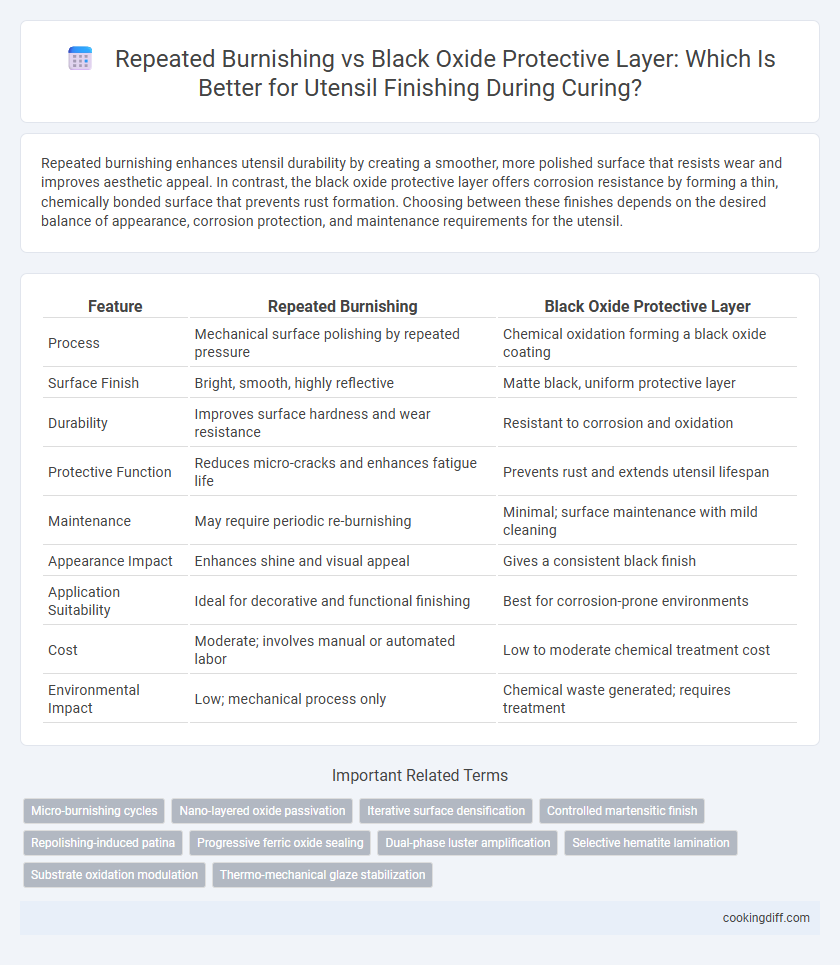

Repeated burnishing enhances utensil durability by creating a smoother, more polished surface that resists wear and improves aesthetic appeal. In contrast, the black oxide protective layer offers corrosion resistance by forming a thin, chemically bonded surface that prevents rust formation. Choosing between these finishes depends on the desired balance of appearance, corrosion protection, and maintenance requirements for the utensil.

Table of Comparison

| Feature | Repeated Burnishing | Black Oxide Protective Layer |

|---|---|---|

| Process | Mechanical surface polishing by repeated pressure | Chemical oxidation forming a black oxide coating |

| Surface Finish | Bright, smooth, highly reflective | Matte black, uniform protective layer |

| Durability | Improves surface hardness and wear resistance | Resistant to corrosion and oxidation |

| Protective Function | Reduces micro-cracks and enhances fatigue life | Prevents rust and extends utensil lifespan |

| Maintenance | May require periodic re-burnishing | Minimal; surface maintenance with mild cleaning |

| Appearance Impact | Enhances shine and visual appeal | Gives a consistent black finish |

| Application Suitability | Ideal for decorative and functional finishing | Best for corrosion-prone environments |

| Cost | Moderate; involves manual or automated labor | Low to moderate chemical treatment cost |

| Environmental Impact | Low; mechanical process only | Chemical waste generated; requires treatment |

Understanding Utensil Finishing in Curing

Repeated burnishing enhances the durability and shine of utensil surfaces by compacting the metal, resulting in improved corrosion resistance and a smoother finish. Black oxide protective layers provide a chemical barrier that prevents oxidation and rust while maintaining a matte black appearance, commonly used in stainless steel utensils. Understanding utensil finishing in curing involves evaluating these methods for their impact on longevity, aesthetics, and resistance to wear under repeated cleaning and usage conditions.

What Is Repeated Burnishing?

Repeated burnishing is a finishing process that enhances the surface texture of utensils by using successive mechanical polishing passes to create a smooth, reflective finish. This method improves durability and resistance to corrosion without adding additional chemical coatings, unlike black oxide layers.

- Surface Hardening - Repeated burnishing compresses the metal surface, increasing hardness and wear resistance.

- Corrosion Resistance - The process reduces surface imperfections, minimizing oxidation and rust formation.

- Eco-friendly - It avoids chemical treatments, offering an environmentally safer alternative to black oxide protective layers.

Burnished utensils achieve a long-lasting, visually appealing finish that maintains functionality across extended use.

The Science Behind Black Oxide Protective Layers

The black oxide protective layer forms through a chemical conversion process that creates a magnetite (Fe3O4) coating on metal surfaces, enhancing corrosion resistance and reducing light reflectivity. This thin, adherent layer improves utensil durability without significantly altering dimensions.

Repeated burnishing physically compresses the metal surface to increase hardness and smoothness but does not provide inherent corrosion protection. In contrast, the black oxide finish chemically passivates the surface, creating a stable, corrosion-resistant barrier. The synergy of both methods can optimize utensil longevity and performance by combining mechanical strength with chemical stability.

Key Differences: Burnishing vs Black Oxide Finishes

| Aspect | Repeated Burnishing | Black Oxide Protective Layer |

|---|---|---|

| Surface Finish | Creates a smooth, polished metal surface by mechanically compressing the material's peaks and valleys. | Forms a matte to semi-glossy dark coating through a chemical oxidation process that enhances corrosion resistance. |

| Durability | Improves surface hardness and wear resistance without adding a coating layer. | Provides a thin, durable layer that protects against rust, oxidation, and minor abrasion. |

| Application | Ideal for improving aesthetic and fatigue strength in utensils requiring a polished finish. | Best suited for utensils needing enhanced corrosion protection and a darker appearance. |

Performance in Cooking: Heat Resistance & Durability

Repeated burnishing enhances utensil performance by increasing surface hardness and improving heat resistance through dense metal compaction. Black oxide protective layers provide corrosion resistance and moderate heat durability but may degrade under prolonged high heat exposure. For optimal cooking durability and sustained heat resistance, burnished finishes typically outperform black oxide coatings.

Impact on Food Safety and Flavor

How do repeated burnishing and black oxide protective layers compare in their impact on food safety and flavor? Repeated burnishing enhances the utensil's surface smoothness, reducing bacterial adhesion and minimizing flavor transfer between uses. Black oxide coatings offer corrosion resistance but may pose risks of chemical leaching that could affect food safety and alter flavor profiles over time.

Maintenance Requirements for Each Finish

Repeated burnishing after utensil manufacturing enhances surface smoothness but requires frequent reapplication to maintain its finish, demanding consistent labor and time investments. The process may lead to gradual wear, necessitating regular inspections and touch-ups to preserve the aesthetic and protective qualities of the utensil.

In contrast, the black oxide protective layer offers a more durable finish with lower maintenance needs, providing corrosion resistance and a uniform matte appearance that withstands routine use. Occasional cleaning and minimal re-coating are generally sufficient to sustain the black oxide layer's integrity over extended periods.

Longevity: Which Finish Lasts Longer?

Repeated burnishing enhances utensil durability by compacting the metal surface, reducing wear over time, whereas black oxide layers provide a chemical protective barrier that resists corrosion but can degrade with heavy use. Longevity depends on application conditions, with burnishing offering superior resistance to physical abrasion and black oxide excelling in corrosion prevention.

- Repeated Burnishing - Improves surface hardness and resilience by mechanically smoothing and compressing the utensil's metal, leading to enhanced wear resistance.

- Black Oxide Protective Layer - Creates a thin, corrosion-resistant coating that protects the metal from oxidation but may erode under frequent abrasive contact.

- Comparative Longevity - Burnished finishes typically outlast black oxide coatings in high-friction environments, while black oxide preserves longevity better in chemically harsh or wet conditions.

Aesthetic Outcomes: Visual Appeal of Each Method

Repeated burnishing enhances the utensil's surface by creating a smooth, reflective finish that highlights the natural metal's luster and grain, offering a polished, high-gloss aesthetic. This method results in a visually appealing, tactile texture that often appeals to consumers seeking artisanal craftsmanship and shine.

The black oxide protective layer imparts a uniform matte or satin finish, providing a sleek, modern look by darkening the metal surface and reducing glare. This treatment enhances corrosion resistance while delivering a consistent coloration that appeals to industrial and minimalist design preferences.

Related Important Terms

Micro-burnishing cycles

Micro-burnishing cycles enhance the surface hardness and wear resistance of utensils by inducing compressive stresses that refine the metal grain structure, outperforming black oxide protective layers in durability. Repeated burnishing reduces surface porosity and improves corrosion resistance, making it a superior finishing method for long-lasting utensil performance.

Nano-layered oxide passivation

Repeated burnishing enhances utensil durability by mechanically compressing the surface, creating a smooth finish that reduces corrosion sites, while black oxide protective layers provide chemical resistance through nano-layered oxide passivation, forming an ultra-thin, uniform barrier that inhibits oxidation and improves wear resistance. Nano-layered oxide passivation in black oxide treatments offers superior protection by establishing a dense, tightly bound layer at the atomic scale, extending utensil lifespan under harsh conditions compared to traditional mechanical burnishing methods.

Iterative surface densification

Repeated burnishing enhances utensil finishing through iterative surface densification, producing a smoother and harder surface by compressing metal layers and reducing micro-porosity. In contrast, a black oxide protective layer provides corrosion resistance without altering the metal's microstructure or improving mechanical durability through densification.

Controlled martensitic finish

Repeated burnishing creates a controlled martensitic finish by mechanically refining the utensil's surface, enhancing hardness and wear resistance without altering its chemical composition. In contrast, a black oxide protective layer provides corrosion resistance through a chemical conversion coating but does not achieve the same degree of surface hardness or microstructural control as burnishing.

Repolishing-induced patina

Repeated burnishing enhances the utensil's surface by creating a smooth, reflective patina through mechanical work, which gradually develops a unique, polished finish but may wear away protective layers over time. In contrast, a black oxide protective layer provides long-lasting corrosion resistance and uniform appearance without altering the metal's surface texture, minimizing repolishing-induced patina but lacking the distinct aesthetic appeal of burnished finishes.

Progressive ferric oxide sealing

Repeated burnishing enhances utensil durability by compacting the surface and promoting a dense ferric oxide layer, which progressively seals micro-pores against corrosion. In contrast, a black oxide protective layer provides an immediate barrier but may lack the self-repairing properties of ferric oxide sealing developed through continuous burnishing.

Dual-phase luster amplification

Repeated burnishing enhances utensil surfaces by mechanically compressing the metal, creating a dual-phase luster amplification that combines a mirror-like shine with a subtle matte texture for improved aesthetic appeal and durability. In contrast, a black oxide protective layer chemically alters the surface to provide corrosion resistance with a uniform dark finish but lacks the dynamic light-reflective properties achieved through dual-phase burnishing.

Selective hematite lamination

Selective hematite lamination enhances the protective qualities of black oxide layers by providing a uniform, corrosion-resistant finish that improves utensil durability. Repeated burnishing, while smoothing surfaces, cannot achieve the same level of selective hematite deposition critical for long-lasting black oxide protection.

Substrate oxidation modulation

Repeated burnishing enhances substrate oxidation modulation by mechanically compressing the surface, creating a dense, work-hardened layer that reduces oxidation rates and improves corrosion resistance. In contrast, a black oxide protective layer chemically modifies the substrate surface to form a stable, uniform film that inhibits oxidation and extends the utensil's lifespan by providing consistent barrier protection.

Repeated burnishing vs black oxide protective layer for utensil finishing. Infographic

cookingdiff.com

cookingdiff.com