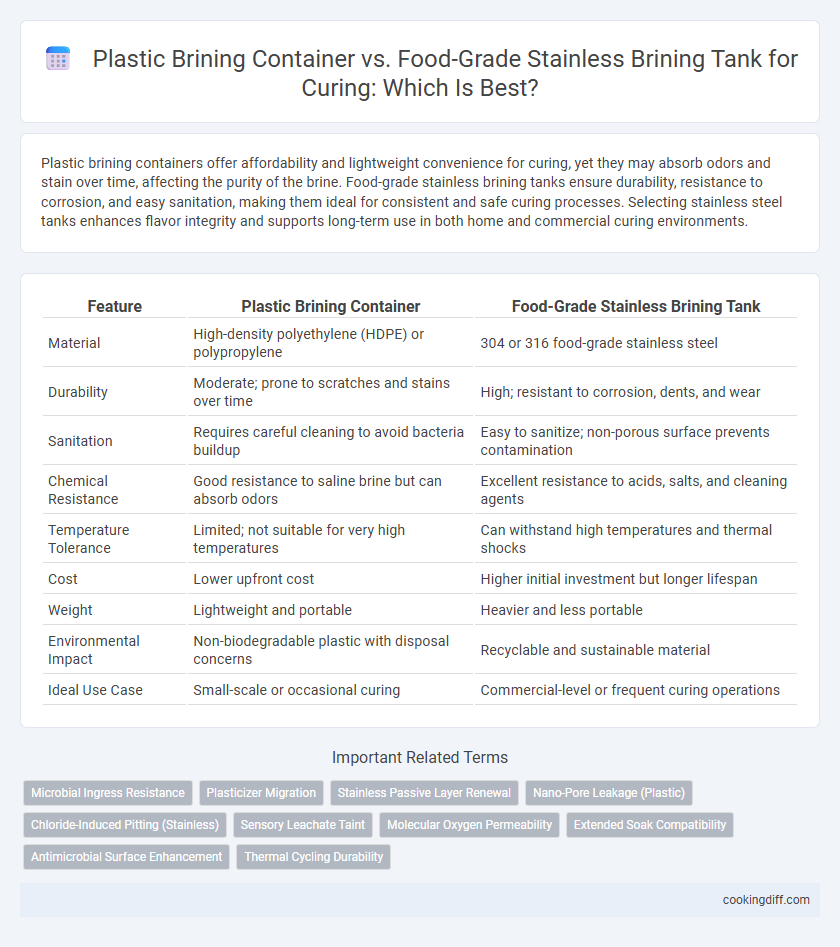

| Feature | Plastic Brining Container | Food-Grade Stainless Brining Tank |

|---|---|---|

| Material | High-density polyethylene (HDPE) or polypropylene | 304 or 316 food-grade stainless steel |

| Durability | Moderate; prone to scratches and stains over time | High; resistant to corrosion, dents, and wear |

| Sanitation | Requires careful cleaning to avoid bacteria buildup | Easy to sanitize; non-porous surface prevents contamination |

| Chemical Resistance | Good resistance to saline brine but can absorb odors | Excellent resistance to acids, salts, and cleaning agents |

| Temperature Tolerance | Limited; not suitable for very high temperatures | Can withstand high temperatures and thermal shocks |

| Cost | Lower upfront cost | Higher initial investment but longer lifespan |

| Weight | Lightweight and portable | Heavier and less portable |

| Environmental Impact | Non-biodegradable plastic with disposal concerns | Recyclable and sustainable material |

| Ideal Use Case | Small-scale or occasional curing | Commercial-level or frequent curing operations |

Understanding Brining: The Role of Containers in Curing

Plastic brining containers offer lightweight, cost-effective solutions with non-reactive surfaces ideal for small-scale curing, while food-grade stainless steel tanks provide durability, corrosion resistance, and ease of sanitation for large-scale or commercial applications. The choice of container material impacts the brine's chemical stability, preventing contamination and ensuring consistent flavor penetration during the curing process. Understanding container properties helps maintain optimal temperature and hygiene, critical factors that influence the quality and safety of cured products.

Plastic Brining Containers: Features and Advantages

Plastic brining containers offer a lightweight and cost-effective solution for curing meats and other foods. They resist corrosion and are easy to clean, making them ideal for various curing processes.

- Food-Safe Material - Made from BPA-free, FDA-approved plastic to ensure safe contact with curing ingredients.

- Portability - Lightweight design allows for easy handling and transportation within production areas.

- Durability - Resistant to rust, dents, and impact compared to metal alternatives.

Plastic brining containers provide excellent value for small to medium-scale curing operations seeking efficiency and food safety.

Food-Grade Stainless Brining Tanks: Key Benefits

Food-grade stainless brining tanks offer superior durability and resistance to corrosion compared to plastic brining containers, ensuring long-term use without contamination risks. Their non-porous surface prevents bacterial growth, making them ideal for maintaining food safety during the curing process.

- Enhanced Hygiene - Stainless steel's smooth, non-porous surface inhibits bacterial buildup, supporting safer food curing.

- Durability - Resistant to corrosion and physical wear, stainless tanks last significantly longer than plastic alternatives.

- Improved Temperature Control - Stainless steel facilitates even temperature distribution, optimizing the curing environment.

Safety Considerations: Food-Grade Certifications

Plastic brining containers must have FDA-approved food-grade certifications to ensure no harmful chemicals leach during the curing process. Food-grade stainless brining tanks, often certified by NSF and FDA standards, provide a non-reactive surface that prevents contamination and maintains product integrity.

Food-grade stainless steel is resistant to corrosion and easy to sanitize, making it ideal for prolonged curing periods without compromising safety. Plastic containers lacking proper certifications may pose risks of chemical migration, especially when exposed to salt and curing agents. Selecting certified food-grade materials guarantees compliance with safety regulations and protects the quality of the cured foods.

Durability and Longevity: Plastic vs Stainless Steel

Food-grade stainless steel brining tanks offer superior durability and longevity compared to plastic brining containers, resisting corrosion and damage from repeated exposure to salty curing solutions. Stainless steel's non-porous surface prevents bacterial contamination and eliminates staining or warping, which commonly affects plastic containers over time. While plastic brining containers may be cost-effective initially, their susceptibility to cracks and odor retention significantly reduces their usable lifespan in curing applications.

Ease of Cleaning and Maintenance

Plastic brining containers are lightweight and non-porous, making them easy to clean with standard detergents and dishwasher safe options. Their resistance to corrosion prevents buildup, reducing maintenance frequency.

Food-grade stainless steel brining tanks offer superior durability and resist staining or odor retention, simplifying deep cleaning processes. However, they require occasional polishing and inspection to prevent surface damage and ensure long-term hygiene.

Impact on Flavor and Curing Quality

Plastic brining containers are affordable and lightweight but can absorb odors and stains, potentially impacting the purity of flavor during curing. Food-grade stainless steel brining tanks provide a non-reactive surface that maintains the true taste and quality of cured foods without leaching any unwanted flavors.

Stainless steel tanks also offer better durability and resistance to bacteria, ensuring a more consistent and hygienic curing environment. Plastic containers may degrade over time, which can compromise curing quality and affect the final product's flavor profile negatively.

Cost Comparison: Upfront and Long-Term Investment

Plastic brining containers typically require a lower upfront investment compared to food-grade stainless steel brining tanks, making them more accessible for small-scale operations. Over time, stainless steel tanks offer greater durability and lower maintenance costs, resulting in better long-term value.

- Plastic containers are cost-effective initially - They usually cost significantly less upfront, ideal for budget-conscious buyers.

- Stainless steel tanks have higher longevity - Resistance to corrosion and wear reduces replacement frequency and associated costs.

- Maintenance costs differ substantially - Plastic containers may require more frequent cleaning or replacement, increasing expenses over time.

Practical Uses: Home vs Commercial Curing

| Plastic Brining Container | Ideal for home curing due to its lightweight design and affordability, making it easy to handle and clean. Suitable for small batches of meat or vegetables, it resists corrosion but may retain odors over time. Typically available in sizes ranging from 1 to 10 gallons, perfect for occasional use by home cooks. |

| Food-Grade Stainless Brining Tank | Preferred in commercial curing settings because of its durability, resistance to corrosion, and non-porous surface that prevents bacterial growth. Supports large-scale brining processes with sizes extending up to 100 gallons or more, ensuring consistent flavor absorption and safety compliance. Easier to sanitize and maintain for frequent use in professional kitchens or food processing plants. |

Related Important Terms

Microbial Ingress Resistance

Food-grade stainless brining tanks offer superior resistance to microbial ingress due to their non-porous surfaces and seamless construction, minimizing contamination risks during the curing process. In contrast, plastic brining containers may develop micro-scratches and pores over time, increasing the likelihood of bacterial growth and compromising food safety.

Plasticizer Migration

Plastic brining containers risk plasticizer migration, which can leach harmful chemicals into the curing solution and compromise food safety. Food-grade stainless steel brining tanks provide a non-reactive, durable alternative that prevents plastic contamination and maintains product purity during the curing process.

Stainless Passive Layer Renewal

Food-grade stainless brining tanks offer superior durability in curing processes due to their passive layer renewal, which continuously protects against corrosion and contamination. Unlike plastic brining containers, stainless tanks maintain structural integrity and ensure consistent sanitary conditions, enhancing food safety and product quality.

Nano-Pore Leakage (Plastic)

Plastic brining containers often suffer from nano-pore leakage, allowing small amounts of brine and contaminants to escape or seep in, which can compromise the curing process and affect food safety. In contrast, food-grade stainless steel brining tanks provide a non-porous, corrosion-resistant surface that ensures airtight conditions, preventing leakage and maintaining optimal curing quality.

Chloride-Induced Pitting (Stainless)

Food-grade stainless brining tanks offer superior durability and resistance to chemical damage compared to plastic brining containers, yet they remain vulnerable to chloride-induced pitting corrosion, especially when exposed to high-salinity curing solutions. Selecting stainless steel with a high molybdenum content and employing proper maintenance protocols can mitigate pitting risks while ensuring safe, long-term curing performance.

Sensory Leachate Taint

Plastic brining containers often risk sensory leachate taint due to chemical migration from plasticizers, compromising flavor and aroma during curing. Food-grade stainless steel brining tanks eliminate this risk by providing a non-reactive, inert surface that preserves the sensory integrity of cured products.

Molecular Oxygen Permeability

Food-grade stainless brining tanks exhibit significantly lower molecular oxygen permeability compared to plastic brining containers, reducing oxidative spoilage and preserving meat quality during curing. The impermeable stainless steel surface creates a more controlled environment that minimizes oxygen exposure, enhancing the effectiveness of the cure and extending shelf life.

Extended Soak Compatibility

Food-grade stainless brining tanks offer superior extended soak compatibility due to their corrosion resistance and non-reactive surface, ensuring consistent flavor absorption without contamination over long curing periods. Plastic brining containers may leach chemicals and degrade over time when used for extended soaks, compromising the curing process and food safety.

Antimicrobial Surface Enhancement

Food-grade stainless brining tanks offer superior antimicrobial surface enhancement compared to plastic brining containers due to their non-porous, corrosion-resistant properties that inhibit bacterial growth. Their seamless construction and ease of sanitation reduce contamination risks, ensuring safer and more effective curing processes.

Plastic Brining Container vs Food-Grade Stainless Brining Tank for Curing. Infographic

cookingdiff.com

cookingdiff.com