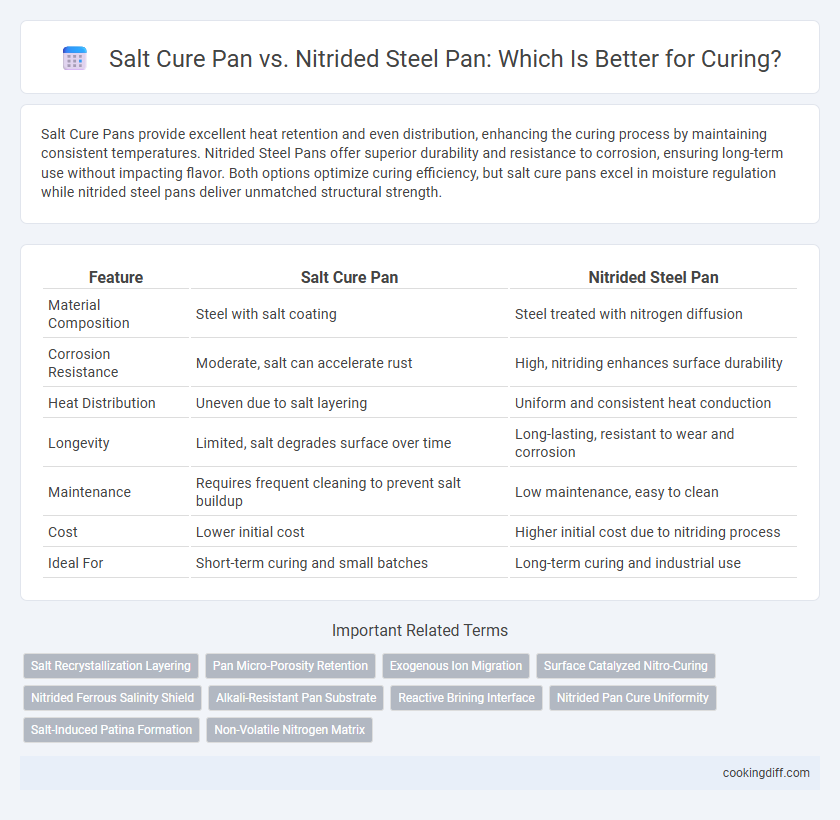

Salt Cure Pans provide excellent heat retention and even distribution, enhancing the curing process by maintaining consistent temperatures. Nitrided Steel Pans offer superior durability and resistance to corrosion, ensuring long-term use without impacting flavor. Both options optimize curing efficiency, but salt cure pans excel in moisture regulation while nitrided steel pans deliver unmatched structural strength.

Table of Comparison

| Feature | Salt Cure Pan | Nitrided Steel Pan |

|---|---|---|

| Material Composition | Steel with salt coating | Steel treated with nitrogen diffusion |

| Corrosion Resistance | Moderate, salt can accelerate rust | High, nitriding enhances surface durability |

| Heat Distribution | Uneven due to salt layering | Uniform and consistent heat conduction |

| Longevity | Limited, salt degrades surface over time | Long-lasting, resistant to wear and corrosion |

| Maintenance | Requires frequent cleaning to prevent salt buildup | Low maintenance, easy to clean |

| Cost | Lower initial cost | Higher initial cost due to nitriding process |

| Ideal For | Short-term curing and small batches | Long-term curing and industrial use |

Introduction to Curing: Salt Cure Pan vs Nitrided Steel Pan

Salt cure pans provide a traditional method for curing by using salt to draw moisture and enhance flavor, while nitrided steel pans offer a modern alternative featuring a hardened surface that resists corrosion and improves heat distribution. Choosing between salt cure pans and nitrided steel pans depends on the desired curing efficiency, durability, and maintenance requirements.

- Salt Cure Pan Composition - Made from materials that allow direct salt contact, facilitating effective moisture extraction during curing.

- Nitrided Steel Durability - Enhanced steel treated with nitrogen, resulting in superior hardness and resistance to wear and corrosion.

- Curing Efficiency - Salt cure pans excel in traditional moisture retention, while nitrided steel pans provide even heat distribution for consistent curing results.

Material Composition: Salt Cure Pan Explained

Salt cure pans are specifically designed with natural salt crystals embedded in their surface, enhancing the curing process by drawing out moisture effectively. These pans differ significantly from nitrided steel pans, which undergo a nitrogen infusion process to create a hard, corrosion-resistant layer without salt integration.

- Salt Composition - Salt cure pans utilize coarse, natural salt for moisture absorption and preservation during curing.

- Surface Texture - The salt crystals provide a unique abrasive texture that helps in extracting liquids from meats and vegetables.

- Corrosion Resistance - Unlike nitrided steel pans that rely on nitrogen for rust prevention, salt cure pans depend on the desiccating properties of salt to inhibit spoilage.

This distinct material composition makes salt cure pans ideal for traditional curing methods that require sustained moisture control.

What is a Nitrided Steel Pan? Key Features and Benefits

| Feature | Description |

|---|---|

| Material Composition | Nitrided steel pans undergo a nitriding process that infuses nitrogen into the surface, creating a hard, corrosion-resistant layer. |

| Durability | The nitrided surface enhances resistance to wear, scratches, and rust, extending the pan's lifespan compared to traditional salt cure pans. |

| Heat Retention | Nitrided steel offers excellent thermal conductivity, providing even heat distribution essential for consistent curing results. |

| Non-reactive Surface | The treated surface prevents chemical reactions with curing agents, ensuring food safety and preserving flavor integrity. |

| Maintenance | Easier to clean and maintain than salt cure pans due to its smooth, impervious finish that resists mold and residue buildup. |

| Use Cases | Ideal for professional curing applications that require durability and precision, outperforming conventional salt cure pans in performance. |

Heat Retention: Comparing Salt Cure and Nitrided Steel Pans

Salt cure pans provide superior heat retention due to the dense salt layer, ensuring even and consistent cooking temperatures ideal for curing processes. Nitrided steel pans, while durable and resistant to corrosion, tend to dissipate heat more quickly, which can result in less stable curing environments.

Salt cure pans trap heat effectively, maintaining consistent warmth crucial for slow and thorough curing of meats and other products. In contrast, nitrided steel pans cool down faster, potentially causing temperature fluctuations that may affect curing quality. Selecting the appropriate pan depends on the required heat retention and precision for the curing method employed.

Chemical Reactions: Salt Cure vs. Nitrided Steel in Curing

How do chemical reactions differ between salt cure pans and nitrided steel pans during curing? Salt cure pans utilize sodium chloride's osmotic properties to draw moisture out, promoting protein denaturation and flavor development through ionic interactions. Nitrided steel pans, coated with nitrogen to enhance surface hardness, minimize reactive metal ions, thus reducing unwanted oxidative reactions and improving cure consistency.

Durability and Longevity: Which Pan Lasts Longer?

Salt cure pans exhibit exceptional corrosion resistance, making them highly durable for prolonged curing processes, while nitrided steel pans offer enhanced surface hardness that resists wear and abrasion effectively. The nitriding process creates a hardened layer on the steel pan, extending its lifespan by preventing rust and physical damage during repeated use. Comparative studies reveal that nitrided steel pans typically last longer than salt cure pans in high-frequency curing environments due to their superior structural integrity and resistance to chemical degradation.

Flavor Impact: Does Pan Material Affect the Cure?

Salt cure pans enhance flavor by slowly drawing out moisture, intensifying the natural taste of the cured product. Their porous surface allows for subtle salt infusion that can improve overall seasoning complexity.

Nitrided steel pans provide a non-reactive, durable surface that preserves purity of flavor without imparting any metallic taste during curing. This material ensures consistent heat distribution, which aids in even curing without altering the product's original profile.

Maintenance and Cleaning: Salt Cure vs Nitrided Steel Pans

Salt cure pans require frequent rinsing and drying to prevent salt corrosion and residue buildup, which can compromise the curing process. Nitrided steel pans offer enhanced durability with a corrosion-resistant surface, minimizing maintenance demands and allowing for easier cleaning with mild detergents.

While salt cure pans may develop rust spots if not properly maintained, nitrided steel pans maintain their structural integrity longer under regular use. The non-porous finish of nitrided steel also reduces bacterial retention, promoting a more hygienic curing environment compared to salt cure options.

Cost Analysis: Which Curing Pan Offers Better Value?

Salt cure pans generally have a lower upfront cost compared to nitrided steel pans, making them more accessible for small-scale curing operations. Nitrided steel pans offer superior durability and resistance to corrosion, reducing long-term replacement and maintenance expenses. Evaluating the total cost of ownership, nitrided steel pans tend to provide better value for large-scale or frequent curing processes due to their extended lifespan and performance efficiency.

Related Important Terms

Salt Recrystallization Layering

Salt cure pans enhance curing through efficient salt recrystallization layering, promoting uniform moisture extraction and superior preservation. Nitrided steel pans offer durability and resistance to corrosion but provide less effective salt recrystallization, resulting in slower curing processes compared to salt cure pans.

Pan Micro-Porosity Retention

Salt cure pans exhibit higher micro-porosity retention compared to nitrided steel pans, enhancing moisture absorption and the curing process by maintaining a consistent surface texture. Nitrided steel pans, with reduced micro-porosity due to their hardened, smooth surface, offer less effective moisture regulation, potentially impacting the uniformity and quality of the cure.

Exogenous Ion Migration

Salt cure pans promote efficient exogenous ion migration due to their porous structure, enabling enhanced diffusion of curing salts into meat. Nitrided steel pans, with their dense, non-porous surface, limit ion migration, resulting in slower and less uniform curing processes.

Surface Catalyzed Nitro-Curing

Salt cure pans create a highly saline environment that accelerates surface-catalyzed nitro-curing by promoting ionic diffusion and enhancing the formation of nitroso compounds. Nitrided steel pans offer superior durability and a chemically active surface that catalyzes uniform nitride layer development, improving curing efficiency and meat preservation.

Nitrided Ferrous Salinity Shield

Nitrided steel pans provide superior corrosion resistance and enhanced durability compared to traditional salt cure pans, thanks to the nitrided ferrous salinity shield that prevents salt-induced degradation during curing processes. This advanced surface treatment minimizes metal ion leaching and maintains structural integrity, ensuring a consistent, high-quality cure for salt-sensitive applications.

Alkali-Resistant Pan Substrate

Salt cure pans require an alkali-resistant pan substrate to prevent corrosion and maintain structural integrity during prolonged exposure to high-salinity curing solutions. Nitrided steel pans provide superior alkali resistance compared to standard steel, ensuring enhanced durability and consistent curing performance in salt-heavy environments.

Reactive Brining Interface

Salt cure pans create a highly reactive brining interface by facilitating direct salt penetration, which accelerates protein denaturation and moisture extraction. In contrast, nitrided steel pans offer a less reactive surface that slows salt diffusion, resulting in a gentler and more controlled curing process.

Nitrided Pan Cure Uniformity

Nitrided steel pans provide superior cure uniformity during salt curing due to their enhanced surface hardness and corrosion resistance, which prevents uneven salt absorption and food sticking. This consistent curing environment ensures more reliable flavor development and texture compared to traditional salt cure pans.

Salt-Induced Patina Formation

Salt cure pans promote the formation of a natural, salt-induced patina through continuous exposure to salt crystals, which enhances corrosion resistance and develops unique flavor profiles in cured foods. Nitrided steel pans, while offering superior hardness and wear resistance, typically lack the same dynamic patina formation, resulting in less interaction between the salt and pan surface during the curing process.

Salt Cure Pan vs Nitrided Steel Pan for curing. Infographic

cookingdiff.com

cookingdiff.com