Dry curing involves applying a mixture of salt, sugar, and spices directly onto the meat's surface, promoting moisture loss and enhancing flavor through natural enzymatic reactions. EQ curing utilizes a vacuum or controlled environment to evenly distribute curing agents and accelerate the process, resulting in more consistent texture and reduced curing times. Both methods preserve meat effectively but differ in texture development, flavor intensity, and processing efficiency.

Table of Comparison

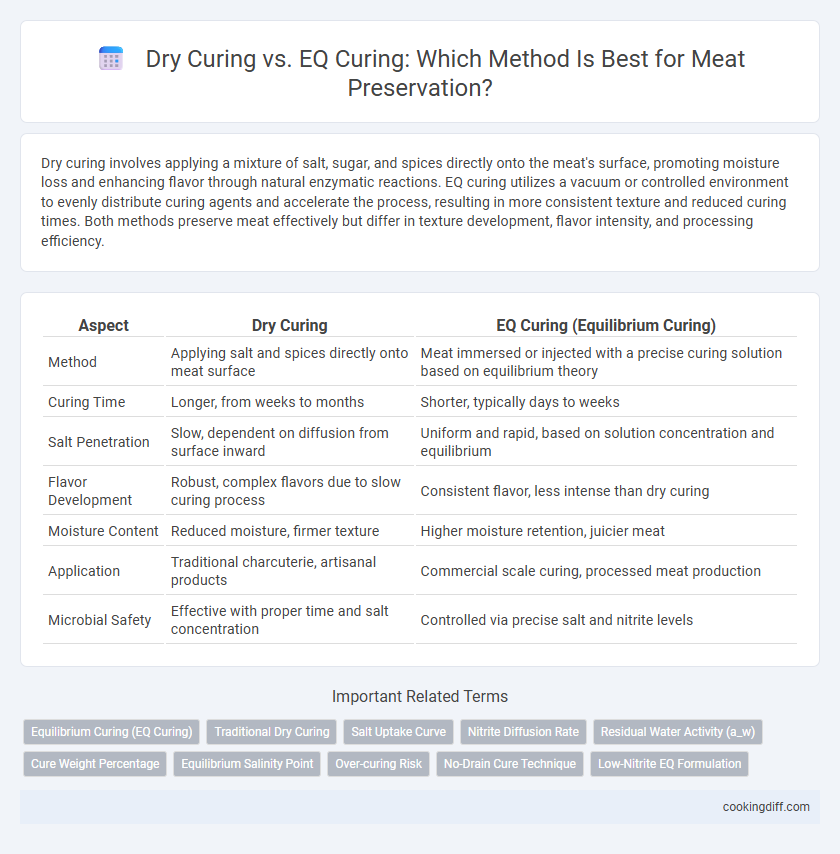

| Aspect | Dry Curing | EQ Curing (Equilibrium Curing) |

|---|---|---|

| Method | Applying salt and spices directly onto meat surface | Meat immersed or injected with a precise curing solution based on equilibrium theory |

| Curing Time | Longer, from weeks to months | Shorter, typically days to weeks |

| Salt Penetration | Slow, dependent on diffusion from surface inward | Uniform and rapid, based on solution concentration and equilibrium |

| Flavor Development | Robust, complex flavors due to slow curing process | Consistent flavor, less intense than dry curing |

| Moisture Content | Reduced moisture, firmer texture | Higher moisture retention, juicier meat |

| Application | Traditional charcuterie, artisanal products | Commercial scale curing, processed meat production |

| Microbial Safety | Effective with proper time and salt concentration | Controlled via precise salt and nitrite levels |

Introduction to Meat Curing Methods

Dry curing involves applying a dry mixture of salt and spices directly onto the meat's surface, promoting moisture loss and flavor development through dehydration. EQ curing uses a combination of salt, water, and curing agents injected or soaked into the meat to ensure even distribution and faster curing.

Both methods aim to inhibit bacterial growth and enhance preservation by lowering water activity in the meat. Dry curing typically requires longer processing times and results in a more intense, concentrated flavor, making it ideal for products like prosciutto or traditional hams. EQ curing offers greater control over moisture content and uniformity, often used in industrial production for consistent results across large batches.

What is Dry Curing?

Dry curing is a traditional meat preservation method that uses a precise mixture of salt, sugar, and spices rubbed directly onto the meat's surface. This process extracts moisture and intensifies flavor through dehydration and enzymatic reactions.

- Salt Penetration - Salt gradually infiltrates the meat, inhibiting bacterial growth and drawing out moisture.

- Texture Enhancement - Dry curing firms the meat's texture by reducing water content and promoting protein denaturation.

- Flavor Development - Extended curing times allow natural enzymes to break down proteins and fats, creating complex flavors.

Dry curing requires careful control of temperature and humidity to achieve safe and desirable results.

What is EQ (Equilibrium) Curing?

| EQ (Equilibrium) curing is a method where meat is cured using a precise balance of salt and moisture, ensuring uniform penetration of cure throughout the product. This technique maintains a consistent moisture content, preventing over-salting and textural changes typical in dry curing. EQ curing creates evenly flavored, tender meat by controlling the rate of salt diffusion until the product reaches equilibrium between cure and meat moisture. |

Ingredients and Salt Ratios for Each Method

Dry curing involves rubbing meat with a precise mixture of salt, sugar, and nitrates; the salt ratio typically ranges from 2% to 3.5% of the meat's weight, ensuring moisture is drawn out to preserve and flavor the product. Ingredients often include salt, curing salt (such as Prague powder #1), and spices tailored for specific flavors.

EQ curing, a wet brining process, uses a solution with approximately 5% to 10% salt concentration, combined with sugar and curing agents dissolved in water for uniform penetration. This method allows more consistent salt and flavor absorption, often including phosphates and other tenderizers to enhance texture and shelf life.

Step-by-Step Process: Dry Curing

Dry curing involves applying a precise mixture of salt and spices directly onto the meat's surface to preserve and flavor it without the addition of liquid. This method contrasts with EQ curing, which uses a liquid brine for faster penetration and consistent moisture distribution.

- Preparation - The meat is trimmed and weighed to calculate the exact amount of dry cure blend needed for optimal preservation.

- Application - The dry cure mixture is evenly rubbed onto the meat, ensuring full coverage for thorough curing.

- Resting - The meat is placed in a controlled environment, typically refrigerated, to allow the cure to penetrate deeply over a period of days to weeks.

Step-by-Step Process: EQ Curing

What are the precise steps involved in EQ curing meat? EQ curing involves carefully layering the meat with a blend of salt, sugar, and curing agents before vacuum-sealing it to ensure even flavor penetration and moisture retention. The sealed meat is then refrigerated for a specific period, allowing the curing agents to uniformly distribute and develop the desired taste and texture.

Time and Temperature Requirements

Dry curing requires a longer time, often several weeks to months, at lower temperatures typically between 34degF and 40degF to allow gradual moisture loss and flavor development. EQ curing accelerates the process by combining carefully controlled temperature and humidity, usually around 38degF to 45degF, with injected curing solutions, reducing curing time to days or weeks. Maintaining precise temperature control is crucial in both methods to prevent spoilage and achieve optimal meat texture and safety.

Flavor and Texture Differences

Dry curing meat intensifies its flavor through prolonged salt exposure, enhancing complexity and a firmer texture. EQ curing, or equalized curing, distributes cure ingredients evenly, producing a more consistent flavor and a tender texture.

- Dry curing enhances flavor complexity - Concentrated salt draws moisture out, concentrating the meat's natural flavors over time.

- EQ curing ensures uniform seasoning - Even distribution of cure prevents flavor hotspots and supports balanced taste throughout.

- Texture differs with curing methods - Dry curing results in a dense, chewy texture while EQ curing typically yields a softer, more pliable meat.

Safety Considerations in Curing

Dry curing involves applying salt directly to the meat, reducing moisture to inhibit bacterial growth, while EQ curing uses an equalizing solution to control salt content and moisture balance. Safety considerations emphasize preventing Clostridium botulinum and Listeria monocytogenes by maintaining appropriate salt concentrations and temperatures throughout the curing process. Proper monitoring and adherence to curing guidelines ensure effective microbial control and reduce the risk of foodborne illnesses in both methods.

Related Important Terms

Equilibrium Curing (EQ Curing)

Equilibrium Curing (EQ Curing) ensures precise control of salt and curing agent absorption in meat by achieving an osmotic balance between the curing solution and the meat's internal environment. This method significantly reduces curing time while maintaining consistent flavor distribution and texture compared to traditional dry curing techniques.

Traditional Dry Curing

Traditional dry curing involves applying salt and spices directly onto the meat's surface, allowing moisture to be drawn out gradually, which enhances flavor complexity and texture. This method contrasts with EQ curing, which uses a controlled equilibrium process for moisture and salt content, often resulting in a faster but less artisanal product.

Salt Uptake Curve

Dry curing involves direct application of salt to meat, resulting in a slower, more controlled salt uptake curve that enhances flavor development and texture over an extended period. EQ curing uses a vacuum tumbling process to accelerate salt penetration, producing a rapid salt uptake curve that ensures uniform seasoning and reduced curing time.

Nitrite Diffusion Rate

Dry curing involves applying salt and nitrites directly to the meat's surface, resulting in a slower nitrite diffusion rate that enhances flavor development and texture over time. EQ curing uses a vacuum tumbling process to accelerate nitrite penetration, ensuring uniform curing and reduced processing time while maintaining safety and quality.

Residual Water Activity (a_w)

Dry curing results in lower residual water activity (a_w) compared to EQ curing, enhancing microbial safety and shelf life in meat products. EQ curing maintains higher a_w levels, which can preserve texture and moisture but requires stricter control to prevent spoilage.

Cure Weight Percentage

Dry curing typically involves applying a concentrated mixture of salt and seasoning directly to the meat's surface, resulting in a cure weight percentage of approximately 3-6%. EQ curing, or equilibrium curing, uses a brine solution ensuring the meat absorbs the cure evenly, often achieving a precise cure weight percentage of 2-4%, optimizing flavor penetration and moisture retention.

Equilibrium Salinity Point

Dry curing involves applying salt directly to meat surfaces, relying on salt diffusion until equilibrium salinity is reached internally, which can result in uneven salt distribution and longer curing times. EQ curing, or Equilibrium curing, uses a brine solution calculated to match the meat's equilibrium salinity point, achieving uniform salt concentration more rapidly and improving consistency in flavor and preservation.

Over-curing Risk

Dry curing meat involves applying salt directly to the surface, allowing gradual moisture loss and flavor development, but it carries a higher over-curing risk due to uneven salt penetration. EQ curing uses controlled humidity and vacuum technology to evenly distribute curing agents, significantly reducing the likelihood of over-curing while maintaining optimal texture and taste.

No-Drain Cure Technique

Dry curing involves applying a direct salt mixture to meat, drawing out moisture naturally and intensifying flavor without the need for additional water, whereas EQ curing employs a no-drain cure technique that injects a precise brine solution, ensuring consistent curing and enhanced moisture retention throughout the meat. The no-drain cure technique in EQ curing optimizes texture and shelf life by allowing the brine to remain within the meat, preventing the dryness often associated with traditional dry curing.

Dry curing vs EQ curing for meat. Infographic

cookingdiff.com

cookingdiff.com