Smoke curing enhances ham's flavor by infusing it with smoky compounds and acts as a preservative through antimicrobial properties, while koji inoculation relies on enzymatic breakdown by mold to tenderize meat and develop umami-rich flavors. Smoke curing imparts a distinctive aroma and firm texture, whereas koji inoculation produces a more delicate texture with complex, savory notes from fermentation. Both methods preserve ham but differ fundamentally in flavor profiles and biochemical processes.

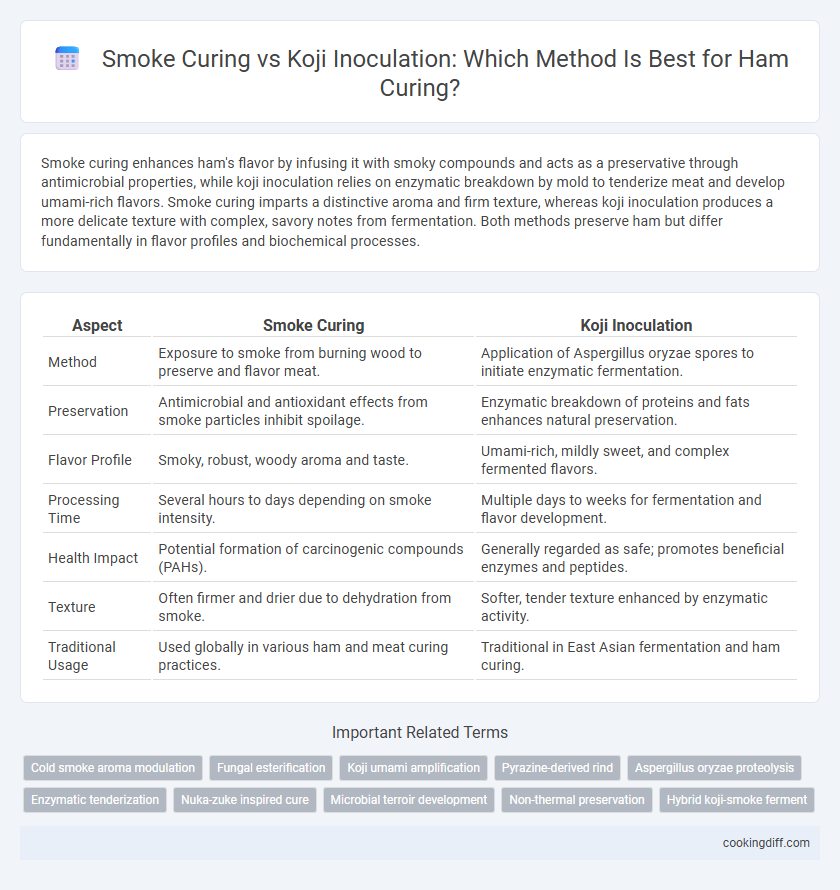

Table of Comparison

| Aspect | Smoke Curing | Koji Inoculation |

|---|---|---|

| Method | Exposure to smoke from burning wood to preserve and flavor meat. | Application of Aspergillus oryzae spores to initiate enzymatic fermentation. |

| Preservation | Antimicrobial and antioxidant effects from smoke particles inhibit spoilage. | Enzymatic breakdown of proteins and fats enhances natural preservation. |

| Flavor Profile | Smoky, robust, woody aroma and taste. | Umami-rich, mildly sweet, and complex fermented flavors. |

| Processing Time | Several hours to days depending on smoke intensity. | Multiple days to weeks for fermentation and flavor development. |

| Health Impact | Potential formation of carcinogenic compounds (PAHs). | Generally regarded as safe; promotes beneficial enzymes and peptides. |

| Texture | Often firmer and drier due to dehydration from smoke. | Softer, tender texture enhanced by enzymatic activity. |

| Traditional Usage | Used globally in various ham and meat curing practices. | Traditional in East Asian fermentation and ham curing. |

Introduction to Ham Curing Methods

Smoke curing imparts a distinctive flavor and preserves ham by exposing it to controlled smoke from burning wood, which also inhibits bacterial growth. Koji inoculation utilizes Aspergillus oryzae mold to enzymatically develop unique umami flavors during fermentation, enhancing ham texture and taste.

Traditional smoke curing relies on chemical reactions between smoke compounds and meat proteins, while koji inoculation promotes enzymatic breakdown of proteins and fats. Both methods serve to enhance preservation and flavor, yet target different biochemical processes critical to ham quality.

What Is Smoke Curing?

Smoke curing is a traditional preservation method that uses smoke from burning wood to infuse ham with flavor while inhibiting bacterial growth. This process can last from several hours to days depending on the desired taste and texture.

- Flavor Development - Smoke curing imparts a distinctive smoky aroma and taste derived from compounds in wood smoke.

- Preservation - The smoke acts as an antimicrobial agent, reducing spoilage by limiting harmful bacteria.

- Moisture Regulation - Smoke curing partially dehydrates the ham, contributing to its texture and shelf life.

Understanding Koji Inoculation in Curing

Koji inoculation in ham curing utilizes the mold Aspergillus oryzae to enzymatically break down proteins and fats, enhancing umami flavor and tenderness. This traditional Japanese fermentation technique accelerates maturation compared to conventional smoke curing methods.

Unlike smoke curing, which imparts smoky aromas through combustion byproducts, koji inoculation fosters complex biochemical transformations that improve texture and depth of taste without introducing smoke particles. The enzymes produced by koji mold stimulate proteolysis and lipolysis, critical processes for developing the characteristic softness and savory profile of cured ham. Koji inoculation also reduces the need for extended curing times, making it an efficient alternative for artisanal ham production.

Flavor Profiles: Smoke vs Koji

Smoke curing imparts a robust, smoky flavor with hints of wood and char, creating a deeply savory and aromatic profile in ham. Koji inoculation develops complex umami and subtle sweetness through enzymatic fermentation, enhancing tenderness and nuanced taste layers.

- Smoke Curing Flavor - Introduces phenolic compounds from wood smoke that penetrate the meat, resulting in a bold, smoky aroma.

- Koji Inoculation Flavor - Utilizes Aspergillus oryzae enzymes to break down proteins into amino acids, enriching the ham with umami and mild sweetness.

- Flavor Complexity - Smoke curing emphasizes bold, earthy notes while koji creates delicate, layered flavors through fermentation.

Texture Changes: Comparing Techniques

How do smoke curing and koji inoculation affect the texture of ham differently? Smoke curing imparts a firm, slightly chewy texture by dehydrating the meat and forming a smoky crust, enhancing the overall bite. Koji inoculation breaks down proteins and fats enzymatically, resulting in a tender, melt-in-the-mouth texture with a complex umami flavor profile.

Preservation and Shelf Life Differences

Smoke curing preserves ham by exposing it to smoke containing antimicrobial compounds, which inhibit bacterial growth and enhance shelf life for several months under proper storage conditions. The process also imparts a distinct smoky flavor and creates a surface barrier that reduces moisture loss.

Koji inoculation uses Aspergillus oryzae enzymes to ferment the ham, promoting biochemical changes that tenderize the meat while producing natural preservatives like organic acids. This method can extend shelf life by controlling spoilage organisms, but typically requires refrigeration and careful humidity management for optimal preservation.

Nutritional Impacts of Each Method

Smoke curing significantly increases antioxidant levels and imparts beneficial phenolic compounds to ham, enhancing its preservative qualities and flavor profile. Koji inoculation boosts the protein digestibility and enriches the ham with essential amino acids and vitamins, particularly B-complex vitamins. Both methods influence the nutritional profile differently, with smoke curing enhancing antioxidant content and koji inoculation improving enzymatic activity and nutrient bioavailability.

Traditional vs Innovative Curing Approaches

Smoke curing is a traditional method that imparts flavor and preserves ham through the application of smoke from burning wood, relying on natural antimicrobial properties and dehydration. Koji inoculation, an innovative approach, utilizes Aspergillus oryzae mold to enzymatically break down proteins and fats, enhancing umami flavor and accelerating the curing process. Comparing these techniques highlights smoke curing's deep-rooted cultural significance versus koji's potential for precision and novel taste profiles in modern ham production.

Safety Considerations in Ham Curing

| Smoke curing introduces antimicrobial compounds like formaldehyde and phenols, which help inhibit surface bacteria but may form harmful polycyclic aromatic hydrocarbons (PAHs) if not properly controlled. Koji inoculation leverages Aspergillus oryzae enzymes to enhance flavor and texture while naturally inhibiting spoilage microbes without producing harmful residues. Ensuring proper temperature, humidity control, and hygiene are critical for both methods to prevent contamination and maintain food safety standards in ham production. |

Related Important Terms

Cold smoke aroma modulation

Cold smoke aroma modulation in ham curing significantly differs between traditional smoke curing and koji inoculation methods, where cold smoking imparts complex phenolic and woody aromas through slow combustion of hardwoods, enhancing the product's sensory profile. Koji inoculation, by contrast, leverages enzymatic fermentation to develop umami and subtle sweetness without the smoky overlay, offering a cleaner flavor profile that can be further customized by controlled smoke exposure during cold smoking stages.

Fungal esterification

Smoke curing imparts complex phenolic compounds and antimicrobial properties to ham through controlled combustion, whereas koji inoculation leverages Aspergillus oryzae's enzymatic activity to enhance fungal esterification, producing a rich array of aromatic esters that deepen flavor profiles. The fungal esterification process in koji-inoculated hams accelerates lipid transformation, creating subtle fruity and floral notes distinct from the smoky, resinous tones developed during traditional smoke curing.

Koji umami amplification

Koji inoculation enhances ham curing by enzymatically breaking down proteins and starches, resulting in a rich umami flavor that surpasses traditional smoke curing methods. This fermentation process leverages Aspergillus oryzae to amplify amino acids and nucleotides, intensifying taste complexity and improving tenderness without introducing smoky notes.

Pyrazine-derived rind

Smoke curing develops a distinctive pyrazine-derived rind through the Maillard reaction, imparting complex roasted and nutty flavors to the ham's surface. In contrast, koji inoculation fosters enzymatic fermentation that enhances umami and sweetness without producing the smoky pyrazine compounds characteristic of traditional smoke cures.

Aspergillus oryzae proteolysis

Smoke curing imparts distinctive flavors through Maillard reactions and phenolic compounds, while koji inoculation using Aspergillus oryzae enhances ham tenderness and umami by enzymatic proteolysis, breaking down muscle proteins into peptides and free amino acids. Aspergillus oryzae proteolysis during koji-based curing accelerates flavor development and improves texture without introducing smoke-associated compounds.

Enzymatic tenderization

Smoke curing enhances ham's flavor and preservation by applying phenolic compounds and heat, which also indirectly contribute to enzymatic tenderization through protein denaturation. Koji inoculation accelerates enzymatic tenderization by introducing Aspergillus oryzae enzymes such as proteases and amylases, resulting in more pronounced breakdown of muscle fibers and improved texture compared to traditional smoke curing.

Nuka-zuke inspired cure

Smoke curing imparts a distinct smoky flavor and acts as a natural preservative by infusing ham with antimicrobial compounds from wood combustion, while koji inoculation utilizes Aspergillus oryzae enzymes to break down proteins and enhance umami depth, creating a Nuka-zuke inspired cure. This traditional Japanese rice bran fermentation method not only tenderizes the ham but also introduces complex lactic acid bacteria, promoting a unique tanginess absent in conventional smoke-cured products.

Microbial terroir development

Smoke curing imparts distinct microbial terroir through phenolic compounds and antimicrobial agents that shape surface microbiota, promoting smoke-adapted bacterial communities, while koji inoculation encourages enzymatic fermentation by Aspergillus oryzae, fostering unique microbial consortia that enhance umami complexity and proteolysis in ham. The interplay between smoke-associated microbes and koji-derived fungi results in divergent flavor profiles and safety parameters driven by microbial succession and terroir-specific biochemical transformations.

Non-thermal preservation

Smoke curing utilizes phenolic compounds and formaldehyde in smoke to inhibit microbial growth and enhance flavor through non-thermal preservation, whereas koji inoculation employs Aspergillus oryzae enzymes to ferment and tenderize ham without heat, promoting natural preservation and flavor development. Both methods rely on biochemical processes rather than high temperatures, preserving the ham's texture and extending shelf life through microbial control and enzymatic activity.

Smoke curing vs koji inoculation for ham. Infographic

cookingdiff.com

cookingdiff.com