Copper pans offer excellent heat conductivity and durability, making them ideal for even curing of ingredients, while titanium-coated pans provide a non-reactive surface that prevents metallic contamination during the curing process. Copper's natural antimicrobial properties can enhance food safety, though it requires careful maintenance to avoid tarnishing. Titanium-coated pans combine strong heat retention with easy cleaning, making them suitable for extended curing periods without altering flavor.

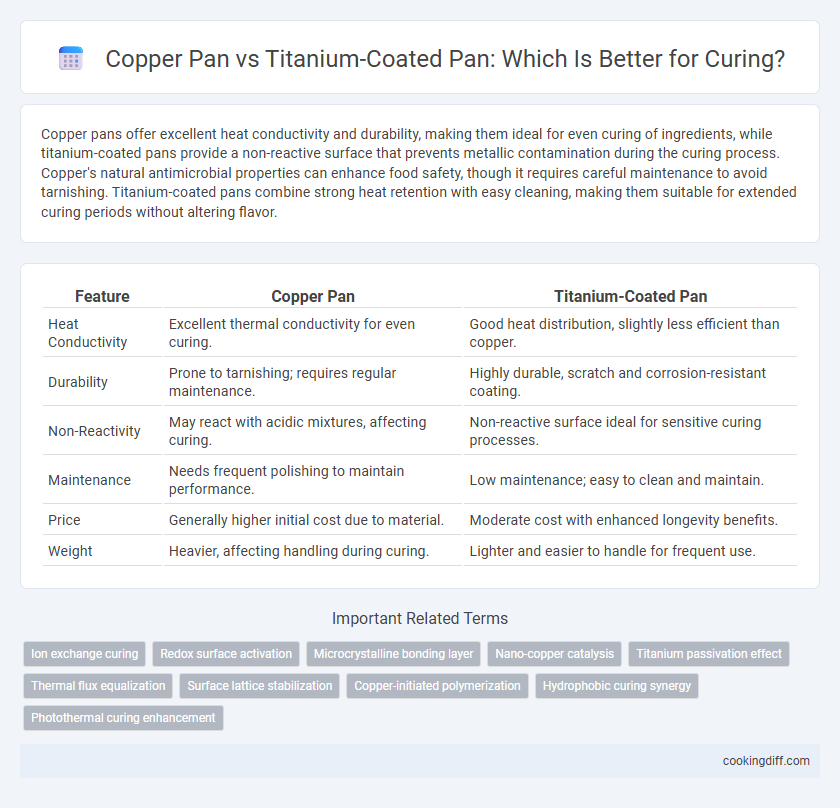

Table of Comparison

| Feature | Copper Pan | Titanium-Coated Pan |

|---|---|---|

| Heat Conductivity | Excellent thermal conductivity for even curing. | Good heat distribution, slightly less efficient than copper. |

| Durability | Prone to tarnishing; requires regular maintenance. | Highly durable, scratch and corrosion-resistant coating. |

| Non-Reactivity | May react with acidic mixtures, affecting curing. | Non-reactive surface ideal for sensitive curing processes. |

| Maintenance | Needs frequent polishing to maintain performance. | Low maintenance; easy to clean and maintain. |

| Price | Generally higher initial cost due to material. | Moderate cost with enhanced longevity benefits. |

| Weight | Heavier, affecting handling during curing. | Lighter and easier to handle for frequent use. |

Introduction to Curing in Cooking

Curing in cooking involves preserving and flavoring food through processes such as salting, smoking, or drying, demanding precise temperature control and even heat distribution. Copper pans offer superior thermal conductivity, ensuring consistent heat essential for effective curing. Titanium-coated pans provide durable, non-reactive surfaces, reducing the risk of metal contamination while maintaining adequate heat performance for curing tasks.

Understanding Copper Pans: Properties and Benefits

Copper pans offer exceptional thermal conductivity, allowing for precise temperature control essential in curing processes. Their ability to heat evenly reduces hot spots, which can prevent over-curing and preserve the product's integrity.

The high reactivity of copper also promotes faster heat transfer, making curing more efficient compared to other materials. This metal's durability and antimicrobial properties contribute to its longevity and hygiene in food preparation.

Exploring Titanium-Coated Pans: Features and Advantages

Titanium-coated pans offer superior durability and non-reactive surfaces ideal for curing sensitive ingredients, preventing metallic taste transfer often experienced with copper pans. Their enhanced scratch resistance and even heat distribution contribute to consistent curing results and longer pan lifespan.

Unlike copper pans, titanium coatings resist corrosion and require less maintenance, making them practical for frequent curing processes. The lightweight nature of titanium-coated pans also improves handling during precise temperature control essential for optimal curing performance.

Heat Conductivity: Copper vs Titanium-Coated Pans

| Heat Conductivity of Copper Pans | Copper pans exhibit exceptional thermal conductivity, typically around 401 W/m*K, allowing for rapid and even heat distribution essential for precise curing processes. |

| Heat Conductivity of Titanium-Coated Pans | Titanium-coated pans have significantly lower thermal conductivity, approximately 17 W/m*K, which can lead to slower heat transfer and less uniform temperature control during curing. |

| Impact on Curing Efficiency | Higher heat conductivity in copper pans enhances temperature accuracy and reduces curing time compared to titanium-coated pans, making copper a preferred choice for processes requiring consistent heat application. |

Reactivity and Flavor Impact in Curing

Copper pans exhibit high reactivity, which can influence the curing process by interacting with acids and enhancing flavor complexity. Titanium-coated pans offer a non-reactive surface, preserving the original taste without altering the curing outcome.

- Copper reactivity - Copper reacts with curing agents, potentially accelerating flavor development in certain recipes.

- Titanium-coated inertness - Titanium coatings prevent chemical reactions, maintaining purity and preventing metallic flavor transfer.

- Flavor impact - Copper pans can impart subtle metallic notes, while titanium-coated pans retain the intended flavor profile precisely.

Durability and Longevity: Which Pan Lasts Longer?

Copper pans are renowned for their excellent heat conductivity but can be prone to tarnishing and require regular maintenance to preserve their durability. Titanium-coated pans offer enhanced scratch resistance and corrosion protection, leading to a longer lifespan in curing applications.

- Copper Pan Durability - Copper's softness makes it susceptible to dents and scratches over time, reducing its overall longevity.

- Titanium-Coated Pan Strength - The titanium layer provides a robust barrier that resists wear and chemical damage during curing.

- Longevity Comparison - Titanium-coated pans generally last longer than copper pans due to their superior resistance to physical and chemical degradation.

Maintenance and Cleaning Comparison

How do maintenance and cleaning differ between copper pans and titanium-coated pans during curing? Copper pans require regular polishing to prevent tarnishing and maintain their conductivity, while titanium-coated pans are more resistant to staining and generally easier to clean. The non-reactive surface of titanium coatings minimizes buildup, reducing the frequency of deep cleaning compared to copper.

Safety Considerations in Curing with Different Pans

Copper pans offer excellent heat conductivity but may leach metals during curing, raising safety concerns. Titanium-coated pans provide a non-reactive surface, minimizing the risk of chemical contamination.

Choosing titanium-coated pans for curing is safer as they resist corrosion and metal transfer, ensuring food safety. Copper pans require regular maintenance and monitoring to prevent toxicity from metal exposure. Proper usage and cleaning are essential regardless of the pan type to maintain safe curing conditions.

Cost Efficiency: Investment and Value Analysis

Copper pans offer excellent heat conductivity but come with a higher initial cost and maintenance expense due to tarnishing and reactivity. Titanium-coated pans provide durability and non-reactive surfaces with lower upfront costs, making them a cost-efficient choice for long-term use in curing applications.

- Initial Investment - Copper pans typically have a higher purchase price compared to titanium-coated options.

- Maintenance Costs - Copper requires frequent polishing and careful handling to maintain performance and appearance.

- Durability Value - Titanium-coated pans offer enhanced scratch resistance and corrosion protection, reducing replacement frequency.

Choosing titanium-coated pans often results in better overall cost efficiency due to lower maintenance and longer lifespan during curing processes.

Related Important Terms

Ion exchange curing

Copper pans excel in ion exchange curing due to copper's high thermal conductivity and natural antimicrobial properties, which enhance the curing process by facilitating uniform heat distribution and reducing bacterial growth. Titanium-coated pans offer corrosion resistance and non-reactivity but have lower thermal conductivity, potentially leading to less efficient ion exchange during curing compared to copper.

Redox surface activation

Copper pans exhibit superior redox surface activation during curing due to their high electrical conductivity and ability to facilitate electron transfer, accelerating the oxidation-reduction reactions essential for curing processes. In contrast, titanium-coated pans offer enhanced durability and corrosion resistance but demonstrate lower redox activity, making copper pans more effective for applications requiring rapid and efficient surface activation.

Microcrystalline bonding layer

The microcrystalline bonding layer in copper pans ensures superior heat conductivity and even curing by promoting consistent temperature distribution. Titanium-coated pans offer enhanced durability and non-reactive surfaces, but their bonding layers typically lack the thermal efficiency critical for precise curing processes.

Nano-copper catalysis

Nano-copper catalysis in copper pans enhances the curing process by promoting faster and more uniform heat distribution, which improves reaction rates in food preservation. Titanium-coated pans, while durable and non-reactive, lack the catalytic properties of nano-copper, resulting in less efficient curing performance.

Titanium passivation effect

Titanium-coated pans offer superior curing performance due to the titanium passivation effect, which creates a stable oxide layer that prevents metal ion leaching and enhances chemical resistance. In contrast, copper pans may react with curing ingredients, potentially altering flavors and reducing the durability of the pan's surface.

Thermal flux equalization

Copper pans provide superior thermal flux equalization due to copper's high thermal conductivity, ensuring even heat distribution crucial for efficient curing processes. Titanium-coated pans offer durability and resistance to corrosion but have lower thermal conductivity, resulting in less uniform heat transfer during curing.

Surface lattice stabilization

Copper pans offer superior surface lattice stabilization due to their high thermal conductivity and ability to evenly distribute heat, which prevents warping and ensures consistent curing. Titanium-coated pans enhance durability and corrosion resistance but provide less effective lattice stabilization compared to copper, potentially leading to uneven curing results over time.

Copper-initiated polymerization

Copper pans enhance curing processes through copper-initiated polymerization, accelerating reaction rates due to copper's catalytic properties. Titanium-coated pans lack this catalytic effect, resulting in slower polymerization and less efficient curing outcomes.

Hydrophobic curing synergy

Copper pans exhibit superior thermal conductivity, enhancing the hydrophobic curing process by evenly distributing heat and promoting faster solvent evaporation, while titanium-coated pans offer a durable, non-reactive surface that synergizes with hydrophobic curing agents to maintain coating integrity and prevent moisture retention. The combination of copper's heat efficiency and titanium's protective layer optimizes curing speed and quality, maximizing the longevity and performance of hydrophobic treatments.

Copper pan vs titanium-coated pan for curing. Infographic

cookingdiff.com

cookingdiff.com