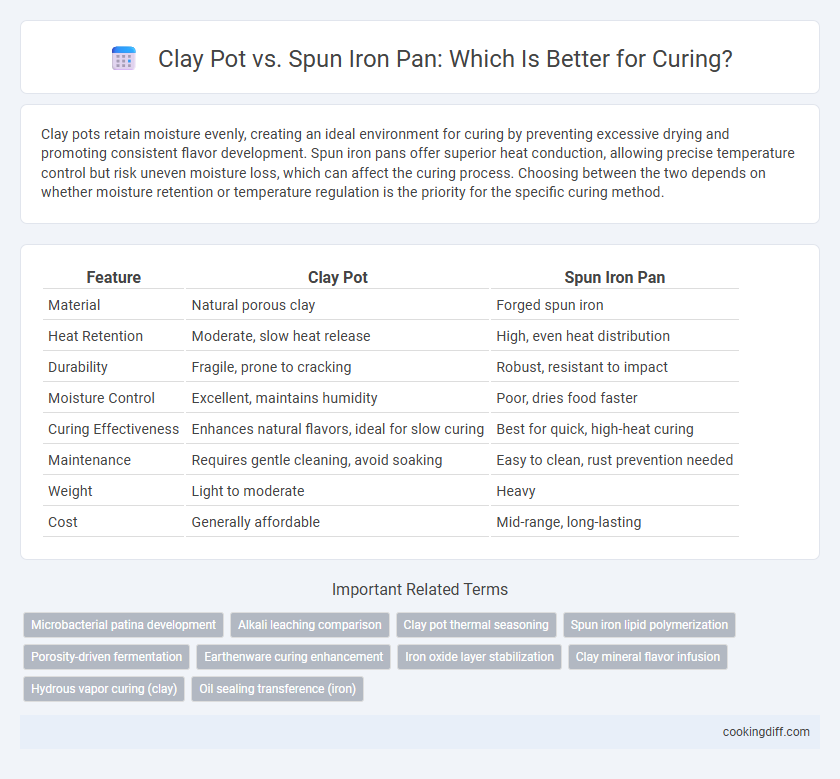

Clay pots retain moisture evenly, creating an ideal environment for curing by preventing excessive drying and promoting consistent flavor development. Spun iron pans offer superior heat conduction, allowing precise temperature control but risk uneven moisture loss, which can affect the curing process. Choosing between the two depends on whether moisture retention or temperature regulation is the priority for the specific curing method.

Table of Comparison

| Feature | Clay Pot | Spun Iron Pan |

|---|---|---|

| Material | Natural porous clay | Forged spun iron |

| Heat Retention | Moderate, slow heat release | High, even heat distribution |

| Durability | Fragile, prone to cracking | Robust, resistant to impact |

| Moisture Control | Excellent, maintains humidity | Poor, dries food faster |

| Curing Effectiveness | Enhances natural flavors, ideal for slow curing | Best for quick, high-heat curing |

| Maintenance | Requires gentle cleaning, avoid soaking | Easy to clean, rust prevention needed |

| Weight | Light to moderate | Heavy |

| Cost | Generally affordable | Mid-range, long-lasting |

Introduction to Curing in Cooking

Curing is a traditional cooking method used to preserve and enhance the flavor of food through drying, salting, or fermenting. Clay pots provide an ideal environment for curing by maintaining consistent moisture and temperature levels.

Spun iron pans, while durable and heat-retentive, tend to dry out the food faster, making them less effective for long-term curing processes. Clay pots' porous nature allows slow evaporation, crucial for developing complex flavors during curing.

Understanding Clay Pots: Properties and Benefits

What makes clay pots ideal for curing compared to spun iron pans? Clay pots are porous, allowing gradual moisture evaporation and enhancing flavor depth during curing. Their natural insulation maintains a consistent temperature, promoting even curing and preserving food quality.

Spun Iron Pans: Features and Advantages

Spun iron pans provide excellent heat retention and even distribution, which is crucial for effective curing processes. Their sturdy construction minimizes warping and ensures consistent temperatures over extended periods.

These pans are highly durable and resistant to rust when properly seasoned, making them ideal for repeated use in curing. The non-stick surface develops naturally over time, enhancing the flavor and quality of cured ingredients. Their versatility allows them to be used on various heat sources, including stovetops and ovens, optimizing curing efficiency.

Heat Retention and Distribution Comparison

Clay pots excel in heat retention, maintaining steady temperatures crucial for curing processes. Spun iron pans offer superior heat distribution, ensuring even curing across the surface.

- Clay Pot Heat Retention - Its porous material absorbs and slowly releases heat, allowing for consistent temperature over time.

- Spun Iron Heat Distribution - The dense metal conducts heat evenly, preventing hot spots and uneven curing results.

- Temperature Stability - Clay pots provide gradual temperature changes, while spun iron pans respond quickly to heat adjustments.

Flavor Impact: Clay Pot vs Spun Iron

Clay pots enhance curing by retaining moisture and imparting earthy flavors each time they're used, enriching the food's taste over time. Spun iron pans offer a more neutral flavor profile but provide excellent heat distribution, which affects curing precision and consistency.

- Moisture Retention - Clay pots maintain higher humidity levels during curing, preserving juiciness and intensifying flavor development.

- Flavor Absorption - Porous clay absorbs and releases natural food aromas, creating complex, layered tastes unique to this material.

- Heat Conductivity - Spun iron delivers even, consistent heat that supports uniform curing but lacks the flavor-enhancing properties of clay.

Moisture Control in Curing: Which is Superior?

Clay pots naturally absorb and release moisture, creating a balanced environment ideal for curing processes that demand consistent humidity levels. This porous nature aids in preventing excess moisture buildup, reducing the risk of mold during curing.

Spun iron pans, while durable, lack the ability to regulate moisture effectively as they create a sealed environment that can trap condensation. This often leads to uneven curing conditions, making clay pots superior for moisture control in curing.

Ease of Use and Maintenance

Clay pots require careful handling and gentle cleaning to avoid cracks, making maintenance more delicate compared to spun iron pans. Spun iron pans offer greater durability and are easier to clean with simple scrubbing and seasoning, ensuring long-term usability. The ease of use favors spun iron due to its resistance to damage and straightforward upkeep process.

Suitability for Different Curing Techniques

Clay pots excel in slow, even heat distribution ideal for wet curing methods, while spun iron pans provide rapid, uniform heating suitable for dry curing. The porous nature of clay enhances moisture retention during curing, whereas spun iron's durability supports high-temperature applications.

- Clay pot's porous material - retains moisture effectively, making it perfect for curing processes requiring consistent humidity.

- Spun iron pan's heat conductivity - allows precise temperature control essential for dry curing techniques.

- Durability differences - clay pots can crack under thermal shock, while spun iron pans withstand frequent heating cycles.

Choosing between a clay pot and a spun iron pan depends on the curing technique's moisture and heat requirements.

Longevity and Durability

| Clay Pot | Excellent heat retention but fragile, prone to cracking under thermal shock; requires careful handling, limiting long-term durability for curing processes. |

| Spun Iron Pan | Highly durable with superior resistance to impact and thermal stress; ensures longevity even under frequent curing cycles due to robust construction and material strength. |

Related Important Terms

Microbacterial patina development

Clay pots promote a rich microbacterial patina due to their porous surface, which enhances flavor development and natural curing processes by fostering beneficial microbial growth. Spun iron pans, being non-porous and smoother, inhibit microbacterial colonization, resulting in less complex patina formation during curing.

Alkali leaching comparison

Clay pots exhibit minimal alkali leaching during curing compared to spun iron pans, which tend to release higher levels of alkaline ions that can affect the food's pH balance. This difference makes clay pots more suitable for maintaining natural flavors and nutritional integrity in the curing process.

Clay pot thermal seasoning

Clay pot thermal seasoning enhances natural non-stick properties by slowly absorbing oils into its porous surface, creating a durable, chemical-free cure that improves heat retention and moisture distribution during cooking. Unlike spun iron pans, which require frequent re-seasoning with oil layers, clay pots develop seasoning over time through gradual temperature changes, promoting even heat flow and preserving flavor integrity.

Spun iron lipid polymerization

Spun iron pans enhance curing through accelerated lipid polymerization, creating a durable non-stick surface that improves flavor development and heat distribution. Unlike clay pots, spun iron's superior thermal conductivity and polymerized lipid layer ensure efficient curing and long-lasting seasoning.

Porosity-driven fermentation

Clay pots, with their high porosity, enable controlled moisture evaporation and oxygen exchange, fostering an ideal environment for porosity-driven fermentation during curing. In contrast, spun iron pans lack this porosity, limiting air flow and moisture regulation, which can hinder the fermentation process essential for developing complex flavors.

Earthenware curing enhancement

Earthenware clay pots provide superior curing enhancement due to their porous structure, which allows for gradual moisture evaporation and even heat distribution, promoting optimal flavor development and preservation. In contrast, spun iron pans conduct heat rapidly but lack the moisture regulation properties essential for achieving the nuanced curing effects typical of traditional clay pot methods.

Iron oxide layer stabilization

Clay pots provide a porous surface that allows gradual seasoning and moisture retention, but spun iron pans form a highly durable iron oxide layer during curing, enhancing rust resistance and creating a non-stick surface. The iron oxide stabilization in spun iron pans ensures long-term protection and improved cooking performance compared to the less stable seasoning on clay pots.

Clay mineral flavor infusion

Clay pots enhance curing by allowing slow evaporation and moisture retention, which promotes deep flavor infusion through their porous mineral composition. In contrast, spun iron pans provide even heat distribution but lack the mineral properties necessary for imparting complex, earthy undertones during the curing process.

Hydrous vapor curing (clay)

Hydrous vapor curing in clay pots creates a naturally humid environment that enhances moisture retention and even heat distribution, promoting superior seasoning and durability of cookware. In contrast, spun iron pans lack this vapor-rich environment, often resulting in uneven curing and less effective seasoning over time.

Clay pot vs spun iron pan for curing. Infographic

cookingdiff.com

cookingdiff.com