Dry curing bacon involves rubbing salt and curing agents directly onto the meat, allowing moisture to be drawn out over time, which intensifies flavor and creates a firmer texture. Equilibrium curing uses a controlled brine solution with precise salt concentrations, enabling the meat to reach a balanced moisture and salt content evenly throughout without over-curing. This method results in consistent seasoning and a more tender, juicier bacon compared to the sometimes saltier and denser outcome of dry curing.

Table of Comparison

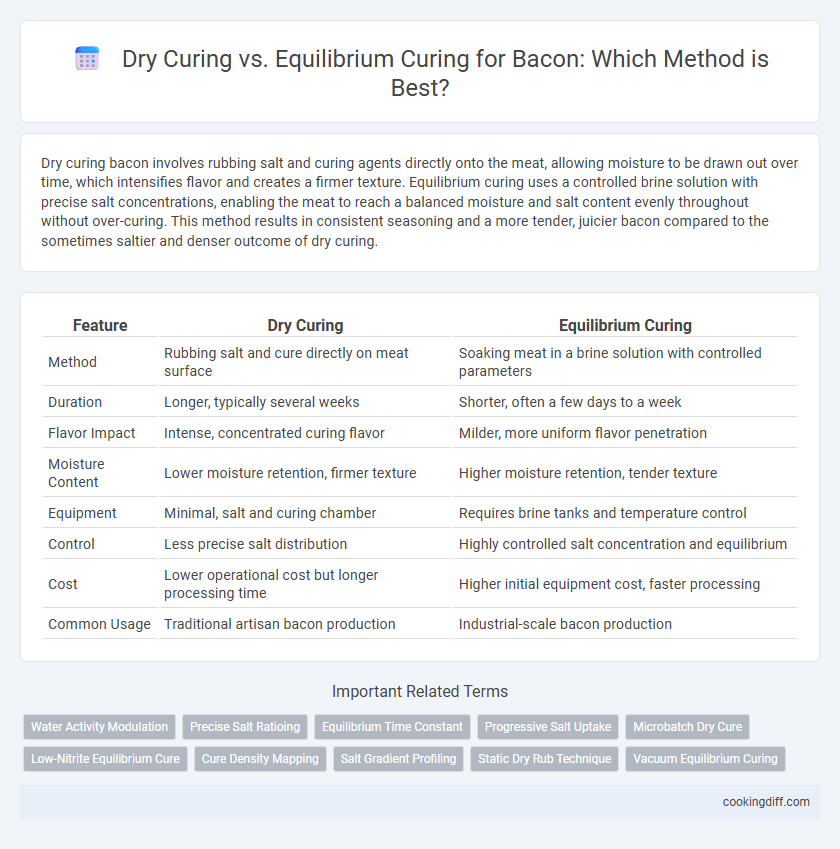

| Feature | Dry Curing | Equilibrium Curing |

|---|---|---|

| Method | Rubbing salt and cure directly on meat surface | Soaking meat in a brine solution with controlled parameters |

| Duration | Longer, typically several weeks | Shorter, often a few days to a week |

| Flavor Impact | Intense, concentrated curing flavor | Milder, more uniform flavor penetration |

| Moisture Content | Lower moisture retention, firmer texture | Higher moisture retention, tender texture |

| Equipment | Minimal, salt and curing chamber | Requires brine tanks and temperature control |

| Control | Less precise salt distribution | Highly controlled salt concentration and equilibrium |

| Cost | Lower operational cost but longer processing time | Higher initial equipment cost, faster processing |

| Common Usage | Traditional artisan bacon production | Industrial-scale bacon production |

Understanding Dry Curing and Equilibrium Curing for Bacon

What are the key differences between dry curing and equilibrium curing for bacon? Dry curing involves rubbing salt and spices directly onto the meat, drawing out moisture while intensifying flavors over several days. Equilibrium curing uses a controlled brine injection or soaking process, ensuring consistent salt distribution and faster curing times without dehydration.

The Science Behind Dry Curing Bacon

Dry curing bacon involves applying a precise mixture of salt and curing agents directly onto the meat's surface, allowing osmosis to remove moisture and infuse flavor, which enhances preservation and texture. Equilibrium curing uses a brine solution where the meat absorbs a calculated amount of salt and cure based on weight, ensuring consistent distribution and curing stability. The science behind dry curing emphasizes salt concentration, osmotic pressure, and protein denaturation, which collectively inhibit microbial growth and develop the characteristic bacon flavor and firmness.

How Equilibrium Curing Differs from Traditional Methods

Equilibrium curing uses precise brine concentrations to ensure uniform salt and curing agent penetration in bacon, contrasting with traditional dry curing, which relies on surface application and slower diffusion. This method reduces the risk of under- or over-curing, resulting in consistent flavor and texture throughout the meat.

In equilibrium curing, bacon is submerged in a carefully balanced brine until the curing agents are evenly absorbed, while dry curing involves rubbing dry salt mixtures directly on the meat's surface. This controlled process accelerates curing time and enhances food safety by minimizing bacterial growth during curing.

Ingredients Used in Dry Curing vs Equilibrium Curing

Dry curing uses a mixture of salt, sugar, nitrates, and spices directly applied to the surface of the bacon, promoting gradual moisture loss and intense flavor development. Equilibrium curing involves soaking bacon in a brine containing precise levels of salt, sugar, sodium nitrite, and other curing agents, ensuring uniform absorption while maintaining product moisture. Specific ingredient ratios and curing durations vary between methods, impacting the texture and taste profile of the final bacon product.

Step-by-Step Process: Dry Curing Bacon

Dry curing bacon involves rubbing a precise mixture of salt, sugar, and curing agents directly onto the meat, ensuring even absorption and flavor development. The meat is then tightly wrapped and refrigerated for several days, allowing the cure to penetrate and preserve the bacon thoroughly.

After curing, excess moisture is drained, and the bacon is rinsed before being air-dried to form a pellicle, which enhances smoke adhesion during cooking. This step-by-step dry curing process contrasts with equilibrium curing, where meat is submerged in a brine to achieve balance in salt concentration over time.

Step-by-Step Process: Equilibrium Curing Bacon

Equilibrium curing bacon involves applying a precise amount of cure based on the bacon's weight, ensuring uniform salt penetration and flavor distribution. This method requires sealing the bacon in airtight packaging to prevent moisture loss during the curing period.

The process begins by calculating the cure percentage according to the weight of the pork belly, typically using 2-3% curing salt by weight. Next, the cure is evenly rubbed onto the meat surface before placing the belly into vacuum-sealed bags to promote equilibrium diffusion. Finally, the bacon is refrigerated for 5 to 14 days, allowing the cure to fully penetrate the meat without drying it out.

Flavor and Texture Differences: Dry Cured vs Equilibrium Cured Bacon

| Flavor | Dry curing intensifies bacon's flavor by concentrating salts and spices on the meat's surface, creating a more robust and complex taste profile. Equilibrium curing offers a milder, more uniform flavor due to the balanced absorption of curing solution throughout the meat. |

|---|---|

| Texture | Dry cured bacon develops a firmer, drier texture with a distinct chewiness, while equilibrium cured bacon maintains a moister, softer consistency because of the even moisture distribution during curing. |

Salt Content and Safety Considerations

Dry curing bacon involves applying a salt mixture directly to the meat, resulting in higher surface salt concentration and better preservation. Equilibrium curing soaks the meat in a brine until salt levels stabilize, offering more uniform salt distribution but requiring careful time management to ensure safety.

- Salt Content Variability - Dry curing produces a gradient of salt concentration, with more salt near the surface compared to equilibrium curing's consistent internal salt level.

- Microbial Safety - The high surface salt in dry curing inhibits bacterial growth effectively, whereas equilibrium curing depends on thorough brine penetration and timing to prevent microbial risks.

- Process Control - Equilibrium curing requires monitoring salt equilibrium to avoid under-curing, while dry curing relies on the curing time and salt quantity to achieve safe preservation.

Time and Efficiency: Which Curing Method is Best for Home Cooks?

Dry curing bacon requires significantly more time, often several weeks, making it less efficient for home cooks seeking quick results. Equilibrium curing uses a precise brine concentration to reduce curing time to just a few days, enhancing efficiency and consistency.

- Dry curing time - Typically takes 1 to 3 weeks, allowing flavors to deeply penetrate the meat.

- Equilibrium curing speed - Achieves full cure within 4 to 7 days due to controlled salt and cure distribution.

- Home cook efficiency - Equilibrium curing is more practical for home kitchens where time and space are limited.

Equilibrium curing offers the best balance of flavor development and time efficiency for home cooks preparing bacon.

Related Important Terms

Water Activity Modulation

Dry curing reduces water activity by directly infusing salt and seasonings into the meat, promoting moisture loss and inhibiting microbial growth more effectively. Equilibrium curing modulates water activity by balancing salt diffusion and moisture retention, resulting in a more controlled, uniform curing process for bacon.

Precise Salt Ratioing

Dry curing bacon requires a precise salt ratio to ensure optimal flavor and preservation, as salt is directly applied to the meat surface allowing gradual absorption. Equilibrium curing uses a standardized salt concentration in a brine solution to evenly penetrate the bacon, maintaining consistent salt levels throughout the curing process.

Equilibrium Time Constant

Equilibrium curing uses the equilibrium time constant to determine when salt and curing agents uniformly penetrate the bacon, ensuring consistent flavor and preservation throughout the meat. Unlike dry curing, which relies on surface application and slower diffusion, equilibrium curing accelerates the process by accurately predicting the curing endpoint based on the meat's diffusion properties and curing environment.

Progressive Salt Uptake

Dry curing bacon involves applying a salt mixture directly to the meat surface, resulting in a slower, progressive salt uptake that enhances flavor concentration and texture. Equilibrium curing achieves uniform salt distribution more rapidly by submerging the meat in a brine solution, promoting consistent curing but with less pronounced flavor development compared to the gradual salt diffusion in dry curing.

Microbatch Dry Cure

Microbatch dry cure offers precise control over salt concentration and curing time, enhancing flavor development and texture consistency in bacon compared to traditional dry curing methods. Equilibrium curing relies on achieving a stable balance between meat and curing solution, whereas microbatch dry cure allows targeted ingredient ratios in small batches to optimize moisture retention and superior cured meat quality.

Low-Nitrite Equilibrium Cure

Low-nitrite equilibrium curing for bacon involves maintaining a constant nitrite concentration throughout the meat, ensuring safer preservation and more consistent flavor compared to traditional dry curing, which relies on salt and nitrites applied on the surface. This method reduces the risk of nitrite depletion and uneven curing, resulting in improved shelf life and reduced formation of harmful nitrosamines.

Cure Density Mapping

Dry curing achieves uniform flavor penetration by applying a concentrated salt mixture directly to the bacon surface, creating distinct zones of high cure density that inhibit microbial growth effectively. Equilibrium curing relies on osmotic balance, resulting in more even distribution of cure agents within the meat, optimizing moisture retention and consistent salt diffusion detectable through advanced cure density mapping techniques.

Salt Gradient Profiling

Dry curing creates a pronounced salt gradient in bacon due to direct salt application, resulting in a more concentrated cure on the surface that gradually diffuses inward. Equilibrium curing achieves a uniform salt distribution by submerging bacon in a curing solution until the internal salt concentration stabilizes, minimizing salt gradient profiling.

Static Dry Rub Technique

Static dry rub technique in dry curing bacon involves applying a precise, consistent layer of curing salts and spices directly to the meat's surface, allowing controlled moisture loss and flavor penetration. This method contrasts with equilibrium curing by eliminating liquid interaction, resulting in a firmer texture and more concentrated taste profile in the final product.

Dry curing vs equilibrium curing for bacon. Infographic

cookingdiff.com

cookingdiff.com