Traditional oil rubs, such as mineral oil or tung oil, create a durable, water-resistant finish that deeply penetrates wooden utensils, enhancing their longevity and preventing cracking. Grapeseed oil offers a natural, food-safe alternative with a light texture that absorbs rapidly, though it may require more frequent reapplication due to its quicker oxidation. Choosing between traditional oils and grapeseed oil depends on balancing ease of use, durability, and the desire for a natural finish on wooden utensils.

Table of Comparison

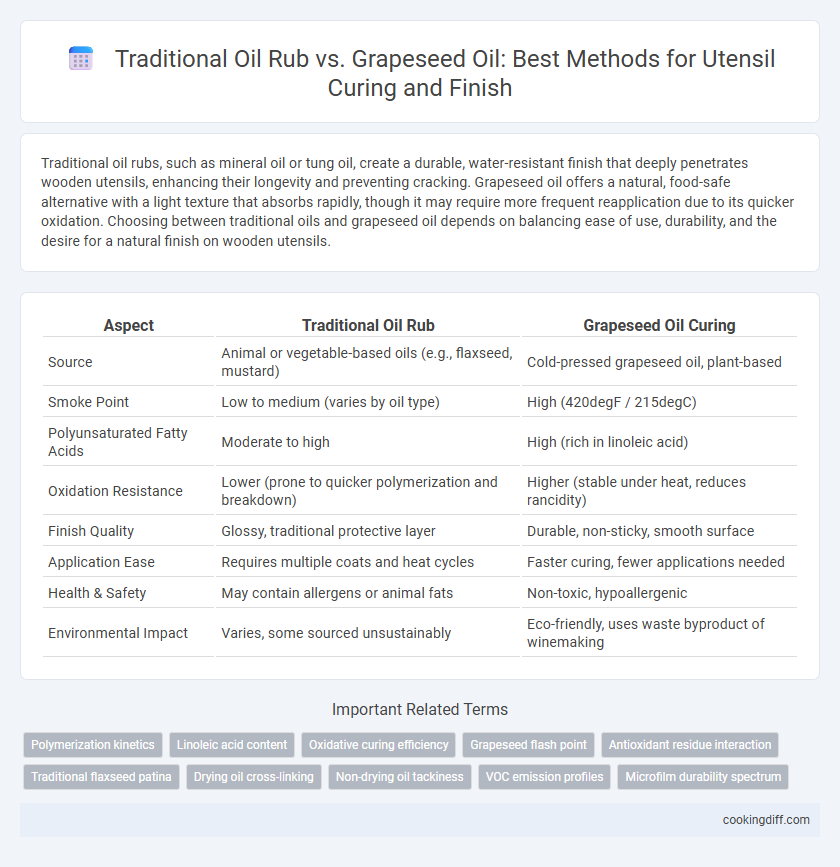

| Aspect | Traditional Oil Rub | Grapeseed Oil Curing |

|---|---|---|

| Source | Animal or vegetable-based oils (e.g., flaxseed, mustard) | Cold-pressed grapeseed oil, plant-based |

| Smoke Point | Low to medium (varies by oil type) | High (420degF / 215degC) |

| Polyunsaturated Fatty Acids | Moderate to high | High (rich in linoleic acid) |

| Oxidation Resistance | Lower (prone to quicker polymerization and breakdown) | Higher (stable under heat, reduces rancidity) |

| Finish Quality | Glossy, traditional protective layer | Durable, non-sticky, smooth surface |

| Application Ease | Requires multiple coats and heat cycles | Faster curing, fewer applications needed |

| Health & Safety | May contain allergens or animal fats | Non-toxic, hypoallergenic |

| Environmental Impact | Varies, some sourced unsustainably | Eco-friendly, uses waste byproduct of winemaking |

Introduction to Utensil Curing: Tradition Meets Modern Oils

What are the benefits of traditional oil rub compared to grapeseed oil for curing utensils? Traditional oil rubs, such as coconut or flaxseed oil, create a durable, heat-resistant coating by polymerizing under high heat, preserving the utensil's lifespan. Grapeseed oil, valued for its high smoke point and neutral flavor, provides a modern alternative that efficiently seals and protects cookware while minimizing rancidity.

Understanding Traditional Oil Rub Methods

Traditional oil rub methods for curing utensils often utilize natural oils like flaxseed or mineral oil to create a protective barrier that prevents rust and enhances durability. These oils penetrate the utensil's surface, sealing microscopic pores and providing a non-stick finish that improves with repeated applications. Understanding the differences in viscosity and drying time between traditional oils and grapeseed oil helps optimize the curing process for long-lasting utensil preservation.

Grapeseed Oil: A Modern Curing Alternative

Grapeseed oil offers a modern curing alternative with a higher smoke point and neutral flavor, making it ideal for achieving a durable finish on cooking utensils. Its rich content of polyunsaturated fats promotes faster polymerization compared to traditional oil rubs, resulting in enhanced utensil longevity.

- High Smoke Point - Grapeseed oil resists burning during curing, preserving the utensil's surface integrity.

- Neutral Flavor - It prevents imparting unwanted tastes to cookware, maintaining food purity.

- Fast Polymerization - The oil's composition accelerates the curing process, creating a robust non-stick layer efficiently.

Chemical Composition: Traditional Oils vs Grapeseed Oil

Traditional oils like flaxseed and coconut contain high levels of polyunsaturated and saturated fats, which polymerize upon heating to create a durable, non-stick finish on utensils. In contrast, grapeseed oil is rich in polyunsaturated fatty acids with a high linoleic acid content, promoting a lighter, slower polymerization process that results in a thinner, less rigid seasoning layer.

Grapeseed oil's higher smoke point compared to many traditional oils allows for curing at elevated temperatures without burning, enhancing its suitability for utensil finishes. However, its chemical structure leads to a less robust cross-linked surface, making it less ideal for heavy-duty cookware compared to oils with more saturated fat content.

Application Process: Step-by-Step Curing Techniques

Traditional oil rub curing involves warming the utensil and applying a thin layer of flaxseed or mineral oil, followed by baking it at a controlled temperature to polymerize the oil and create a durable finish. Grapeseed oil curing requires similar preparation but emphasizes multiple thin coats applied with a lint-free cloth, allowing each layer to dry thoroughly before applying the next to build a smooth, non-stick surface. Both methods benefit from consistent heating cycles, but grapeseed oil's higher smoke point provides more flexibility in reaching optimal curing temperatures without degrading the oil.

Durability and Longevity of Different Oil Finishes

| Traditional Oil Rub | Popular options like flaxseed or tung oil penetrate deeply into wooden utensils, creating a hard, protective finish that enhances durability and water resistance. Their polymerization properties provide long-lasting protection but may require multiple coats and longer curing times to achieve optimal longevity. |

| Grapeseed Oil | Grapeseed oil, often used as a natural alternative, absorbs quickly yet offers less durable protection against moisture and wear compared to traditional oils. Its lower oxidation rate means it is prone to rancidity and may need frequent reapplication to maintain the utensil's finish and longevity. |

| Durability and Longevity | Traditional oils typically outperform grapeseed oil in creating a resilient, stable finish that guards against cracking and water damage, extending the life of wooden utensils. Regular maintenance and proper curing conditions enhance longevity for all oil finishes but traditional oils remain the preferred choice for durable utensil protection. |

Safety and Food Compatibility Considerations

Traditional oil rubs often use animal fats or mineral oils that may pose allergen risks or chemical residues, impacting safety and food compatibility. Grapeseed oil is a plant-based alternative, rich in antioxidants and non-toxic, reducing the likelihood of harmful reactions when used to cure utensils.

Grapeseed oil's high smoke point and neutral flavor make it ideal for seasoning cookware without imparting unwanted tastes or toxic fumes. Its natural composition supports food safety by avoiding synthetic additives common in traditional oil rubs. Choosing grapeseed oil enhances utensil longevity while maintaining a healthier cooking environment.

Environmental and Health Impacts of Curing Oils

Traditional oil rubs often contain petroleum-based additives that can release harmful volatile organic compounds (VOCs) during curing, negatively impacting indoor air quality and health. Grapeseed oil, a natural and non-toxic alternative, provides a safer curing process with lower environmental and respiratory risks.

- VOC Emissions - Traditional oils emit higher levels of VOCs that contribute to air pollution and respiratory issues.

- Biodegradability - Grapeseed oil is biodegradable and reduces environmental contamination compared to synthetic options.

- Allergen Potential - Natural grapeseed oil minimizes allergic reactions and skin irritation often caused by chemical components in traditional oils.

Maintenance and Re-Curing: Best Practices

Traditional oil rubs create a durable, water-resistant finish that requires periodic maintenance to prevent drying and cracking. Grapeseed oil cures faster with a lighter, more natural finish but demands more frequent re-application to maintain protection.

- Durability - Traditional oils form a tougher barrier that withstands repeated use and washing better than grapeseed oil.

- Re-curing Frequency - Grapeseed oil requires re-curing every few weeks to maintain an effective protective layer.

- Application Method - Both oils benefit from heat-assisted curing, but grapeseed oil's low smoke point limits high-temperature treatment options.

Consistent maintenance and timely re-curing ensure longevity and optimal utensil performance regardless of the oil used.

Related Important Terms

Polymerization kinetics

Traditional oil rub curing relies on oils high in polyunsaturated fatty acids that undergo rapid polymerization through oxidative cross-linking, resulting in a durable, hardened surface; grapeseed oil, characterized by its moderate linoleic acid content, exhibits slower polymerization kinetics, leading to a more uniform and controlled polymer layer formation. This difference in polymerization rates impacts the utensil's final finish quality and longevity, as faster polymerization from traditional oils often creates a more brittle coating, whereas grapeseed oil's gradual curing enhances flexibility and resistance to cracking.

Linoleic acid content

Grapeseed oil, rich in linoleic acid with approximately 70% content, provides superior polymerization and a durable finish compared to traditional oils commonly used for curing utensils. The high linoleic acid concentration enhances the drying process, resulting in a more resilient and non-stick surface ideal for cookware maintenance.

Oxidative curing efficiency

Traditional oil rubs like flaxseed oil undergo a polymerization process that creates a durable, hard finish through oxidative curing, whereas grapeseed oil, with its higher polyunsaturated fat content, offers moderate oxidative curing efficiency but may result in a softer, less resilient surface. The oxidative stability and drying time of flaxseed oil typically outperform grapeseed oil, making it more effective for long-lasting utensil finishes.

Grapeseed flash point

Grapeseed oil, with a high flash point of approximately 420degF (216degC), offers superior heat resistance compared to traditional oils, making it ideal for curing utensils and ensuring a durable, non-stick finish. Its stability at high temperatures allows for effective polymerization, enhancing the utensil's surface protection and longevity.

Antioxidant residue interaction

Traditional oil rubs, rich in natural antioxidants like tocopherols and polyphenols, create a protective antioxidant residue that interacts effectively with metal surfaces to prevent oxidation and corrosion in utensil curing. Grapeseed oil, with its lower antioxidant content but higher linoleic acid concentration, forms a less stable residue that may offer reduced long-term protection against oxidative damage compared to traditional oils in utensil finishing.

Traditional flaxseed patina

Traditional flaxseed oil curing develops a durable, food-safe patina on utensils faster than grapeseed oil, promoting superior water resistance and enhanced non-stick properties. Unlike grapeseed oil, flaxseed oil polymerizes more effectively, resulting in a longer-lasting, natural finish that improves with continued use.

Drying oil cross-linking

Traditional oil rubs, such as flaxseed or tung oil, cure through a drying oil cross-linking process that polymerizes upon exposure to oxygen, creating a durable and water-resistant finish. Grapeseed oil, despite being used for seasoning utensils, lacks sufficient polyunsaturated fatty acids necessary for effective cross-linking, resulting in a weaker, less durable curing film.

Non-drying oil tackiness

Traditional oil rubs like mineral oil provide a quick protective coating but often leave a tacky, non-drying residue on utensils, reducing overall finish durability. Grapeseed oil, rich in polyunsaturated fats, offers a less sticky, more naturally drying cure that enhances utensil longevity without the greasy feel typical of non-drying oils.

VOC emission profiles

Traditional oil rubs used for curing utensils often emit higher levels of volatile organic compounds (VOCs), including aldehydes and hydrocarbons, contributing to stronger odors and indoor air pollution. Grapeseed oil curing demonstrates a lower VOC emission profile due to its natural composition, resulting in a safer and more environmentally friendly finish for kitchen utensils.

Traditional oil rub vs grapeseed oil curing for utensil finish. Infographic

cookingdiff.com

cookingdiff.com