Classic smoke curing imparts a distinct smoky flavor and acts as a natural preservative by drying and infusing vegetables with phenolic compounds that inhibit bacterial growth. Koji mold curing utilizes Aspergillus oryzae to ferment vegetables, enhancing umami flavors while breaking down proteins and starches for improved texture and digestibility. Both methods extend shelf life, but koji mold curing offers a more complex, savory profile without the smoky notes characteristic of traditional smoke curing.

Table of Comparison

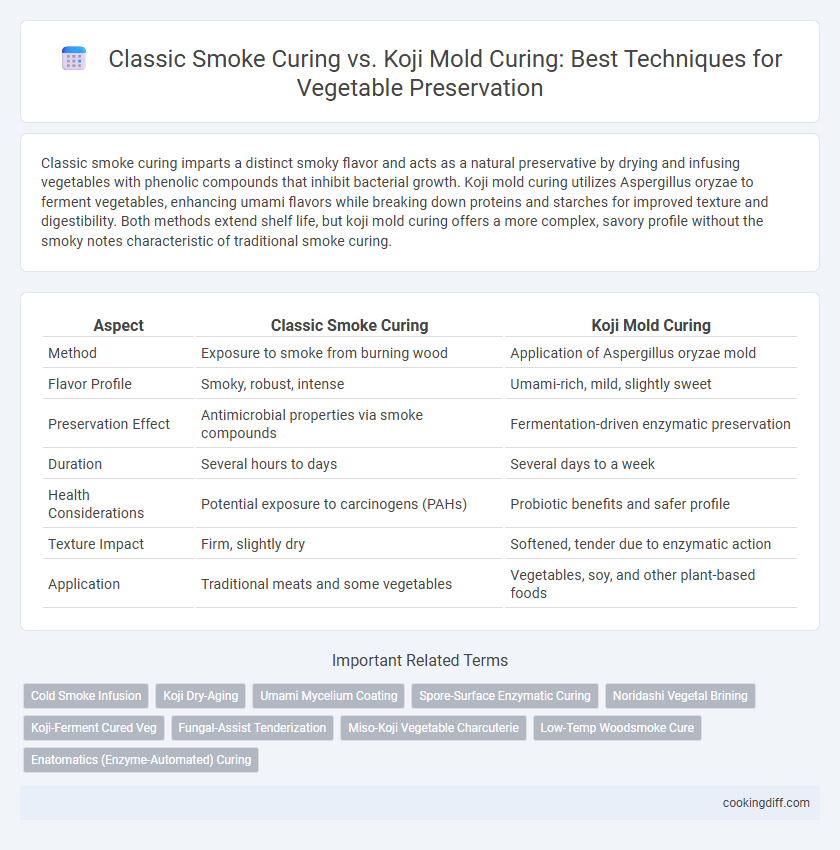

| Aspect | Classic Smoke Curing | Koji Mold Curing |

|---|---|---|

| Method | Exposure to smoke from burning wood | Application of Aspergillus oryzae mold |

| Flavor Profile | Smoky, robust, intense | Umami-rich, mild, slightly sweet |

| Preservation Effect | Antimicrobial properties via smoke compounds | Fermentation-driven enzymatic preservation |

| Duration | Several hours to days | Several days to a week |

| Health Considerations | Potential exposure to carcinogens (PAHs) | Probiotic benefits and safer profile |

| Texture Impact | Firm, slightly dry | Softened, tender due to enzymatic action |

| Application | Traditional meats and some vegetables | Vegetables, soy, and other plant-based foods |

Introduction to Vegetable Curing Methods

Vegetable curing enhances flavor, texture, and preservation using diverse traditional and modern methods. Classic smoke curing imparts a deep smoky aroma, while koji mold curing introduces umami-rich enzymatic fermentation.

- Classic Smoke Curing - Involves exposing vegetables to controlled smoke that infuses phenolic compounds, extending shelf life and adding complex flavors.

- Koji Mold Curing - Utilizes Aspergillus oryzae to enzymatically break down starches and proteins, enhancing sweetness and savory notes without smoke.

- Purpose and Outcome - Both methods aim to preserve vegetables but differ significantly in flavor profiles, texture changes, and microbial interactions.

What is Classic Smoke Curing?

| Classic Smoke Curing | A preservation technique where food is exposed to smoke from burning wood, imparting flavor and antimicrobial properties. It inhibits bacterial growth and reduces moisture content, extending shelf life of vegetables. This method relies on phenols, formaldehyde, and other compounds in smoke to prevent spoilage effectively. |

Understanding Koji Mold Curing

Koji mold curing utilizes Aspergillus oryzae to ferment vegetables, enhancing umami flavors and breaking down starches into simpler sugars. This traditional Japanese method differs from classic smoke curing, which imparts smoky aromas and preserves vegetables through exposure to wood smoke. Koji curing offers a unique probiotic boost and softer texture, making it a healthier alternative to smoke curing for vegetable preservation.

Historical Roots: Smoke vs Koji Curing

What are the historical roots of classic smoke curing compared to koji mold curing for vegetables? Classic smoke curing dates back thousands of years and was primarily developed to preserve meat and fish using wood smoke, imparting distinct flavors and antimicrobial properties. Koji mold curing, originating in East Asia over a millennium ago, utilizes Aspergillus oryzae to ferment and enhance the umami flavors of vegetables, emphasizing enzymatic breakdown rather than direct preservation by smoke.

Flavor Profiles: Smoky vs Umami-Rich Vegetables

Classic smoke curing imparts a deep smoky flavor that enhances the natural sweetness of vegetables, creating a robust and savory profile. Koji mold curing, on the other hand, develops complex umami-rich flavors through enzymatic fermentation, intensifying the vegetable's inherent taste.

- Classic Smoke Curing - Uses wood smoke to infuse vegetables with aromatic compounds, resulting in a bold, smoky aroma and taste.

- Koji Mold Curing - Employs Aspergillus oryzae mold to break down proteins and starches, producing glutamates that enrich umami flavors.

- Flavor Contrast - Smoke curing emphasizes robust, earthy notes while koji mold curing highlights savory, slightly sweet, and tangy elements.

Texture and Preservation Differences

Classic smoke curing imparts a firm, slightly drier texture to vegetables while infusing them with smoky flavors, enhancing preservation through antimicrobial properties of smoke compounds. Koji mold curing, by contrast, softens vegetables due to enzymatic breakdown, creating a tender texture and promoting preservation via fermentation acids and bioactive peptides.

Smoke curing significantly reduces moisture content, extending shelf life through dehydration and phenolic antioxidants. Koji mold curing relies on controlled fermentation, developing complex umami flavors and preserving vegetables with natural acids and enzymes, but resulting in a shorter shelf life compared to smoke curing.

Nutritional Impact of Each Curing Method

Classic smoke curing introduces antioxidants such as phenols into vegetables, enhancing preservation while slightly reducing heat-sensitive vitamins like vitamin C. This method also imparts a smoky flavor, which may affect nutrient bioavailability differently compared to raw vegetables.

Koji mold curing promotes enzymatic fermentation that increases levels of beneficial amino acids and vitamins, particularly B-complex vitamins, boosting the nutritional profile of vegetables. The fermentation process also improves digestibility and may introduce probiotics, contributing to gut health.

Equipment and Ingredient Requirements

Classic smoke curing requires traditional equipment such as smokers or smokehouses, along with wood chips or sawdust to generate smoke, and primarily uses salt as a curing agent. Koji mold curing involves a controlled environment with humidity and temperature regulation devices, plus the cultivation of Aspergillus oryzae mold and steamed grains to inoculate vegetables.

Smoke curing demands a longer curing time and vigilant monitoring of smoke density and temperature to achieve desired flavor and preservation effects. Koji mold curing relies on biochemical processes that break down starches and proteins, requiring precise control of mold growth and substrate conditions. Both methods have distinct equipment and ingredient needs tailored to their curing mechanisms, impacting texture and taste outcomes in vegetables.

Culinary Applications and Recipe Ideas

Classic smoke curing imparts a deep, smoky flavor and preserves vegetables through exposure to wood smoke, ideal for enhancing root vegetables and peppers in hearty stews or grilled dishes. Koji mold curing uses enzymatic fermentation to develop umami-rich, tender textures, perfect for pickled cucumbers and fermented soy products in Asian-inspired recipes. Both methods offer unique flavor profiles and can be creatively combined to elevate vegetable-based culinary applications.

Related Important Terms

Cold Smoke Infusion

Cold smoke infusion preserves the crisp texture and vibrant color of vegetables by exposing them to low-temperature smoke, preventing spoilage while imparting subtle smoky flavors. Unlike koji mold curing, which relies on enzymatic fermentation to develop umami and sweetness, classic smoke curing emphasizes mild phenolic compounds from wood smoke to enhance flavor without altering moisture content.

Koji Dry-Aging

Koji dry-aging uses Aspergillus oryzae mold enzymes to break down vegetable starches and proteins, enhancing umami flavor and texture with natural fermentation processes. Unlike classic smoke curing, koji curing provides a smokeless, savory depth while preserving vegetable nutrients and reducing harmful compounds from combustion.

Umami Mycelium Coating

Classic smoke curing enhances vegetables with smoky phenols and caramelized sugars, delivering a rich and complex flavor profile, while koji mold curing with Umami Mycelium Coating promotes enzymatic fermentation that intensifies natural umami through amino acid and peptide development. The Umami Mycelium Coating also fosters a tender texture and unique savory depth by cultivating beneficial microbes distinct from the oxidative effects of traditional smoking.

Spore-Surface Enzymatic Curing

Classic smoke curing relies on phenolic compounds and antimicrobial agents from wood smoke to preserve vegetables, while koji mold curing utilizes spore-surface enzymatic activity to break down complex carbohydrates and proteins, enhancing flavor and texture through natural fermentation. Spore-surface enzymes such as amylases and proteases in koji mold accelerate curing by hydrolyzing starches and proteins, promoting umami and tenderization without the carcinogenic byproducts associated with smoke curing.

Noridashi Vegetal Brining

Classic smoke curing imparts a rich, smoky flavor to vegetables through slow exposure to wood smoke, preserving them with natural antimicrobial properties. Noridashi vegetal brining using koji mold enhances umami by enzymatically breaking down vegetable proteins and sugars, offering a unique, savory depth without the use of smoke.

Koji-Ferment Cured Veg

Koji mold curing enhances vegetable preservation by promoting enzymatic fermentation, resulting in complex umami flavors and improved nutritional profiles compared to traditional classic smoke curing methods. This fermentation process increases digestibility and introduces beneficial probiotics, making koji-ferment cured vegetables a superior choice for health-conscious consumers seeking depth in taste and texture.

Fungal-Assist Tenderization

Classic smoke curing uses phenolic compounds and heat to tenderize vegetables by breaking down cell walls, while koji mold curing employs enzymes like proteases and amylases produced by Aspergillus oryzae to enzymatically digest proteins and starches, resulting in enhanced fungal-assist tenderization. Koji mold curing offers more precise control over texture and flavor development through microbial enzymatic activity compared to the oxidative effects of traditional smoke curing.

Miso-Koji Vegetable Charcuterie

Classic smoke curing imparts deep, smoky flavors and preservative properties through the application of wood smoke, while koji mold curing utilizes Aspergillus oryzae enzymes to ferment and enhance umami complexity in vegetables. Miso-Koji vegetable charcuterie leverages koji's fermentation to develop rich, savory profiles and improved texture, offering a healthier alternative to traditional smoke-cured products.

Low-Temp Woodsmoke Cure

Low-temp woodsmoke curing imparts a distinct smoky aroma and natural preservative qualities by slowly exposing vegetables to controlled, low-temperature smoke from hardwoods, aiding in moisture reduction and flavor development. In contrast, koji mold curing enhances umami and enzymatic breakdown through microbial fermentation, offering a milder, tangy complexity without the intense smoky profile characteristic of classic smoke curing.

Classic smoke curing vs koji mold curing for vegetables. Infographic

cookingdiff.com

cookingdiff.com