Seasoned cast iron woks offer superior heat retention and a naturally non-stick surface ideal for curing, creating a durable cooking vessel that develops rich flavors over time. Carbon steel woks heat up faster and provide greater responsiveness to temperature changes but require more frequent seasoning to maintain their protective coating. For effective curing, cast iron's robust seasoning layer ensures long-lasting performance while carbon steel demands diligent upkeep to prevent rust and maintain its cooking properties.

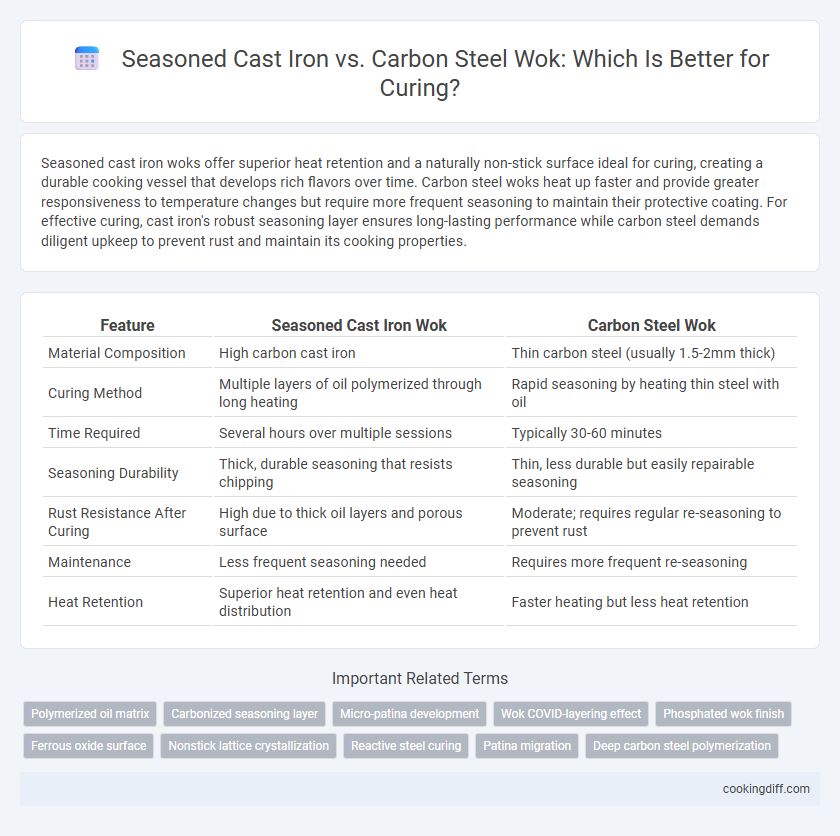

Table of Comparison

| Feature | Seasoned Cast Iron Wok | Carbon Steel Wok |

|---|---|---|

| Material Composition | High carbon cast iron | Thin carbon steel (usually 1.5-2mm thick) |

| Curing Method | Multiple layers of oil polymerized through long heating | Rapid seasoning by heating thin steel with oil |

| Time Required | Several hours over multiple sessions | Typically 30-60 minutes |

| Seasoning Durability | Thick, durable seasoning that resists chipping | Thin, less durable but easily repairable seasoning |

| Rust Resistance After Curing | High due to thick oil layers and porous surface | Moderate; requires regular re-seasoning to prevent rust |

| Maintenance | Less frequent seasoning needed | Requires more frequent re-seasoning |

| Heat Retention | Superior heat retention and even heat distribution | Faster heating but less heat retention |

Introduction: Curing and Its Importance in Cookware

Curing is a crucial process that enhances the durability and non-stick properties of cookware, especially seasoned cast iron and carbon steel woks. Seasoned cast iron develops a stable, polymerized oil layer that prevents rust and improves cooking performance over time. Carbon steel woks benefit from curing by forming a protective patina, which also boosts heat retention and flavor development during cooking.

Understanding Seasoned Cast Iron Woks

Seasoned cast iron woks develop a natural non-stick surface through repeated curing, enhancing flavor retention and heat distribution. The porous surface of cast iron absorbs seasoning oils, creating a durable coating that improves with use.

- Durability - Cast iron woks withstand high temperatures and resist warping, making them ideal for long-term use.

- Heat Retention - They retain heat evenly, allowing consistent cooking temperatures and better searing.

- Maintenance - Proper curing prevents rust and food sticking, requiring regular seasoning with oil.

Understanding these features helps in choosing a wok that benefits most from the curing process for optimal cooking performance.

Properties of Carbon Steel Woks

| Property | Carbon Steel Wok |

|---|---|

| Weight | Lighter than cast iron, enabling easier handling during curing and cooking. |

| Heat Conductivity | Heats up quickly and evenly, promoting efficient seasoning and consistent cooking temperatures. |

| Surface Texture | Smoother than cast iron, which allows for a more uniform patina to develop during curing. |

| Reactivity | More reactive to acidic foods, requiring proper curing to prevent rust and maintain durability. |

| Maintenance | Requires regular seasoning and careful drying to preserve the non-stick layer developed through curing. |

Curing Process: Cast Iron vs Carbon Steel

The curing process for seasoned cast iron involves repeated heating with oil to build a durable, non-stick patina that enhances rust resistance and cooking performance. Carbon steel woks require a similar seasoning method, but their thinner material heats faster, allowing the oil to polymerize more quickly and create a smooth surface.

Cast iron's slower heat distribution demands longer curing times to develop an even protective layer, while carbon steel benefits from multiple short seasoning sessions for optimal results. Both materials rely on high heat and oil polymerization, but carbon steel's responsiveness offers a quicker, more flexible curing experience compared to the robust, enduring patina formed on cast iron.

Heat Retention and Distribution Comparison

Seasoned cast iron woks excel in heat retention, maintaining consistent temperatures ideal for curing processes. Carbon steel woks, while heating up faster, distribute heat more evenly but cool down quicker, affecting curing performance.

- Heat Retention - Cast iron's dense material stores heat longer, ensuring steady curing temperatures.

- Heat Distribution - Carbon steel provides rapid, uniform heating across the wok surface for even curing.

- Cooling Rate - Carbon steel cools faster than cast iron, potentially causing temperature fluctuations during curing.

Surface Nonstick Qualities After Curing

Seasoned cast iron woks develop a thick, durable nonstick patina that improves with use, providing excellent surface resistance to food sticking after thorough curing. This seasoning is highly stable, offering superior heat retention and a naturally slick cooking surface that enhances flavor over time.

Carbon steel woks cure faster and achieve a smoother, more reactive surface that is less brittle than cast iron, promoting quick formation of a nonstick layer through polymerized oils. Their lighter weight and higher responsiveness to seasoning contribute to easier food release and efficient heat conductivity during cooking.

Durability and Maintenance Needs

Seasoned cast iron woks offer superior durability due to their thicker construction and resistance to warping, making them ideal for long-term curing. Carbon steel woks require more frequent maintenance to prevent rust and maintain their seasoning but heat up faster and are lighter. Proper curing and regular oiling significantly extend the lifespan of both materials, though cast iron demands less frequent upkeep compared to carbon steel.

Flavor Development: Which Wok Excels?

Seasoned cast iron woks develop a rich, non-stick surface through layers of polymerized oil, enhancing the depth of flavor by retaining seasoning oils from previous dishes. Carbon steel woks, while quicker to cure, create a thinner seasoning that allows for a brighter, more neutral flavor profile.

Flavor development in seasoned cast iron woks excels in creating complex, well-rounded tastes due to its porous surface that absorbs and melds oils and spices over time. Carbon steel woks excel in high-heat stir-frying, imparting a subtle smoky aroma that enhances the natural flavors of ingredients without overpowering them. Choosing between the two depends on whether deeper seasoning or versatile, quick cooking is prioritized for flavor extraction.

Common Mistakes in Curing Each Type

What are common mistakes made when curing seasoned cast iron versus carbon steel woks? Seasoned cast iron often suffers from improper heating that leads to uneven seasoning and sticky surfaces, while carbon steel woks are prone to rusting if not dried thoroughly after curing. Both materials require careful temperature control and regular maintenance to ensure a durable, non-stick patina.

Related Important Terms

Polymerized oil matrix

Seasoned cast iron woks develop a thicker polymerized oil matrix due to their porous surface, enhancing non-stick properties and corrosion resistance over time. Carbon steel woks form a thinner but harder polymerized layer that heats up faster and is easier to re-season, offering superior heat responsiveness and durability during curing.

Carbonized seasoning layer

Carbon steel woks develop a thicker, more uniform carbonized seasoning layer compared to seasoned cast iron, enhancing natural non-stick properties and resistance to rust. This carbonized layer forms through repeated curing cycles, fostering superior durability and heat responsiveness essential for wok cooking.

Micro-patina development

Seasoned cast iron woks develop a thicker, more durable micro-patina due to their porous surface, which enhances seasoning layers and improves non-stick properties over time. Carbon steel woks form a thinner, more reactive micro-patina that offers quicker seasoning and greater responsiveness to temperature changes for precise cooking control.

Wok COVID-layering effect

Seasoned cast iron retains a thicker, more robust polymerized seasoning layer that enhances the Wok COVID-layering effect, providing superior non-stick properties and corrosion resistance during curing. Carbon steel woks develop a thinner, more reactive patina that requires frequent re-seasoning to maintain optimal COVID-layering benefits and prevent rust formation.

Phosphated wok finish

A phosphated wok finish on seasoned cast iron provides a durable, rust-resistant surface ideal for effective curing and long-term maintenance, while carbon steel woks typically develop a natural, non-toxic patina suited for high-heat cooking and easier seasoning. The phosphating process enhances adhesion of seasoning layers on cast iron, promoting quicker build-up of a non-stick surface compared to carbon steel's reliance on repeated oil polymerization during curing.

Ferrous oxide surface

Seasoned cast iron develops a thick ferrous oxide layer that enhances its non-stick properties and durability during curing, while carbon steel woks form a thinner, more uniform ferrous oxide surface that allows faster seasoning but requires more frequent maintenance. The ferrous oxide's texture and adherence on cast iron provide long-term protection against rust, contrasting with carbon steel's reactive surface which benefits from repeated curing cycles to build up stable oxide layers.

Nonstick lattice crystallization

Seasoned cast iron and carbon steel woks both develop nonstick lattice crystallization during curing, but carbon steel forms this polymerized seasoning faster due to its smoother surface and lower alloy content. The crystalline structure in cast iron offers durability and superior heat retention, while carbon steel provides a more flexible, quicker seasoning process ideal for high-heat stir-frying.

Reactive steel curing

Seasoned cast iron woks develop a thick, durable patina ideal for non-stick performance through repeated oil polymerization, while carbon steel woks cure faster due to their reactive steel surface that bonds more efficiently with seasoning oils, enhancing heat responsiveness and corrosion resistance. Reactive steel's molecular structure accelerates the formation of a stable, blackened seasoning layer, making carbon steel woks preferred for dynamic cooking techniques like stir-frying.

Patina migration

Seasoned cast iron woks develop a thick, stable patina that offers superior resistance to rust and enhances flavor over time, while carbon steel woks form a thinner, more reactive patina that migrates quickly across the surface during curing. Patina migration in carbon steel allows for faster seasoning cycles but requires more frequent maintenance compared to the durable, slow-forming patina of cast iron.

Seasoned cast iron vs carbon steel wok for curing. Infographic

cookingdiff.com

cookingdiff.com