Oil curing and flaxseed polymerization both rely on oxidative cross-linking to harden oils, but oil curing typically uses drying oils like linseed or tung oil that form a durable, water-resistant finish through a faster drying process. Flaxseed polymerization involves the natural polymerization of flaxseed oil, resulting in a flexible and eco-friendly coating with slower curing times and enhanced elasticity. Choosing between them depends on desired drying speed, finish durability, and environmental considerations.

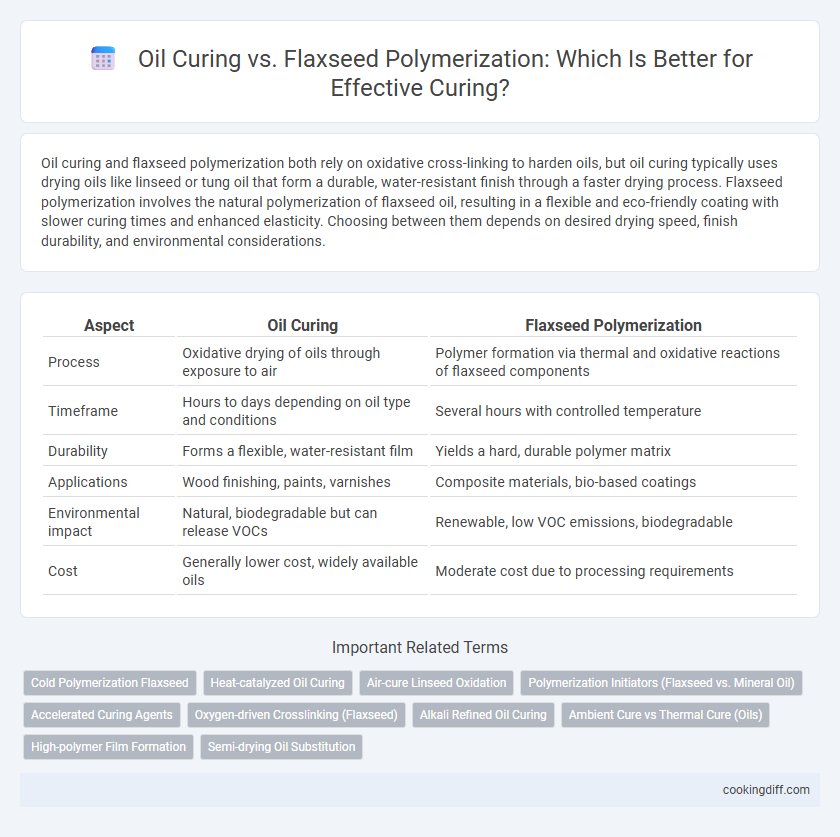

Table of Comparison

| Aspect | Oil Curing | Flaxseed Polymerization |

|---|---|---|

| Process | Oxidative drying of oils through exposure to air | Polymer formation via thermal and oxidative reactions of flaxseed components |

| Timeframe | Hours to days depending on oil type and conditions | Several hours with controlled temperature |

| Durability | Forms a flexible, water-resistant film | Yields a hard, durable polymer matrix |

| Applications | Wood finishing, paints, varnishes | Composite materials, bio-based coatings |

| Environmental impact | Natural, biodegradable but can release VOCs | Renewable, low VOC emissions, biodegradable |

| Cost | Generally lower cost, widely available oils | Moderate cost due to processing requirements |

Introduction to Curing: Oil vs. Flaxseed Polymerization

Oil curing involves the oxidation and cross-linking of unsaturated fatty acids found in drying oils such as linseed oil, resulting in a hardened, protective surface. This process relies on the presence of oxygen and metal catalysts to initiate polymerization, forming a durable film.

Flaxseed polymerization specifically refers to the curing of flaxseed oil, a type of drying oil rich in alpha-linolenic acid, which undergoes rapid oxidative cross-linking. This natural polymerization creates a solid network that is widely used in wood finishing and paint formulations for its strong adhesion and resistance properties.

Understanding Oil Curing Techniques

Oil curing involves the oxidative drying process where oils like linseed or tung oil harden upon exposure to air through polymerization. Flaxseed polymerization specifically refers to the chemical transformation in flaxseed oil that enhances the drying and curing characteristics for durable finishes.

- Oxidative Drying - Oil curing relies on atmospheric oxygen to initiate cross-linking reactions that solidify the oil film.

- Flaxseed Oil's High Linolenic Acid - The high content of polyunsaturated linolenic acid in flaxseed oil facilitates rapid polymerization and robust curing.

- Durability and Flexibility - Properly cured flaxseed oil coatings create a flexible, water-resistant surface used extensively in wood finishing and painting.

What is Flaxseed Polymerization in Cooking?

Flaxseed polymerization in cooking involves the transformation of flaxseed oil through heat, causing the fatty acids to form a solid, durable film useful for curing. This process enhances the oil's drying properties, making it ideal for preserving and finishing wooden cooking utensils or surfaces. Unlike traditional oil curing, flaxseed polymerization creates a natural, food-safe coating that hardens upon exposure to air and heat.

Key Benefits of Oil Curing

Oil curing enhances wood durability by penetrating deeply and forming a protective layer, whereas flaxseed polymerization primarily relies on surface drying. The superior water resistance and flexibility provided by oil curing contribute to longer-lasting finishes.

- Improved Penetration - Oil curing allows oils to seep into wood fibers, increasing protection against moisture and decay.

- Enhanced Flexibility - Oil-cured surfaces maintain elasticity, reducing cracking and peeling over time.

- Superior Water Resistance - Oil curing creates a hydrophobic barrier that better repels water compared to flaxseed polymerization.

Oil curing offers a more durable and resilient finish, making it ideal for outdoor and high-wear applications.

Advantages of Flaxseed Oil for Polymerization

Flaxseed oil exhibits superior drying properties compared to conventional oil curing methods due to its high content of polyunsaturated fatty acids, which enhance polymerization efficiency. Its natural composition supports a more environmentally friendly and durable finish in various curing applications.

- Higher Polyunsaturation - Flaxseed oil contains a significant amount of alpha-linolenic acid, promoting faster and more complete polymerization.

- Renewable and Biodegradable - Derived from natural sources, flaxseed oil is sustainable and decomposes without harmful residues.

- Enhanced Durability - The polymerized flaxseed oil forms a robust, flexible film resistant to cracking and environmental degradation.

Chemical Differences: Oil Curing vs. Flaxseed Polymerization

| Chemical Process | Oil Curing | Flaxseed Polymerization |

|---|---|---|

| Primary Reaction | Oxidative cross-linking of unsaturated fatty acids through exposure to oxygen, forming a hardened film. | Polymerization of linseed oil triglycerides initiated by drying agents, leading to the formation of a solid polymer network. |

| Key Compounds | Linoleic and linolenic acids undergo autoxidation creating hydroperoxides and cross-links. | Formation of covalent bonds between fatty acid chains via free radical mechanisms catalyzed by metallic driers. |

| Catalysts | Natural exposure to atmospheric oxygen; may be accelerated by metal ions such as cobalt or manganese salts. | Metal-based catalysts like cobalt, manganese, or iron salts actively promote polymer chain formation. |

Durability and Longevity of Each Curing Method

Oil curing enhances durability by forming a robust, flexible film that resists moisture and environmental wear, extending the lifespan of treated materials. Flaxseed polymerization produces a hard, cross-linked surface, offering superior longevity but may become brittle over time under harsh conditions. Choosing between oil curing and flaxseed polymerization depends on balancing flexibility for durability against hardness for long-term endurance.

Best Applications: When to Use Oil or Flaxseed Polymerization

Oil curing is ideal for wood finishes requiring deep penetration and enhanced water resistance, commonly used in outdoor furniture and flooring applications. Flaxseed polymerization suits art supplies and specialty coatings where a faster drying time and a smoother finish are essential.

Choose oil curing when durability and flexibility over time are priorities, especially in industrial settings with high moisture exposure. Flaxseed polymerization is preferred for fine art and restoration projects that demand precise control over drying speed and film hardness.

Potential Drawbacks: Oil Curing and Flaxseed Polymerization

Oil curing can lead to uneven drying and potential yellowing due to excessive oxidation, which affects the final product's appearance and durability. Flaxseed polymerization, while natural, may cause brittleness and cracking over time if the polymer network is not adequately controlled.

Oil curing often involves the risk of VOC emissions that contribute to environmental concerns and health hazards during application. Flaxseed polymerization requires precise temperature and humidity control to prevent incomplete curing and surface tackiness. Both methods can be limited by slower curing times compared to synthetic alternatives, impacting production efficiency.

Related Important Terms

Cold Polymerization Flaxseed

Cold polymerization of flaxseed oil facilitates curing through slow oxidative cross-linking of unsaturated fatty acids, enhancing the formation of a durable, flexible polymer network at lower temperatures. Unlike traditional oil curing, which relies on heat to accelerate drying, cold polymerization preserves bioactive compounds in flaxseed oil, resulting in superior environmental stability and non-toxic characteristics ideal for eco-friendly coatings.

Heat-catalyzed Oil Curing

Heat-catalyzed oil curing accelerates the oxidative polymerization of unsaturated fatty acids in drying oils like linseed, forming a durable, cross-linked film essential for paint and varnish durability. Unlike flaxseed polymerization, which relies on natural enzymatic processes, oil curing uses elevated temperatures and metal catalysts such as cobalt or manganese salts to enhance reaction rates and improve the mechanical properties of the cured coating.

Air-cure Linseed Oxidation

Air-cure linseed oxidation relies on the natural polymerization of unsaturated fatty acids in flaxseed oil, forming a durable, cross-linked film through exposure to oxygen. Oil curing accelerates this process by adding metallic driers, enhancing the rate of free radical generation and resulting in faster, more controlled film formation compared to the slower, purely oxidative polymerization of raw flaxseed oil.

Polymerization Initiators (Flaxseed vs. Mineral Oil)

Flaxseed polymerization relies on natural enzymes and polyunsaturated fatty acids as initiators, promoting oxidative cross-linking that enhances drying and durability, whereas mineral oil curing depends on synthetic catalysts that control polymer network formation without significant oxidation. The choice of initiator significantly impacts cure time, mechanical properties, and environmental sustainability of the final product.

Accelerated Curing Agents

Accelerated curing agents enhance the polymerization process in both oil curing and flaxseed polymerization by significantly reducing drying time and improving film durability. Metal-based catalysts such as cobalt, manganese, and iron salts act as effective accelerators, promoting oxidative cross-linking and improving the efficiency of curing in alkyd and oil-based coatings.

Oxygen-driven Crosslinking (Flaxseed)

Oil curing relies on oxidative crosslinking where atmospheric oxygen reacts with unsaturated fatty acids to form a hardened polymer network, while flaxseed polymerization utilizes oxygen-driven crosslinking that specifically promotes rapid formation of strong covalent bonds through polyunsaturated fatty acids, resulting in improved durability and flexibility. Flaxseed's oxygen-driven crosslinking mechanism enhances the polymer matrix by generating a more uniform and tightly bonded structure compared to traditional oil curing methods.

Alkali Refined Oil Curing

Alkali refined oil curing involves a chemical process that enhances polymerization by removing free fatty acids and impurities, resulting in a more stable and efficient drying compared to flaxseed oil curing. This method improves film hardness and oxidation resistance, making alkali refined oils preferable for high-performance coatings and industrial applications.

Ambient Cure vs Thermal Cure (Oils)

Ambient cure oils, such as linseed and flaxseed, undergo oxidative cross-linking at room temperature through exposure to oxygen, resulting in slower but energy-efficient curing ideal for coatings and wood finishes. Thermal cure oils require elevated temperatures to accelerate polymerization, producing faster curing rates and enhanced mechanical properties but increasing energy consumption and processing costs.

High-polymer Film Formation

Oil curing relies on autoxidation of unsaturated fatty acids in oils to form a high-polymer film through cross-linking, resulting in durable coatings with excellent adhesion. Flaxseed polymerization involves rapid oxidative polymerization of linolenic acid chains, producing a dense, high-polymer network film with superior mechanical strength and enhanced flexibility.

Oil Curing vs Flaxseed Polymerization for curing. Infographic

cookingdiff.com

cookingdiff.com